KeroZen

Chronic vapaholic

The best measurement for the 14/20 joint taper I could measure was about 3.8 degrees.

AFAIK the only thing that is really universal in the "standard taper" is the taper itself, so you shouldn't have to measure it. Cf >> https://en.wikipedia.org/wiki/Ground_glass_joint

"The conically tapered ground glass joints typically have a 1:10 taper and are often labeled with a symbol consisting of a capital T overlaid on a capital S, meaning "Standard Taper". This symbol is followed by a number, a slash, and another number. The first number represents the outer diameter (OD) in millimeters (mm) at the widest point of the inner (male) joint. The second number represents the ground glass length of the joint in millimeters."

You can see where the male stem ends, just a tiny bit above the screen.

But I'm a bit worried by the compatibility issue. Many joints have a different length (ISO vs US for instance) and some are even designed to have the tip of the male part protrude lower than the bottom of the female.

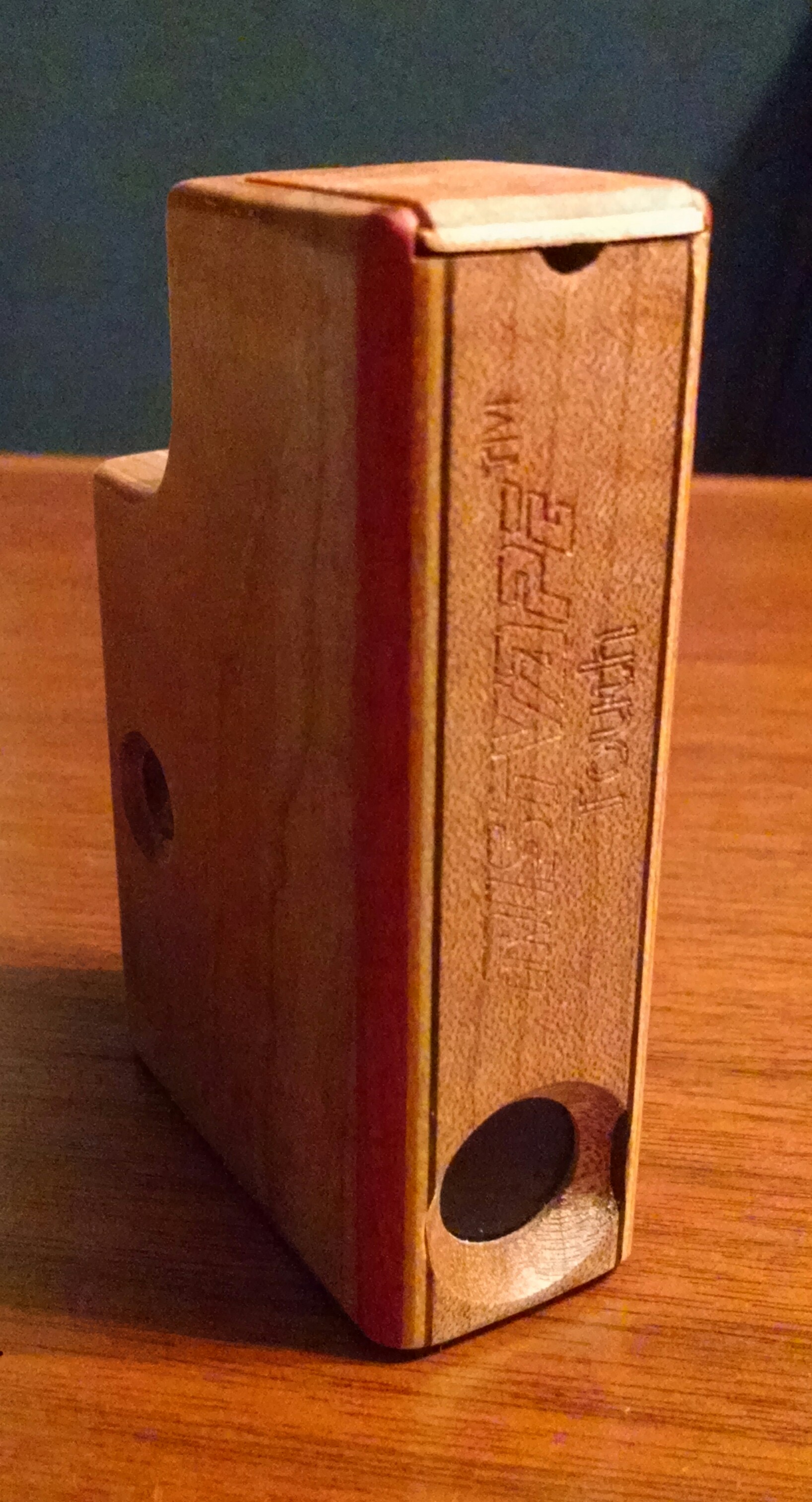

What I had in mind would be something like in the Project "Pure" with the screen domed the other direction, that is towards the heater. Here's a quick (and crappy sorry) pic:

The provided 14mm male tip just barely touches it and the entire screen is sitting below the bottom rim of the female. So if it was facing upwards like yours, the stem would push it down. And my concern is that it might happen with 3rd party water tools and adapters etc.

Note that the screen is held magically in place by friction alone, and like your design the main drawback is that you can dislodge it... which happened yesterday night! I had one finger inside trying to remove a small plant bit and the gf inadvertently pushed my elbow...

It was a real PITA to put back in place despite having access easily to both sides (which I assume won't be a possibility in the MVT?) I managed to put it back but it's not as flawless looking as when I first got it.

To solve this problem, Ryan in the Mi and Zi cuts the female GonG just below said rim, then sandwiches the screen between the GonG and a glass tube which also acts as a heater cover. The fit is super tight, I imagine he has quite some breakage rate when assembling those, especially since cutting the GonG right there kinda weakens it... I'm not saying this is the ideal solution, just stating what he chose in the end.

Another idea would be to cut some shallow slits just below the rim, maybe two would suffice? And have the screen lock into these grooves maybe. But you need to have real steady hands with the dremel, so easier said than done!

This wouldn't prevent dislodging altogether but at least it could make the re-positioning easier?

PS: the Project screen is just a mesh circle, it's not even folded like yours, just slightly domed. It's not clear from the crappy picture...

Last edited: