-

SCAM WARNING! See how this scam works in Classifieds.

-

The Frolic by Limelight Giveaway is over. Congratulations to the winner: Numerous_Nothing!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Glass on Glass = Unhealthy?

- Thread starter luchiano

- Start date

Andreaerdna

If God is the answer, then the question is wrong

I am using a Ti nail quite a lot (as a Ti-on-glass adapter on my VC) and I noticed that female glass joint grinded some Ti dust from male adapter

I googled it and I got redirected to this old cold thread, back on FC

YouTube content is gone and maybe this is for the best but it is clear, for the respect that is due to basic physics laws, that because gong isn't polished and it is hard : it is sanding each time you put in - pull out!

This day forward I am putting some grinder lube inside female of my bubblers every time after washing and adopt some extra care.

Lube will trap any fucking dust is created by friction and everything will be dumped during next wash.

I invite everybody, and above all folks using water tools dry , or direct draw vaporizers with gong connection

, or direct draw vaporizers with gong connection  , to put some lube in their female gong, she will thank you

, to put some lube in their female gong, she will thank you

(I mean your life)

I googled it and I got redirected to this old cold thread, back on FC

YouTube content is gone and maybe this is for the best but it is clear, for the respect that is due to basic physics laws, that because gong isn't polished and it is hard : it is sanding each time you put in - pull out!

This day forward I am putting some grinder lube inside female of my bubblers every time after washing and adopt some extra care.

Lube will trap any fucking dust is created by friction and everything will be dumped during next wash.

I invite everybody, and above all folks using water tools dry

, or direct draw vaporizers with gong connection

, or direct draw vaporizers with gong connection  , to put some lube in their female gong, she will thank you

, to put some lube in their female gong, she will thank you

(I mean your life)

debaserrrrr

Well-Known Member

Glad I stumbled on this thread!

Thanks for bumping it.

I guess I will start lubing my 'joints' with coconut oil.

Thanks for bumping it.

I guess I will start lubing my 'joints' with coconut oil.

djurodjakovic

Well-Known Member

I'm def worried now.

I never greased connections before. Now I use coconut oil on male/female connections.

never using dry glass pieces again (like the short one that you get as basic package for EVO).

I never greased connections before. Now I use coconut oil on male/female connections.

never using dry glass pieces again (like the short one that you get as basic package for EVO).

I don't think the dude in the vid is 100% wrong. Rubbing dry ceramics together can cause damage. I do think the dude in the vid is overstating what can happen and ignoring how to prevent it or remove it. Like folks have said: grease it and use water conditioning.

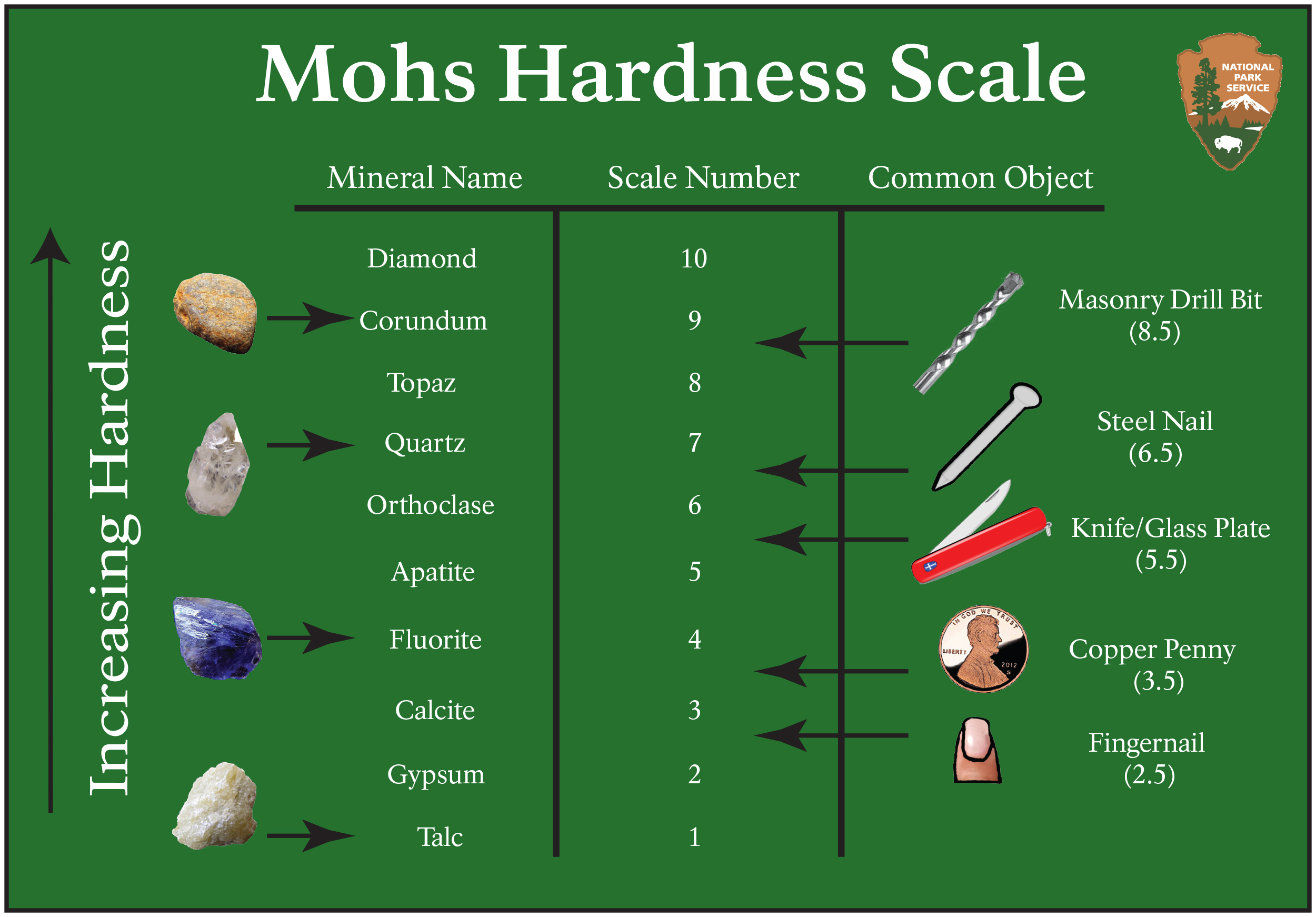

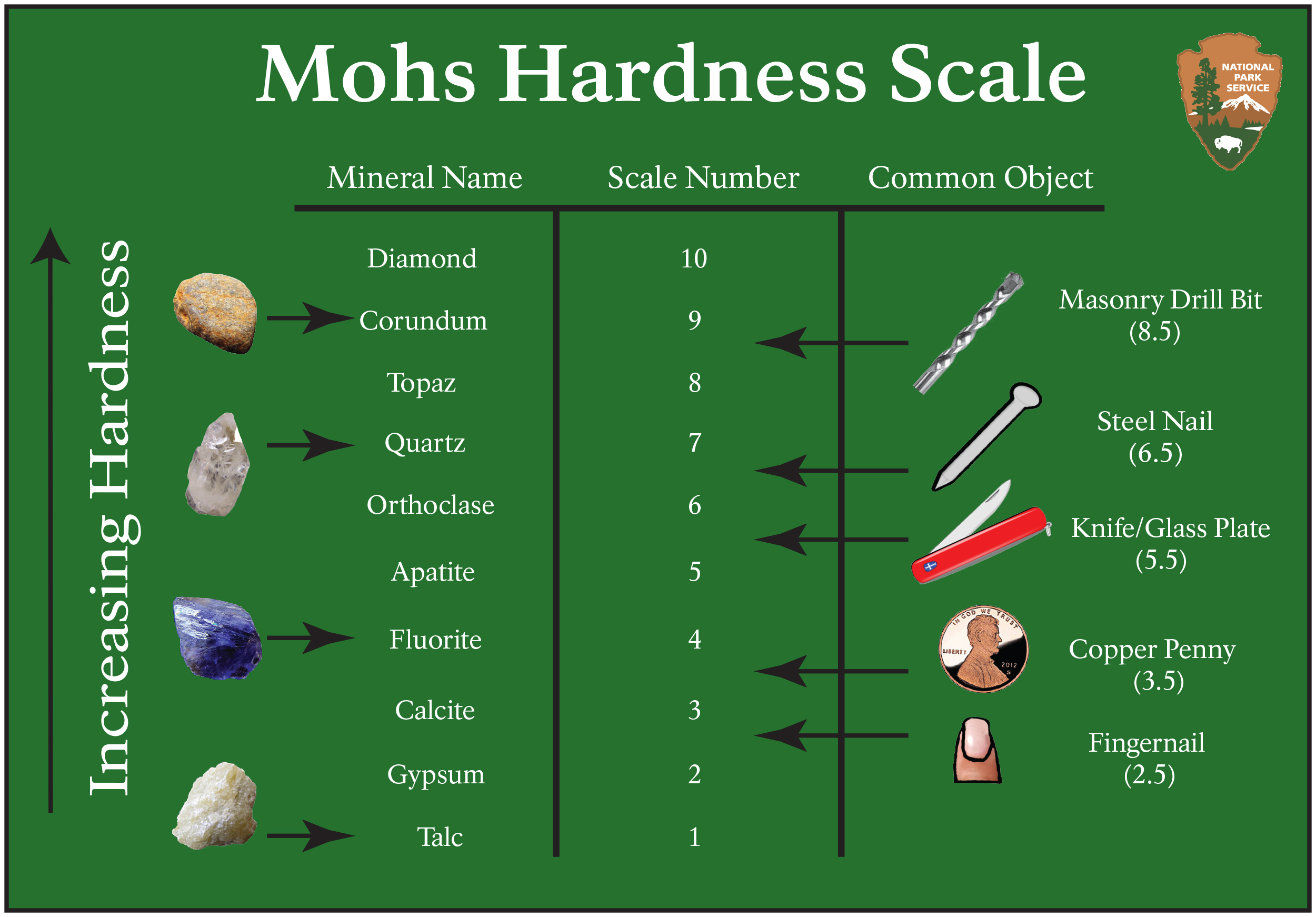

Just to frame things a bit: Boro is as hard as a knife:

Some boro is even a 7 on that scale. Hardened steel would be 7.5 Mohs.

One reason science and industry use boro is because of its hardness and scratch resistance.

I did a bit of googling and could not find anything talking about glass dust and joints. I could not find much that is public either as far as boro papers. I did find a study on glass and scratching in different humidities. It gets close to what I was looking for ...they rubbed a boro bead against a boro plate 400 times. Ya need an electron microscope to see what mushed with a dry pass.

https://www.researchgate.net/public..._Soda_Lime_Silica_Glass_in_Humid_Environments

Just to frame things a bit: Boro is as hard as a knife:

Some boro is even a 7 on that scale. Hardened steel would be 7.5 Mohs.

One reason science and industry use boro is because of its hardness and scratch resistance.

I did a bit of googling and could not find anything talking about glass dust and joints. I could not find much that is public either as far as boro papers. I did find a study on glass and scratching in different humidities. It gets close to what I was looking for ...they rubbed a boro bead against a boro plate 400 times. Ya need an electron microscope to see what mushed with a dry pass.

https://www.researchgate.net/public..._Soda_Lime_Silica_Glass_in_Humid_Environments

Under dry conditions, all of glass surfaces were damaged due to purely mechanical scratching effects.

glass surfaces could be protected from damage and wear through lubrication

Last edited:

DenverNugs

Well-Known Member

Ugh. This is probably the last thread on this forum that should have been bumped. Goodstash is a clown. Anytime someone calls him out on his bullshit he starts shouting that they're a pedophile. If you want a laugh, go look at his "Sex change" bong line. It has two grommet downstems so you can hit it "dry or wet".

He started going on about this bullshit when GonG waterpipes started to become the standard because of their superiority to rubber grommet bongs. Of course he's going to try to protect his shitty interests.

Think about it like this. Even if glass on glass joints did cause glass dust to come out over time, where would you be drawing that dust into? The water in your piece. I really don't see tiny glass particles doing anything other than floating around in your bong water until you empty it out.

If you're really worried, buy some joint wax. Just don't ever give money to this douchebag.

Ask yourself.. Why would he disable youtube comments and ratings on every one of his videos? He can't defend his arguments without shouting obscenities at people. All he can do is sling shitty glass on Venice Beach to people who unfortunately don't know any better.

He started going on about this bullshit when GonG waterpipes started to become the standard because of their superiority to rubber grommet bongs. Of course he's going to try to protect his shitty interests.

Think about it like this. Even if glass on glass joints did cause glass dust to come out over time, where would you be drawing that dust into? The water in your piece. I really don't see tiny glass particles doing anything other than floating around in your bong water until you empty it out.

If you're really worried, buy some joint wax. Just don't ever give money to this douchebag.

Ask yourself.. Why would he disable youtube comments and ratings on every one of his videos? He can't defend his arguments without shouting obscenities at people. All he can do is sling shitty glass on Venice Beach to people who unfortunately don't know any better.

MoltenTiger

Well-Known Member

Interesting topic.

Was this guy selling food-safe platinum cured silicone o-rings in competition to GonGs?

I'd bet his black rubber gasket rubbish poses more risk.

Labs grease their glass joints so they don't stick.

Joints that are dry and stick will produce negligible dust, but more importantly are frustrating and can take some serious time and effort to dislodge, plus they can break easily if they're fixed together well - ruining the procedure. Lubing joints is risk aversion but not because of dust.

I've never greased up my vape GonGs and I don't plan on it, they aren't ever a hassle to deal with dry so there's no point.

Was this guy selling food-safe platinum cured silicone o-rings in competition to GonGs?

I'd bet his black rubber gasket rubbish poses more risk.

Labs grease their glass joints so they don't stick.

Joints that are dry and stick will produce negligible dust, but more importantly are frustrating and can take some serious time and effort to dislodge, plus they can break easily if they're fixed together well - ruining the procedure. Lubing joints is risk aversion but not because of dust.

I've never greased up my vape GonGs and I don't plan on it, they aren't ever a hassle to deal with dry so there's no point.

throwawaytre3s

Well-Known Member

Interesting topic.

Was this guy selling food-safe platinum cured silicone o-rings in competition to GonGs?

I'd bet his black rubber gasket rubbish poses more risk.

Labs grease their glass joints so they don't stick.

Joints that are dry and stick will produce negligible dust, but more importantly are frustrating and can take some serious time and effort to dislodge, plus they can break easily if they're fixed together well - ruining the procedure. Lubing joints is risk aversion but not because of dust.

I've never greased up my vape GonGs and I don't plan on it, they aren't ever a hassle to deal with dry so there's no point.

My immediate thought was that that glass joints wouldn't be so widespread within the scientific community if it weren't pretty much reliable and safe. The last thing you want is unknown particulate getting into any of your solutions, so using glassware that produces dust on moderate use seems silly to me, given that that labware probably sees 100x more use than many of our own pieces do.

MoltenTiger

Well-Known Member

When we were taught proper Quickfit (common brand of GonG manufacturer) glass joint practice at school, dust or silica contaminants were never brought up, only that if you're setting up a complex apparatus, where the joints get hot or might jam for another reason, you use grease to prevent destroying the apparatus and spilling whatever's in it.My immediate thought was that that glass joints wouldn't be so widespread within the scientific community if it weren't pretty much reliable and safe. The last thing you want is unknown particulate getting into any of your solutions, so using glassware that produces dust on moderate use seems silly to me, given that that labware probably sees 100x more use than many of our own pieces do.

I can appreciate that some grinding and atom dislodging occurs when dry joints are forcibly twisted whilst remaining in contact, but you'd really have to go out of your way before producing any sort of problem by doing that. I think it's nonsense, people put soda lime glasses stacked against each other in dishwashers. That topic is as relevant, no one should be thinking about it unless they're selling some bullshit silicone device that is unnecessary

KeroZen

Chronic vapaholic

Even if glass on glass joints did cause glass dust to come out over time, where would you be drawing that dust into? The water in your piece. I really don't see tiny glass particles doing anything other than floating around in your bong water until you empty it out.

I use all my vapes dry, there's no water to catch anything.

My immediate thought was that that glass joints wouldn't be so widespread within the scientific community if it weren't pretty much reliable and safe. The last thing you want is unknown particulate getting into any of your solutions, so using glassware that produces dust on moderate use seems silly to me, given that that labware probably sees 100x more use than many of our own pieces do.

But they lube their joints when most people here don't.

I think it's nonsense, people put soda lime glasses stacked against each other in dishwashers.

You can't compare polished glass with ground glass, the latter is rough and begging to scratch against anything.

-

I raised the concern in the Milaana thread with some stem I was testing. With my technique and load size I need about 30-40 hits to complete a bowl, let's say 40 for simplicity sake. With the hotspot issue I've been having since I damaged my unit, I need to rotate the stem every two hits, so that's 20 removals+insertions per bowl.

If I use the Milaana as a daily driver I can easily do over 8 bowls per day, that's already 160, meaning in only 2 and a half day I've done the same 400 removals+insertions as in the test above.

So yes I think it's a valid concern and I'll be greasing my joints from now on.

MoltenTiger

Well-Known Member

I didn't mean to compare the different contact surfaces, but rather the innately harmless nature of doing either thing. However,You can't compare polished glass with ground glass, the latter is rough and begging to scratch against anything.

If you're usage warrants it, than extra steps to avoid potential risk are a great idea. Personally there's too much surface area between my ground joints and a mouthpiece for me to be concerned, but everyone's set up is different. Additionally, I've never discovered any glass fragments or dust, and I collect and handle adhesive translucent golden goop right from China glass ground joints (elbow adapters). I will say they're not the worst quality I've seen, but they're noticeably inferior to proper schott glass. Nonetheless, I've never observed any glass contaminants, so I have nothing to fear.in only 2 and a half day I've done the same 400 removals+insertions as in the test above

Even with 400 adjustments I would be surprised to see anything concerning, but it does depend on the quality of the joint at the end of the day

If they're sticking and squeeking and you're turning them frequently, a bit of beeswax might actually be worthwhile for multiple reasons.

Andreaerdna

If God is the answer, then the question is wrong

Some between us are more cautious/concerned than others, no reason to make jokes out of theirs/ours concerns

If for you glass dust is not an issue at all than explain us the reason why , rather than saying there are "other" risks in life or "everything in life is dangerous" , or simply walk your way to somewhere you have something relevant to say

Also glass dust is very little and very few to be appreciated by simple eye noticing, nonetheless it is produced so often that for me and some others it is a concern indeed

Edit @MoltenTiger For sure some dust sticks to male joint and I believe it get spreaded in the air around you when you lift up.. yet again very few, very little but very often.

No need to pay a freak or buy anything. If you have a lips lube/grease it will make it (i use my grinder grease)

If for you glass dust is not an issue at all than explain us the reason why , rather than saying there are "other" risks in life or "everything in life is dangerous" , or simply walk your way to somewhere you have something relevant to say

Also glass dust is very little and very few to be appreciated by simple eye noticing, nonetheless it is produced so often that for me and some others it is a concern indeed

Edit @MoltenTiger For sure some dust sticks to male joint and I believe it get spreaded in the air around you when you lift up.. yet again very few, very little but very often.

No need to pay a freak or buy anything. If you have a lips lube/grease it will make it (i use my grinder grease)

Last edited:

Be sure we are all talking about boro. You probably have the stuff to test glass in your kitchen. Boro refracts light close to canola/veggie/olive oil. Combine the two and ...

The ground joint should disappear.

@Andreaerdna do you get resin buildup on the joint at all? Is there a grit to it?

The paper talks about the particles that can come off from scratching. It also states that humidity can change the particle size and how they stick. Humidity also changes how the glass scratches. 20-40% RH is best...things glob up and fall off less at that range. Only 0 RH is mechanical. Above 0 the water in the air changes what happens. It is really worse the higher you go up. More stuff fell off at higher humidities in the study. All of this has to do with dry glass though.

The joint should not look frosty if it is lubed right. Maybe we need a lube your joints thread?

The ground joint should disappear.

@Andreaerdna do you get resin buildup on the joint at all? Is there a grit to it?

The paper talks about the particles that can come off from scratching. It also states that humidity can change the particle size and how they stick. Humidity also changes how the glass scratches. 20-40% RH is best...things glob up and fall off less at that range. Only 0 RH is mechanical. Above 0 the water in the air changes what happens. It is really worse the higher you go up. More stuff fell off at higher humidities in the study. All of this has to do with dry glass though.

the mechanochemical

wear of borosilicate glass increases as RH increases. In the

case of soda lime silica glass, the mechanochemical wear

decreased with increasing humidity.

Research paper: Mechanochemical Wear of Soda Lime Silica Glass in Humid Environments. Available from: https://www.researchgate.net/public..._Soda_Lime_Silica_Glass_in_Humid_Environments [accessed May 7, 2017].

Yeah! I use stuff for lips.No need to pay a freak or buy anything. If you have a lips lube/grease it will make it (i use my grinder grease)

The joint should not look frosty if it is lubed right. Maybe we need a lube your joints thread?

Last edited:

KayJay

Well-Known Member

Ok my take on this is BS! yea ground glass dust might not be good if your snorting it but the amount suspended dust we breath in as humans on a daily basis is crazy, if there was any truth to this beach front property would be cheap as nobody would want to live there in fear of silica dust. Just keep this in mind next time you drive in peak hour stop start traffic, How much carbon monoxide, brake dust, clutch dust, exhaust soot, unburnt fuel, catalytic converter byproducts, NoX's and crap are you breathing in? last thing id be worried about is the .00001 of a gram of glass that might come off my cone every time I move a joint.

Andreaerdna

If God is the answer, then the question is wrong

@jojo monkey cool information on light refraction of boro glass, have to try one day

No rosin or build up on male joint (or female), both have grit (gound surfaces) so I assume that dust get sticked to both surfaces by mechanical mean, not sticked like glued but rather griped (?) and any little vibration could free it

I never noticed any dust and I clean quite often. Only thing I noticed with my eyes is the black dust created by Ti on glass adapter I was using.

No rosin or build up on male joint (or female), both have grit (gound surfaces) so I assume that dust get sticked to both surfaces by mechanical mean, not sticked like glued but rather griped (?) and any little vibration could free it

I never noticed any dust and I clean quite often. Only thing I noticed with my eyes is the black dust created by Ti on glass adapter I was using.

Andreaerdna

If God is the answer, then the question is wrong

TBH lips grease works nice trapping glass dust but it is not very clean (my enano gongs collect a lot of shit because of stickyness)

I am using now a 18mm bubbler with a 14mm gong wrapped with enano silicon sleeve, it fits securely and no more shit stickyness (little plus: silicon sleeve gives it a little protection, even if weak/random, when it falls)

I am using now a 18mm bubbler with a 14mm gong wrapped with enano silicon sleeve, it fits securely and no more shit stickyness (little plus: silicon sleeve gives it a little protection, even if weak/random, when it falls)