Alright then; My review will tell you how to get into your FlowerMate CAP vaporizer. And how not to

First of all, I did not receive my DHL notification. However, Flowermate was fully on top of getting mep the test unit. I was PM'd by

@FLOWERMATE OFFICIAL to know if I was interested. I was very clear that I would be disassembling the unit to share the gruesome details of their insides. And I also told 'The Official' that people love this so don't make me eat my words

First image I give you Packaging Origami! What we've all come to expect when you have nothing more to present. But that certainly isn't the case here. Every crevice has a prize

So for my first image, PRO: Nice BoxWorx

This next part is moot to show but it does add context. Thank you for those that have already shown the investment obviously found important enough to include two very nice ceramic pieces. These are molded and fired ceramics but the fact that they are included shows a nice degree of fit and finish. Everyone wants to extend that path length. And with good reason. I am not sure I am quite as appreciative of the cavity that generates a vacuum, however. Between the actual tip and the dress-face of the housing, some general bio-sharing will happened. And it is an area one should know to clean on a regular basis. I'd suggest not sharing the unit without this understanding.

As to the smell that has already been referred to; yea. What can I say, I won't draw from it. I heated it up and it stopped me dead in my tracks. No worries; all but gain for this thread. I am obviously going to give FlowerMate the benefit of the doubt that this formulation of silicon is safe for the intended use-case well into the 420F range. After all, they have a whole lot of devices under their belts.

To be fair I asked my wife to smell just the flexible piece. She couldn't smell anything. Then I put it together and ran it dry to 420F. Ripped the cap off and let her smell that. That was an immediate rejection. Then a whiff of the chamber also got that really "why did you do that to me?" vibe. We're not even to inhaling stuff from it yet, just sniffing! What's worse in my view is that it smelled an awful lot like Buna-N... basic ordinary o-ring material. I don't know that silicon has that same odor normally. I only mention this in that I cannot answer if this scent is something that will off-gas in time, can be baked out in the factory, or if this is a normal off-gassing rate. I hope it is just part of a break-in. Others will weigh that to death.

So here is the very boring image of the stinky black piece that holds the hard-parts together;

For my second image; CON - It stinks when heated. Fine at room temperature.

For my third trick, all hail destructive testing

Just so you know, I did not do what I am going to prescribe. Know I went in through the top to get here...

If you want to open this thing up, it will fight you. The top is a snap-fit that has a super hold. Once they are together, the latches don't want to give up their hold. ...it gave up for me.

BUT THIS COMES WITH A WARNING!

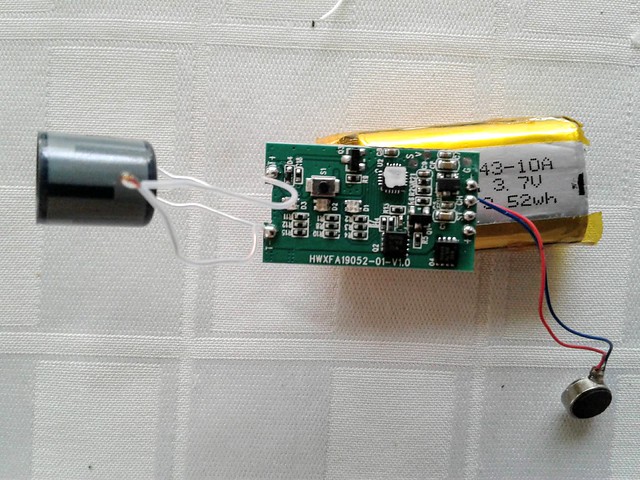

There are two skinny little wires that, once crossed, are like an open light bulb. The cell inside is a 10A LiPo that will blaze all 0.95 amp/hours of power in short order. I got lucky the first time, but I did cross them. A lot of smoke and the LEDS lit up bright white. And spoiler; the circuit is still working at the time of this writing.

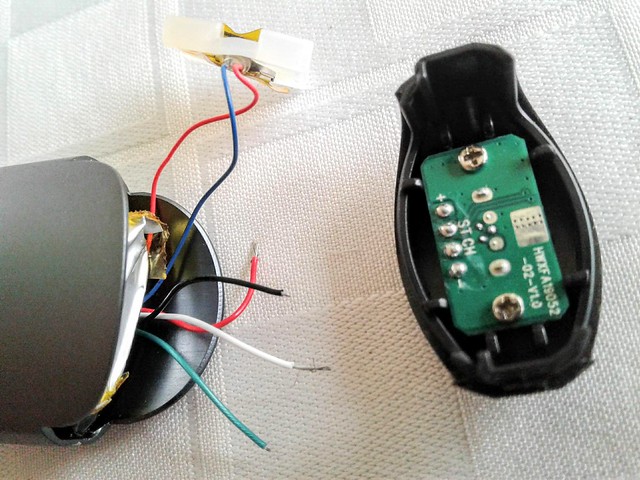

To get inside, this bottom cap can be removed with a narrow faced screwdriver and a simple twist in the groove between the plastic and the metal. Go in at the sides if the power button is the front. Remove the board while still attached to the wires. It will go out the other end with the rest of the guts. You might take note of how the vibrator (white thingy) is situated. Again, I started from the other end.

Image No. 3 ; PRO - The dress, fit, and finish of the USB and bottom cap is nice. These two screws are the same as the others in the unit. The fit is a simple snap-fit. Recesses are coined in the case. Both the case and plastics are as good as it gets.

Note how the red and black wires are pristine in the previous image

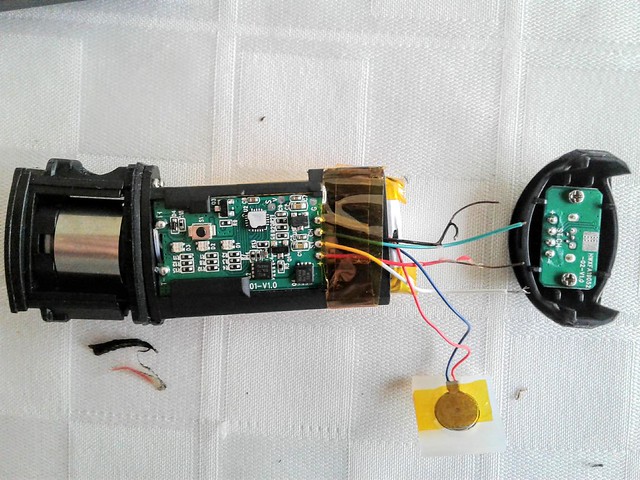

On to image 4 where I finally wrestled the guts from the case. The top of the case has 4 serious indents that the plastic snaps into. It took deformation to pop those loose. I'm sure there is a trick but with a re-insertion, I didn't get it. If I figure out a way to pop the business end off, I'll post an addendum.

You've been warned of hazardous energy levels. I was able to handle this well enough but you are in technician territory now. The unit does have a distinctive chamber for the air path and the intakes are filters with a course stainless steel screen. There is a silicone seal between the heating chamber and the electronics chamber that would only allow minimal environmental sharing. It would qualify the environmental seal as a recognizable NEMA rating, but that just says dust doesn't want to get in, but could. It is well thought out in most respects. Anything I could add are niggles with regard to shielding electronics from the vape path.

There are a series of screws that connect the upper plastic frame to the lower circuit carrying frame. This clamps a silicon rubber seal. It might be wise to loosen those screws from the bottom when you've removed the bottom cap.

Image 4 deserves a PRO on general layout and vape-path considerations with regard to electronics and cells.

Now for the meat of the unit. No fake meat here. This is tech at its.. wait.. Oldest? And Newest joined in a cool technique.

The bowl is not stainless steel. Put a magnet on it. It is iron. Better explained, it is the old glazed cookware you probably have in your cupboards. What is unique is the conductive paint they use to create a heater on the cylindrical surface. It's a technique used in industry for conductive paths on ceramics for decades but a controlled heating element on a cylinder, that gets kudos. Also note the tiny thermister and the solder joints on the bowl. They were nice and clean solder joints as well.

What didn't get my kudos is the pile of tape and cotton. The tape is not particularly sticky. It has the consistency of taffy. One layer is applied over the solder joints. A second layer attaches the thermister slightly above and between the solder joints. A dense wrapping of cotton (presumably) followed terminated with two layers of this same tape. This whole lot is again insulated with a stainless steel ring and the stainless steel air vents. This heater-insulation layer is in the incoming air path. I see no means for particulate generation from any of this unless this tape gets brittle over time. The cotton is well encased in the tape.

Again, I have to give benefit of the doubt to FlowerMate. This mushy tape must be a qualified material to wrap around a metal heater capable of functioning to 420 degrees F plus margin. Am I comfortable with this arrangement personally? Not in the least! Am I impressed by the engineering? Oh yea!

The only other note I will ad is the other materials in contact with the chamber; the upper clear silicon seal is in direct contact as is the plastic piece that the chamber sits on. Likely well rated for the temperatures but not in my vape.

Image No. 5; CON - Too many unverifiable unknowns with regard to material.

And for a quick note: this is the battery they use. Nice little power plant. 3 of these and you could power your portable IH for your VC.

Picture #6 - PRO - Serious dedication to providing power. This is easily equivalent in storage to a any 18650 with a pretty good drain rating.

Although I've completely maimed this poor device, the core of the unit is still functional. Charging is a bit tougher but you get my drift. If you do power it up in this state, be sure to have the thermister close to the bowl or it won't get an up-to-temp signal and possibly run-away on you.

This did get me to a start thinking of what happens if there is a fault? What if the thermister went bad? What would the unit off-gas in a single fault condition if the temps went nuts? What is the backup protection? I don't know how their assessment answered that question.

Image No. 7 - PRO - Robust modular build with quality components at its core. This is a cohesive design team that learns from every design. Their dedicated effort is certainly reflected in this product.

(10,000 character limit reached

)