Hello

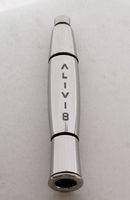

This is Dan From vaporgenie. A customer alerted us to this thread. After reading it, I thought it would be a good idea to respond to comments made by EYE1DER, the Alivi8 manufacturer, and explain a few things about this product. We have purchased, used and inspected the Alivi8, and have some important things to say about it.

EYE1DER made the claim that "it functions similar to vaporgenie in so much it uses a lighter but the similarities end there..." This is false and misleading. The Alivi8 Functions EXACTLY like the VaporGenie, and in fact it violates our US patent (US Patent 7,434,584), and the patents we have in other countries. We do not have a patent in the UK so they are free to make and sell the Alivi8 in the UK. Like the VaporGenie vaporizing pipes, the Alivi8 uses a filter between the flame and herbs in a manner designed to mix flame exhaust and ambient air. Consequently, the Alivi8 infringes our US patent. You can read the patent for details.

However, there are several differences in design and performance between the Alivi8 and the VaporGenie. The most important difference is that the Alivi8 uses a METAL foam filter instead of a CERAMIC filter. The filter in the Alivi8 is made of "FeCrAlY" alloy, an alloy of iron, chromium, aluminum and (optionally) Yttrium. This is a commercially available metal alloy used in industrial applications requiring high heat resistance. In our opinion, FeCrAlY alloy is poor choice for the flame filter, because, despite its temperature resistance, it DOES oxidize and release metal fumes This is particularly a problem with torch lighters, which burn hotter. But even with a candle butane flame, the FeCrAlY filter discolors, indicating oxidation. Typically, maximum use temperatures for FeCrAlY alloys are in the range of about 1100-1350C. At or above these temperatures, FeCrAlY alloys oxidize and produce metal fumes. I have personally heated FeCrAlY materials to these temperatures and observed the fumes and oxidation. The FeCrAlY changes color and texture. Butane flames can produce temperatures up to about 1300C maximum. So, it is clear that FeCrAlY flame filters can oxidize and produce metal fumes if used with butane flames. By comparison, the silicon carbide used in VaporGenie pipes is guaranteed not to oxidize up to about 1650C, a temperature that cannot be reached by butane flames. And even if it does oxidize slightly, the silicon oxide produced is adherent (so its not inhaled) and nontoxic and the carbon dioxide produced is nontoxic. Silicon carbide does not contain metals and therefore will not produce metal fumes no matter what the temperature. Silicon carbide is clearly the better choice.

When I was originally developing the VaporGenie pipe back in 2002 and 2003, I experimented with FeCrAlY and similar materials. I observed metal fumes and oxidation. Consequently, I decided not to use FeCrAlY-type alloys in the VaporGenie.

Also, FeCrAlY foams are very soft and fragile. They are more easily damaged than the silicon carbide filters used in the VaporGenie.

One significant design problem with the Alivi8 device is that the FeCrAlY filter is very close to the flame input end of the pipe. It is only recessed about 1/4 inch. Consequently, it is difficult to keep the flame off the filter. Soot deposition is the result. And if soot is deposited on the FeCrAlY filter, burning it off with a propane torch will cause severe oxidation of the FeCrAlY. FeCrAlY is simply not designed for exposure to the high temperatures required for soot removal. By comparison, all vaporgenie pipes have deeply recessed filters so that its easy to avoid touching the flame to the ceramic filter. The newly redesigned classic VG pipes have filters recessed by about 1 full inch (and are removable for cleaning). Soot is easily burned off silicon carbide without harming the filter.

The Alivi8 marketing materials claim that the pipe is made of "the finest medical grade stainless steel". This is a strange claim. For use in a smoking pipe, there is no functional difference between the different alloys of stainless steel, except for possibly 316, which has exceptional corrosion resistance and is very expensive. But alloys 304, 303 and 302 (all very similar or sometimes even identical due to overlapping composition tolerances) can also be used in medical applications, so these are all "medical grade". We use 302 stainless in our SS coil pipes and wireforms, 303 stainless in our stainless bats and 316 for our screens. But we dont mislead our customers and hype our products with meaningless claims of using "finest medical grade" stainless steel. Nowhere does Alivi8 specify which stainless steel alloy they are using. So perhaps they can explain what, exactly, they mean by "the finest medical grade stainless steel"? If they are using 316 (or some other exotic alloy) they deserve credit, if they are not, they are jerking people around and being misleading. Alloys 302, 303 and 304 are all regular, plain-old "medical grade" stainless steel.

Another issue we noticed with the Alivi8 is that the screen placement creates problems. There are two places to put the screen. The upper location causes the screen to fall out when the bowl is dumped. The other, lower location positions the screen directly on top of the bowl flow hole, causing it to block airflow through the pipe. It is unclear to us where the screen is supposed to be, since both locations are problematic. The Alivi8 came to us with the screen in the upper position, where it falls out all the time. This issue is easily remedied with a wireform for holding the screen in place.

Alivi8 emphasizes the importance of the serpentine-path for cooling vapors. At VaporGenie, we have experimented with such cooling features but decided that they create more problems than they solve. Specifically, cooling the vapor makes it difficult for a user to monitor the temperature in the pipe because the temperature of the inhaled air is not an indication of the temperature applied to your herbs. We found that users could control the pipe temperature most effectively if there is rapid temperature feedback to the user. Without this temperature feedback (i.e. with a cooling mechanism), users are unaware of the temperature in the bowl, and they wind up overheating and burning. If some people prefer having a vapor cooling mechanism , please let us know and we will be happy to design a product with a cooling feature. But be careful what you ask for, because a cooling feature will make the temperature more difficult to monitor and control.

A the risk of appearing too sensitive, I'd like to criticize the makers of the Alivi8 for copying our marketing materials and writing. The language they use is sometimes nearly identical to what we wrote about the VaporGenie. Here are some examples:

"many years of satisfying vaporization"

"When used properly the Alivi8 produces very little tar"

"If you inhale smoke then the temperature is too high"

The folks at Alivi8 were apparently unable to write an original description of their product on their own. They copied our product AND our writing.

I hope this helps people understand more about whats going on with the Alivi8.

If anyone has questions or comments please feel free to ask. or you can email me directly (and privately) at info<AT>vaporgenie.com

dan

(I haven't used pipe-like vaporizer before).

(I haven't used pipe-like vaporizer before).