still with me? the co2 tank odyssey continues. There is success at the end of this post, I promise

So at this point, I gained some satisfaction knowing the ceramic donut as a TC-capable heater can work in my tank, at least in theory. But the wick was my issue, at this point.

I recall reading either in this thread here, elsewhere in this forum, or another forum in my searching?

about the

readyXwick ceramic fiber wicks for RDA or RTA coil wicks. I did as much research as web searching could dig up, most of the sources from forums and readyX themselves. Apparently, baking the ceramic fibers in a kiln at very high heat for a long period makes this material safe and high-performing for wicking, supposedly, whereas NOT heat-curing them in this manner makes them

very unhealthy as a material for vape wicks, somehow?

(supposedly, the other commercial use for readyxwick is to insulate wires in cruise missiles

(supposedly, the other commercial use for readyxwick is to insulate wires in cruise missiles  demanding specs

demanding specs)

Maybe one of you guys is smart and can explain it to me, why these wicks are/aren't safe for vape wicks, because

@fernand is still not sold on this concept, but good news still:

the readyxwick worked for me in my coils

I took the RBA coil out (sticky fingers yet again) and removed the swollen cotton wad

sigh...what a waste..probably 400mg of 70% thc oil stuck in there. not a total waste though. I will vape this wad on my arizer EQ or maybe one of my new DT 3.0 donuts

I like how the donut had no char or burned marks on it even though my repeated, high-temp tests to coax vape out of it, with the crappy cotton wad. Good job, temp control.

I then replaced it with a neat loop of the ceramic fiber, sitting right on top of the donut, (no pic for this part) coil back in again, swish, let the wick get wet, wait, repeat....

SUCCESS! ! ! finally

At 420-430F, 25w, TCR 245, I was now getting nice, tasty, smooth clouds of the CO2 oil,

and no irritating sensation to go with the vape! I can take repeated hits on this tank, back to back, and at worst, it just makes my throat feel a little hot. And it does leave a slight sticky co2 residue on your lips and front teeth and mouthpiece, with repeated use. I can live with that, any tank will do that. The

gurgling and spitting and clogging is hardly an issue with this build. The vaporessos had issues with all three, but now with the donut and readyxwick, I sometimes just get a comforting, quiet bubbling noise as the donut reaches full heat and is drawn on to make vape.

So this was all very nice at this point, but compared to my old setup, my vape production was

still considerably less. Quality-wise, vapor is

very very close to the excellent, tasty smooth (oil-leak inducing) coils from vaporesso. But I want

MOAR of it

haha...

om-nom-nom gimme bigger vape haha

From a 10-sec puff of my new coil, this felt equal to a 4-6 sec puff on the vaporesso coils. I have 3 tanks planned in this project for 3 different strains and oil types, so I made immediate plans for the next coil head that I imagined from the beginning:

double donut coil ! ! !

double donut coil ! ! !  muahahaha...

muahahaha...

I figured I have space to stuff 2 donuts into the big cubis RBA casings. But having worked with the smaller cubis BF coil casings, I also found those coils can fit a 7mm donut with tiny space to spare. The top-feeding oil path of the CUBIS tanks and the thick top of the RBA coils left me with a tiny, thin crack to squeeze my oil through to the bottom, which made loading a time-consuming chore. The skinny BF coils gave me a lot more space in this gap, so I used this kind for my double-donut coil. I drilled

hella holes in this mofo for max-juice swishing, and I think these efforts paid off.

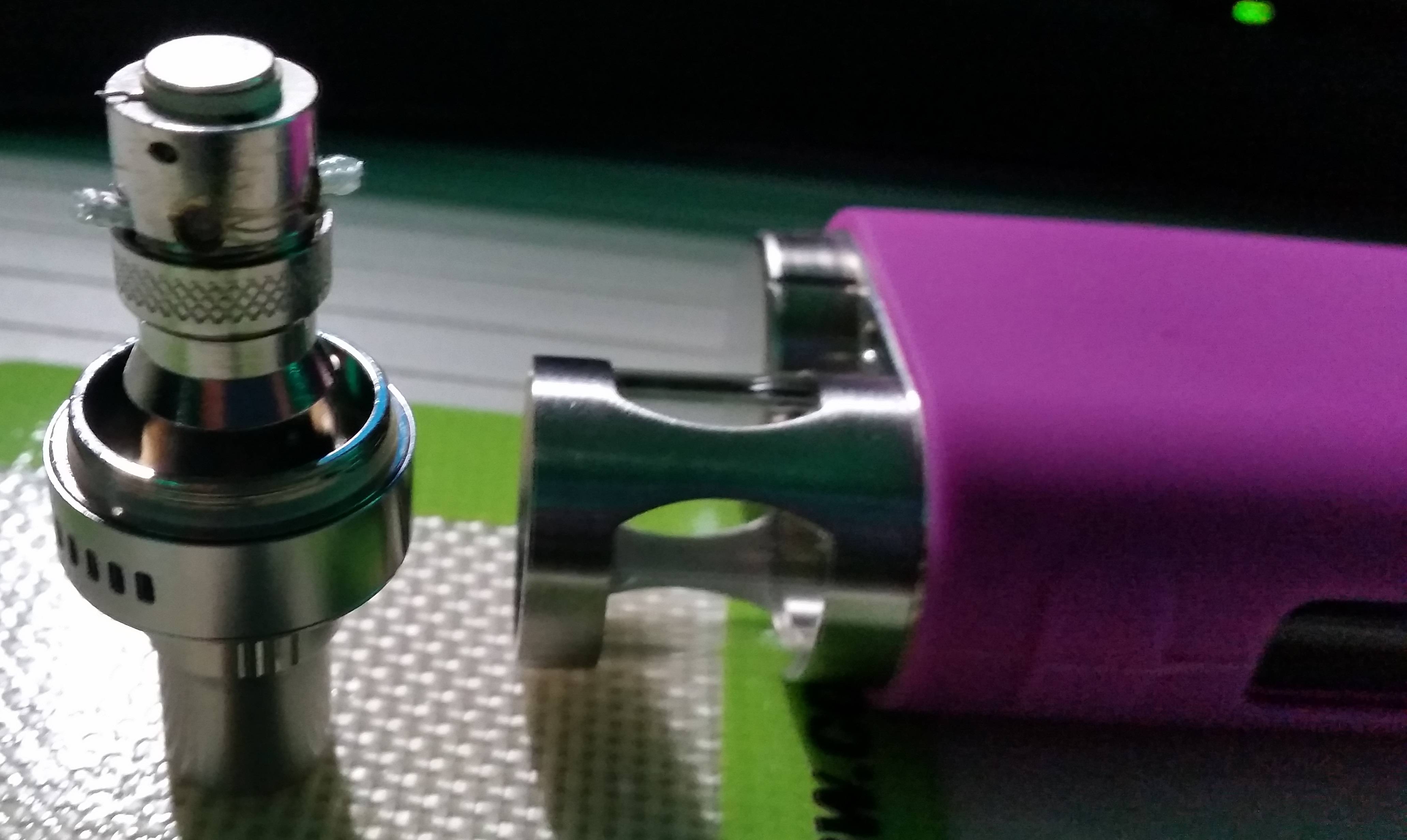

Its hard to see, but it's there, 2 donut discs almost parallel and flat and level with the bottom of the coil. It was a tight squeeze in there, to also route 2 pairs of wires to the right spots and get the 510 pin closed tight, and then slip some strands of readyxwick also. It took many attempts and tries getting "atomizer short" and "atomizer low, check atomizer, " etc. on an empty test tank to confirm continuity on my double donut coils.

At this point in the project, with the single donut coil sitting proudly to the side, I started with a new tank and fresh oil (gorilla glue 4 co2): in the time passed during this project, joyetech released new CUBIS pro MINI 2ml tanks that work with the same coils and same functions, just shorter and smaller unlike the big 4ml regular ones. The 4mls are overkill for a gram of oil, and the minis have less surface for oil to stick on and not get vaped, so the new double donut coil went into one of these.

here's a video of me test-firing the double coil @ 18W (on a spare, empty tank without the wicks)

near the end you can kind-of see both coils glowing red, and how they are not at all level and parallel to each other

Ohmed in @ 0.30, used TCR 245, 30w, and 390F is a sweet spot for the co2 oil. Patiently let the oil wick up, swish swish, after a few light hits...

wow

finally getting what I want!

BIG clouds....still smooth and tasty...no hint of burning or irritation. almost double sized clouds as my single donut coil! (duh!

) To fetch the cloud that I would need 10 seconds to get with the single disc coil, my new double donut coil only needs 5-6 second pulls to match that. 10 second clouds with the 2x donuts are amazing.

This made me so happy.....

In between many other vape projects, I got around to making a second double donut coil for another CUBIS pro MINI tank: this one eventually worked, but I got a bit over-enthusiastic with the wicking here.

I used this double donut coil to replace the single donut coil that was already working in the earlier tank. I tilted that tank to the side to let the oil collect to one side and try to avoid the new coil head dragging the existing oil or having that oil block the metal 510 pin on the bottom and block atomizer contact (i was having this problem alot)

The greedy, excessive wick sticking out was grabbed and dragged by the oil on the side, when it was screwed in. This pulled the wick out of its place in the coil and left it floating loose in the tank, not it's place or function. I had to remove the coil and re-wick it more modestly, without the readyX's sticking out, only tucked firmly in the coil. More wasted oil and sticky fingers again, and another re-fill, but the second double donut worked now

just about as well as the first....

rinse, repeat, happy with this formula for these coil builds. I've had at least one of these cubis tanks sitting on my desk full of oil for over 2 months now, and that oil isn't moving anywhere it shouldn't, so I'll proclaim these tanks

LEAK-FREE! at this point.

I think as long as they are not over-filled, or stored in a lying flat, sideways position, or stored in a very hot car, (probably with those earlier 2 conditions),

it will not leak. Just keep it standing up straight, don't do anything stupid, everything screwed in tight, no leaks!

After my earlier experience, I don't think I can ever trust a tank with bottom-mounted, bottom-air fed coils.

I went and made a third double donut coil for myself, so I got 3 of these running on 3 eleaf picos now

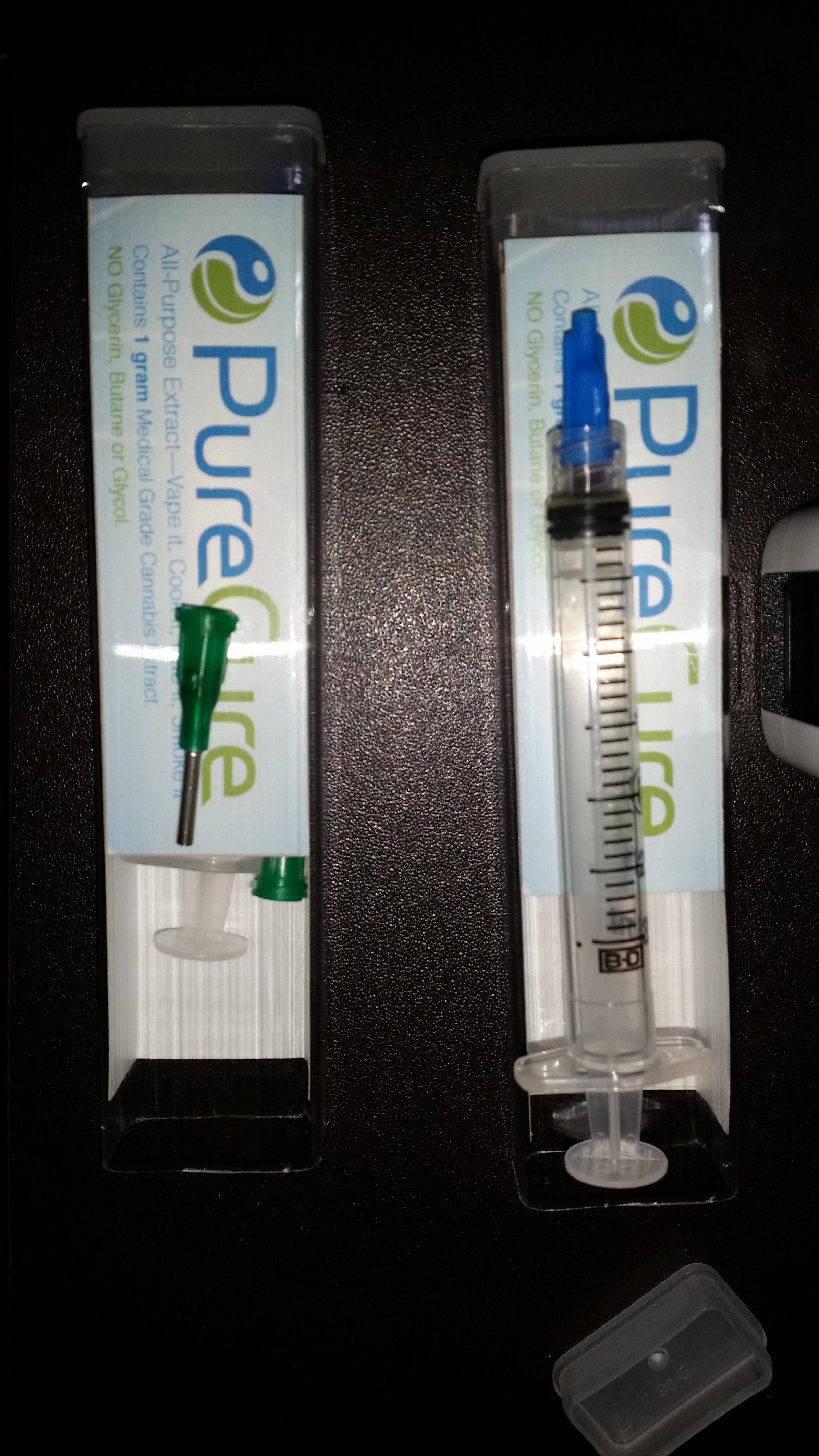

my latest, 3rd tank to get double-donutted: running "pure-cure" alcohol extracted, presumably artificially-terped' oil. This one is more flow-ey, less viscous than co2, but thicker than glycerin still. This guy needs to be set to make 430F instead of 390 for the big cloud, but it's still nice. This tank started the donut tank project with the cotton wick and larger RBA coil head before getting the final upgrade to double donut with readyX wick.

This pico and cubis pro mini got the double donut second. It's running some sour diesel co2 oil. This tank found success as the single donut coil + readyxwick at first, and was later upgraded to duals.

And this tank and coil here has the honor of being my first successful double donut build, with the gorilla glue 4 oil. started from a fresh coil and tank, not a refill or a multi-swapped out coil build project like the other 2.

So yes! That's where I'm at now. It's an idiot proof, perhaps-medical grade? vape that can deliver hundreds and hundreds of quality puffs on demand, until I need to recharge the cell, or refill the tank, and that's how I intend to use it. Click, puff, vape, be happy.

Thanks for reading all this, I am chronically incapable of making short posts, but something like this should be detailed. I hope this will be interesting and useful to some other people. And even though I'm quite satisfied with the co2 tank project as it stands, I'm always open to suggestions and more improvements....for the next coil build....

the ultimate heater for my goals would still be a cylinder shaped ceramic heater intended for RBAs with a Ni or SS wire...but until I could source that.... vape on my friends!

Not wanting to repeat almost certain failure, I scraped up and reclaimed all the fresh, leaked oil and reviewed my options on the interwebs....

Not wanting to repeat almost certain failure, I scraped up and reclaimed all the fresh, leaked oil and reviewed my options on the interwebs....

I found similar coils at many other chinese vendors, they either all were kanthal, or if they didn't say what metal, the customer service reps later replied they were kanthal, or didn't respond.

I found similar coils at many other chinese vendors, they either all were kanthal, or if they didn't say what metal, the customer service reps later replied they were kanthal, or didn't respond.  If any of you guys are aware of ceramic heaters like these for RBA's / drippers that do have TC-type wires like Ni, Ti, SS, etc, plz let me know!

If any of you guys are aware of ceramic heaters like these for RBA's / drippers that do have TC-type wires like Ni, Ti, SS, etc, plz let me know!

Even with the tank half full

Even with the tank half full

Because the vapor was pretty meager still, just a little vape on long, 10-sec pulls. Even worse, the puffs had an odd, irritating, sensation of my throat being coated with crap. Like on no vape I've ever used.

Because the vapor was pretty meager still, just a little vape on long, 10-sec pulls. Even worse, the puffs had an odd, irritating, sensation of my throat being coated with crap. Like on no vape I've ever used.  To remind u guys, I'm not a e-cig vaper, not a tobacoist, and I think I'm allergic to vaping glycerin-like substances, although I have vaped concentrates on cotton many times on convection vapes, but never on a conduction style like this. The harsh heat on the cotton must be emitting particulates irritating my throat... I can't use this...a full tank of oil that works now, but I don't want to use it.

To remind u guys, I'm not a e-cig vaper, not a tobacoist, and I think I'm allergic to vaping glycerin-like substances, although I have vaped concentrates on cotton many times on convection vapes, but never on a conduction style like this. The harsh heat on the cotton must be emitting particulates irritating my throat... I can't use this...a full tank of oil that works now, but I don't want to use it.

demanding specs

demanding specs

This made me so happy.....

This made me so happy.....

I think as long as they are not over-filled, or stored in a lying flat, sideways position, or stored in a very hot car, (probably with those earlier 2 conditions), it will not leak. Just keep it standing up straight, don't do anything stupid, everything screwed in tight, no leaks!

I think as long as they are not over-filled, or stored in a lying flat, sideways position, or stored in a very hot car, (probably with those earlier 2 conditions), it will not leak. Just keep it standing up straight, don't do anything stupid, everything screwed in tight, no leaks!

) and he asked how to use it. Easy, I said. You hold the button down and hit it, I hand him the mod.

) and he asked how to use it. Easy, I said. You hold the button down and hit it, I hand him the mod.