Monsoon

Well-Known Member

I've been getting fantastic, consistent results with this tech so I wanted to detail and share it here. This method is slightly more advanced and you'll need to buy a heated vacuum purge setup, buchner funnel filtration kit and a dry-sift tumbler. All in it was maybe CAN$1500, it's a good alternative if you can't open blast or don't want to make rosin. The process detailed below is how I make it, but feel free to make your own variations or just use it as inspiration. Constructive criticism is always appreciated and encouraged.

Materials and Tools:

- 100cc Buchner Funnel and 1L flask (try ebay)

- Matching lab filters, both "fast" and "slow" grades (again ebay)

- BestValueVacs flat vacuum chamber with pad heater and 3 CFM pump.

- PollenMaster Dry Sift tumbler

- 500ml and 250ml mason jars

- Everclear or ~94% food grade ethanol

- OilSlick Sheet

- Infrared-Laser Temp gun

Prep:

Dry out your flowers until they're nearly bone dry, break them up into popcorn sized buds or smaller and place in a bag in the freezer for at least 12 hours. Also place a bag of 10-20 nickels in the freezer as well.

Dry Sifting:

Take your flowers out of the freezer, dump into the PollenMaster drum and toss in the 10-20 nickels. The coins help to crush the buds and to push the sift through the screen. Then place the drum in the box and turn it on. The goal here is quantity over quality, I usually get a yield of 40-50% in dry sift and the remainder in the drums should be just stems and coarse plant matter. In the end you'll be left with a mix of gold and green dry sift that will be used for the wash in the next step. Using cleaner dry sift I've found just results in a lower net yield, no difference in end quality.

Once it's all collected and weighed I place up to 25g into each mason jar and place in the freezer along with jars with 250ml of ethanol to be mixed with each one during the wash phase. I do this even for larger batches since it minimizes the time it takes to filter it through the buchner funnel, every second counts here. Again I wait at least 12-24 hours before the next step. I also put saran wrap on the jars prior to capping them to limit the chance of the foam seals on the caps from being exposed to the alcohol just in case it's an issue.

Wash:

Setup your work space so that everything is secure with no risk of anything tipping over. Ideally get a lab stand for the buchner funnel flask or at the very least use a secure non-slip surface. Get your "fast" paper filter in place and pre-wet it with ethanol, you want to filter as quickly as possible to limit chlorophyll leaching out.

For the buchner funnel I suggest hooking it up to your vac chamber under full vac (pump disconnected) and use that instead of a hand pump. That way you can activate and hold the pressure with a flip of the valve. Don't hook up your pump directly, it may be too strong and the alcohol fumes are bad for it.

Start the clock and pour your chilled ethanol into the jar of dry sift jar, cover with the lid and shake hard for 45 seconds. Then pour it out into the buchner funnel with a pre-wetted "fast" paper lab filter and activate the vacuum. You'll want to separate the dry sift from the ethanol under 2-3 minutes before chlorophyll starts leaching out and turns your solution green. If some gets in, you can try leaving it at room temp for a few hours and/or exposing it to sunlight and it should make it golden again. After I finish filtering, I re-filter the solution once or twice more using a few stacked "slow" filters, rinsing the containers with alcohol each time to limit cross-contamination. I've tried doing a second wash but just ended up with a dark green solution that never improved. Might be worth it for edibles or a tincture though but it's not for me.

Evaporation:

I lined the flat vacuum chamber with an OilSlick Sheet so I can make use of the PID controlled heat pad for consistent temperatures which also makes switching to purging easier. I cover it with a 25 micron sheet and blow a fan over it at low heat (under 100F) until most of the alcohol is gone.

Purge:

It's pretty much ready for purging once the oil stops moving when you tilt the container, small pools are fine thanks to the vac. Fold in the edges of the sheet inside the container, put on the top and pull a full vacuum. It may muffin and bubble up violently so keep an eye on it while the vac is running to make sure it doesn't reach the top. I only run the vac briefly since I don't have a cold trap and just seal it off to purge with the pump off. Around 6 hours seems to be enough to get it to the right state for the next step, purge longer if you want a smaller muffin. By then the pools should have spread out and you should be able to touch it quickly without it sticking to your finger.

Fold and Flip:

Now you want to make a smaller slab that's easier to flip and to transfer it to a fresh OilSlick Sheet. Take it out of the chamber and lay it out flat on a table. Then fold it over onto itself, press down on it and then place on a large re-usable ice pack for a few seconds and finally rip the top sheet off. Keep pressing/freezing/ripping until it's uniform slab of the size of your choosing. Once done, place a fresh sheet on top and flip the slab onto it and place back in the chamber for the final purge stage. If the slab is too thick, it will spread out by itself so keep that in mind.

Final Purge:

Let it warm up in the chamber at around 90-100F for around 30 minutes and then pull a full vacuum and run the pump for a few minutes before leaving it under vacuum. The slab should muffin too so watch the height and release pressure if it nears the top. Flip the slab every 6-12 hours until there are no large bubbles forming or 48-72 hours total under vac. Towards the end I'll do some test dabs, once the harshness is diminished and the flavour starts to really come out then I know it's ready.

End Product:

If you did everything correctly you should end up with a beautiful, clear slab of shatter with that won't budder up over time. Most of my yields using good quality indoor buds have hovered around 15%.

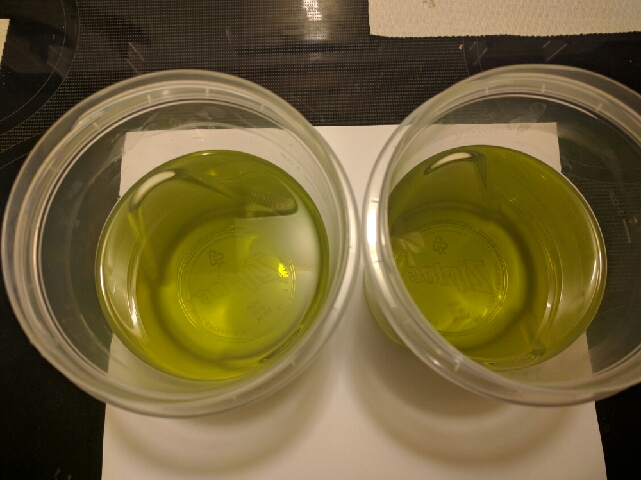

Some recent Jean Guy QWET

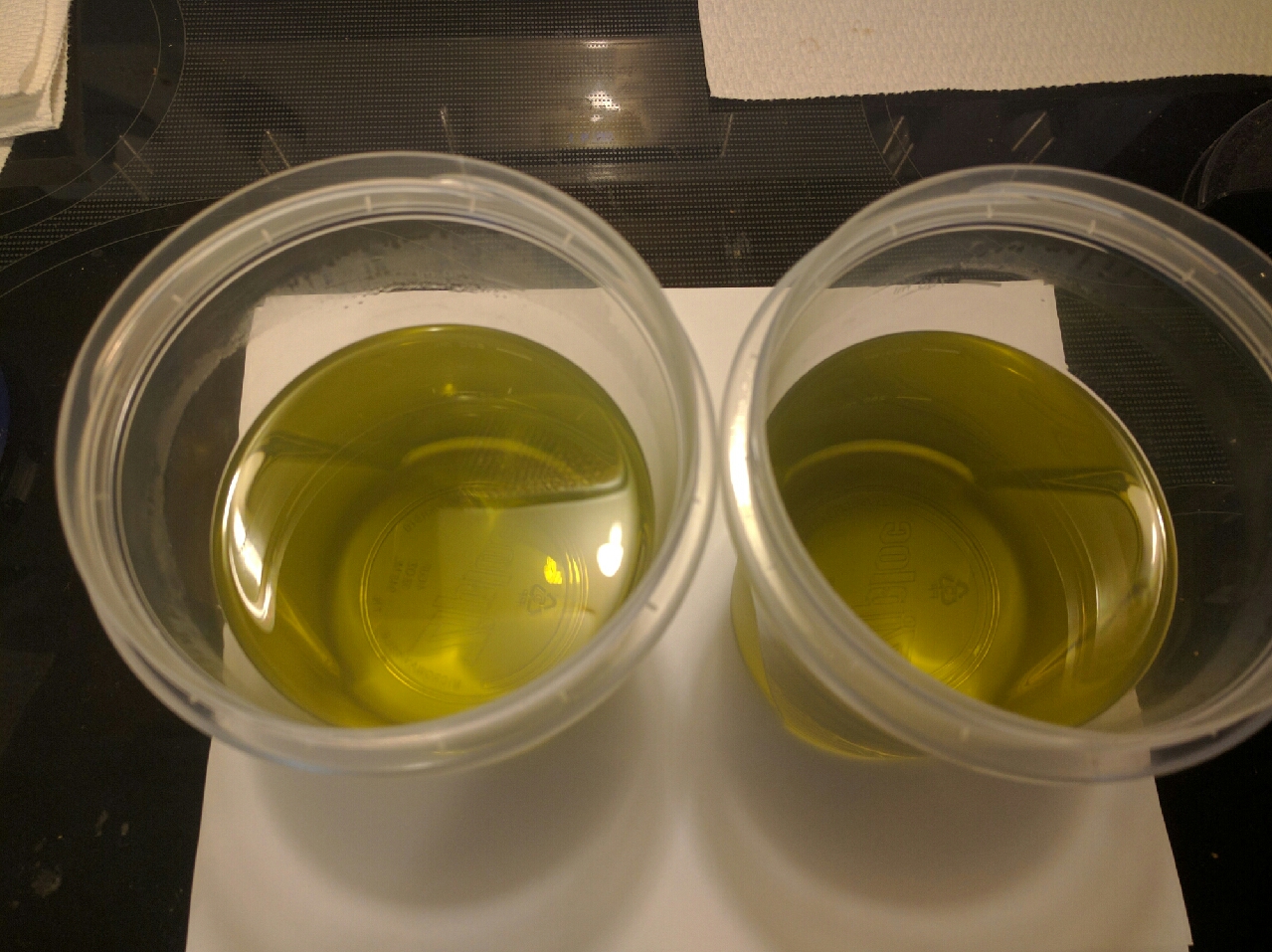

Jack Herer QWET

Materials and Tools:

- 100cc Buchner Funnel and 1L flask (try ebay)

- Matching lab filters, both "fast" and "slow" grades (again ebay)

- BestValueVacs flat vacuum chamber with pad heater and 3 CFM pump.

- PollenMaster Dry Sift tumbler

- 500ml and 250ml mason jars

- Everclear or ~94% food grade ethanol

- OilSlick Sheet

- Infrared-Laser Temp gun

Prep:

Dry out your flowers until they're nearly bone dry, break them up into popcorn sized buds or smaller and place in a bag in the freezer for at least 12 hours. Also place a bag of 10-20 nickels in the freezer as well.

Dry Sifting:

Take your flowers out of the freezer, dump into the PollenMaster drum and toss in the 10-20 nickels. The coins help to crush the buds and to push the sift through the screen. Then place the drum in the box and turn it on. The goal here is quantity over quality, I usually get a yield of 40-50% in dry sift and the remainder in the drums should be just stems and coarse plant matter. In the end you'll be left with a mix of gold and green dry sift that will be used for the wash in the next step. Using cleaner dry sift I've found just results in a lower net yield, no difference in end quality.

Once it's all collected and weighed I place up to 25g into each mason jar and place in the freezer along with jars with 250ml of ethanol to be mixed with each one during the wash phase. I do this even for larger batches since it minimizes the time it takes to filter it through the buchner funnel, every second counts here. Again I wait at least 12-24 hours before the next step. I also put saran wrap on the jars prior to capping them to limit the chance of the foam seals on the caps from being exposed to the alcohol just in case it's an issue.

Wash:

Setup your work space so that everything is secure with no risk of anything tipping over. Ideally get a lab stand for the buchner funnel flask or at the very least use a secure non-slip surface. Get your "fast" paper filter in place and pre-wet it with ethanol, you want to filter as quickly as possible to limit chlorophyll leaching out.

For the buchner funnel I suggest hooking it up to your vac chamber under full vac (pump disconnected) and use that instead of a hand pump. That way you can activate and hold the pressure with a flip of the valve. Don't hook up your pump directly, it may be too strong and the alcohol fumes are bad for it.

Start the clock and pour your chilled ethanol into the jar of dry sift jar, cover with the lid and shake hard for 45 seconds. Then pour it out into the buchner funnel with a pre-wetted "fast" paper lab filter and activate the vacuum. You'll want to separate the dry sift from the ethanol under 2-3 minutes before chlorophyll starts leaching out and turns your solution green. If some gets in, you can try leaving it at room temp for a few hours and/or exposing it to sunlight and it should make it golden again. After I finish filtering, I re-filter the solution once or twice more using a few stacked "slow" filters, rinsing the containers with alcohol each time to limit cross-contamination. I've tried doing a second wash but just ended up with a dark green solution that never improved. Might be worth it for edibles or a tincture though but it's not for me.

Evaporation:

I lined the flat vacuum chamber with an OilSlick Sheet so I can make use of the PID controlled heat pad for consistent temperatures which also makes switching to purging easier. I cover it with a 25 micron sheet and blow a fan over it at low heat (under 100F) until most of the alcohol is gone.

Purge:

It's pretty much ready for purging once the oil stops moving when you tilt the container, small pools are fine thanks to the vac. Fold in the edges of the sheet inside the container, put on the top and pull a full vacuum. It may muffin and bubble up violently so keep an eye on it while the vac is running to make sure it doesn't reach the top. I only run the vac briefly since I don't have a cold trap and just seal it off to purge with the pump off. Around 6 hours seems to be enough to get it to the right state for the next step, purge longer if you want a smaller muffin. By then the pools should have spread out and you should be able to touch it quickly without it sticking to your finger.

Fold and Flip:

Now you want to make a smaller slab that's easier to flip and to transfer it to a fresh OilSlick Sheet. Take it out of the chamber and lay it out flat on a table. Then fold it over onto itself, press down on it and then place on a large re-usable ice pack for a few seconds and finally rip the top sheet off. Keep pressing/freezing/ripping until it's uniform slab of the size of your choosing. Once done, place a fresh sheet on top and flip the slab onto it and place back in the chamber for the final purge stage. If the slab is too thick, it will spread out by itself so keep that in mind.

Final Purge:

Let it warm up in the chamber at around 90-100F for around 30 minutes and then pull a full vacuum and run the pump for a few minutes before leaving it under vacuum. The slab should muffin too so watch the height and release pressure if it nears the top. Flip the slab every 6-12 hours until there are no large bubbles forming or 48-72 hours total under vac. Towards the end I'll do some test dabs, once the harshness is diminished and the flavour starts to really come out then I know it's ready.

End Product:

If you did everything correctly you should end up with a beautiful, clear slab of shatter with that won't budder up over time. Most of my yields using good quality indoor buds have hovered around 15%.

Some recent Jean Guy QWET

Jack Herer QWET