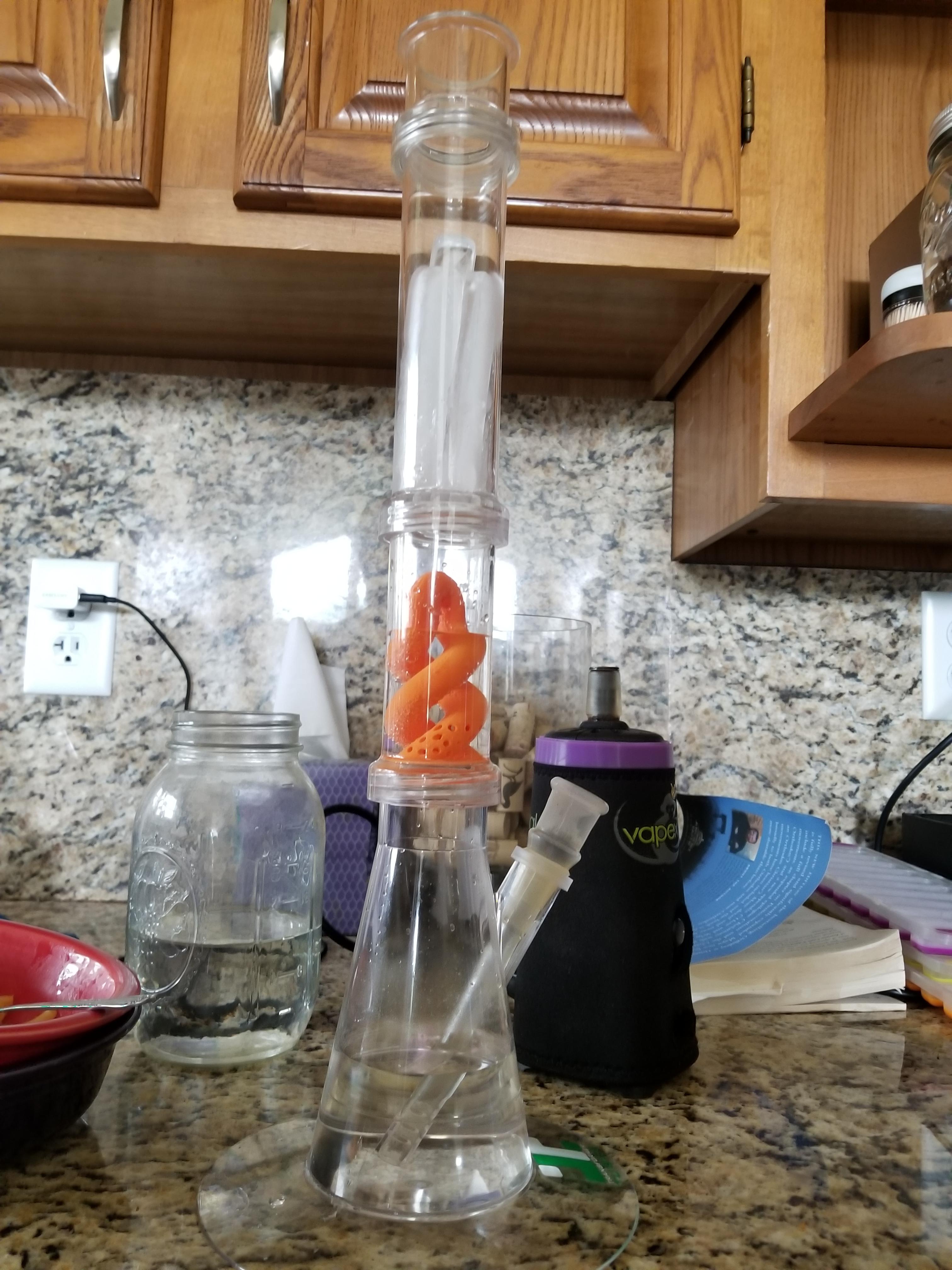

I've seen specialized solutions for acrylic bong in some headshops .. but idont know how effective they are..

Anyway transformer tubes are made out of PC (polycarbonate) which more durable than acryl.

Polycarbonate is a durable material. Although it has high impact-resistance, it has low scratch-resistance. Therefore, a hard coating is applied to polycarbonate eyewear lenses and polycarbonate exterior automotive components. The characteristics of polycarbonate compare to those of polymethyl methacrylate (PMMA, acrylic), but polycarbonate is stronger and will hold up longer to extreme temperature. Polycarbonate is highly transparent to visible light, with better light transmission than many kinds of glass.

Polycarbonate has a glass transition temperature of about 147 °C (297 °F),[6] so it softens gradually above this point and flows above about 155 °C (311 °F).[7] Tools must be held at high temperatures, generally above 80 °C (176 °F) to make strain-free and stress-free products. Low molecular mass grades are easier to mold than higher grades, but their strength is lower as a result. The toughest grades have the highest molecular mass, but are much more difficult to process.

Advised to be sterilized with 120 C water steam..

------------------------------------------------------------

But still can get nasty.. if you overheat it or leave it at direct sun light.

Environmental impact

Disposal

Studies have shown that at high temperatures between 70oC – 80oC, and high humidity, polycarbonates will hydrolyze to Bis-phenol A (BPA). This condition is similar to that observed in most incinerators. After about 30 days under such conditions, surface crystals were formed. Measurements indicated that about 70 wt% of the surface crystals were bisphenol A (BPA).[30] BPA is a compound that is currently on the list of potential environmental hazardous chemicals. It is on the watch list of many countries, such as United States and Germany.[31]

-(-OC6H4)2C(CH3)2CO-)-n + H2O ⟶ {\displaystyle \longrightarrow }

(CH3)2C(C6H4OH)2 + CO2

The leaching of BPA from polycarbonate can also occur at environmental temperature and normal pH (in landfills).The amount of leaching increases as the material becomes older. A study found that the decomposition of BPA in landfills (under anaerobic conditions) will not occur.[31] It will therefore be persistent in landfills. Eventually, it will find its way into water bodies and contribute to aquatic pollution.[31][32]

Photo-oxidation of polycarbonate

In the presence of UV light, oxidation of this polymer yields compounds such as ketones, phenols, o-phenoxybenzoic acid, benzyl alcohol and other unsaturated compounds. This has been suggested through kinetic and spectral studies. The yellow color formed after long exposure to sun can also be related to further oxidation of phenolic end group[33]

(OC6H4)2C(CH3)2CO )n + O2 , R* → (OC6H4)2C(CH3CH2)CO)n

This product can be further oxidized to form smaller unsaturated compounds. This can proceed via two different pathways, the products formed depends on which mechanism takes place.

Pathway A

(OC6H4)2C(CH3CH2)CO + O2, H* ⟶ {\displaystyle \longrightarrow }

HO(OC6H4)OCO + CH3COCH2(OC6H4)OCO

Pathway B

(OC6H4)2C(CH3CH2)CO)n + O2, H* ⟶ {\displaystyle \longrightarrow }

OCO(OC6H4)CH2OH + OCO(OC6H4)COCH3

Photo-oxidation reaction.[34]

Photo-aging reaction

Photo-aging is another degradation route for polycarbonates. Polycarbonate molecules (such as the aromatic ring) absorb UV radiation. This absorbed energy causes cleavage of covalent bonds which initiates the photo-aging process. The reaction can be propagated via side chain oxidation, ring oxidation or photo-fries rearrangement. Products formed include phenyl salicylate, dihydroxybenzophenone groups, and hydroxydiphenyl ether groups.[33][35][36]

n(C16H14O3) ⟶ {\displaystyle \longrightarrow }

C16H17O3 + C13H10O3

Polycarbonate Phenyl salicylate 2,2-dihydroxybenzophenone

Thermal degradation

Waste polycarbonate will degrade at high temperatures to form solid, liquid and gaseous pollutants. A study showed that the products were about 40–50 wt.% liquid, 14–16 wt.% gases, while 34–43 wt.% remained as solid residue. Liquid products contained mainly phenol derivatives (∼75wt.%) and bisphenol (∼10wt.%) also present.[35] Therefore, burning of these discs is also not a viable method of disposal.

Phenol derivatives are environmental pollutants, classified as Volatile Organic Compounds (VOC). Studies show they are likely to facilitate ground level ozone formation and increase photo-chemical smog.[37] In aquatic bodies, they can potentially accumulate in organisms. They are persistent in landfills, do not readily evaporate and would remain in the atmosphere.[38]

... Btw there are adapters screw to 14/18mm for those metal downstems

... Btw there are adapters screw to 14/18mm for those metal downstems