Hello there everyone!

I wanted to drop in and show off the first version of my recent creation. I've been trying to design an arduino compatible development board that would make it easy on myself (and anyone else) to experiment with custom heating algorithms, various power sources and advanced electronics like screens or special sensors. Basically, this is a complete development board for a vaporizer, a blank slate of electronics waiting to be programmed with your control algorithm. You just need to add the power supply and the heater/thermocouple.

My intentions with this are to make the development process of making a vaporizer a lot easier. I have so many idea's I want to experiment with, and just using a straight PID controller means your locked into one type of control algorithm. This will make that a lot easier, especially the programming portion, since the chip can be reprogrammed in circuit hundreds of thousands of times.

Arduino is awesome, because it removes so much of the hassle of working with microcontrollers out of the development process. You can write your programs in the easy to learn, C based programming language, and upload it at the touch of a button via a programmer, or in this case, just plugging the board itself in to a computer via USB. There is already an Arduino implementation of PID control that can be drawn on, and lots of other cool stuff.

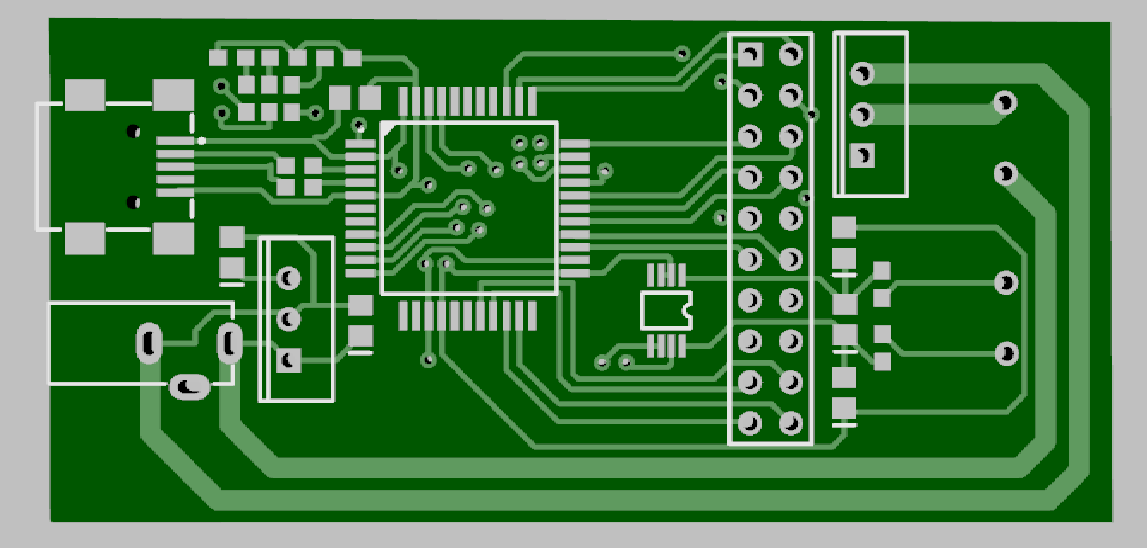

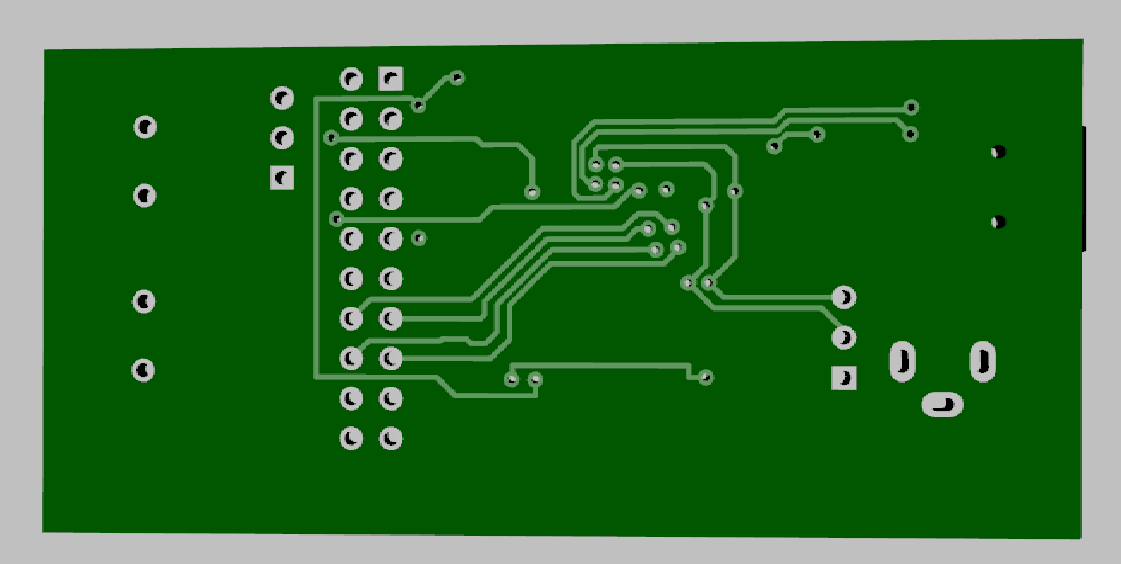

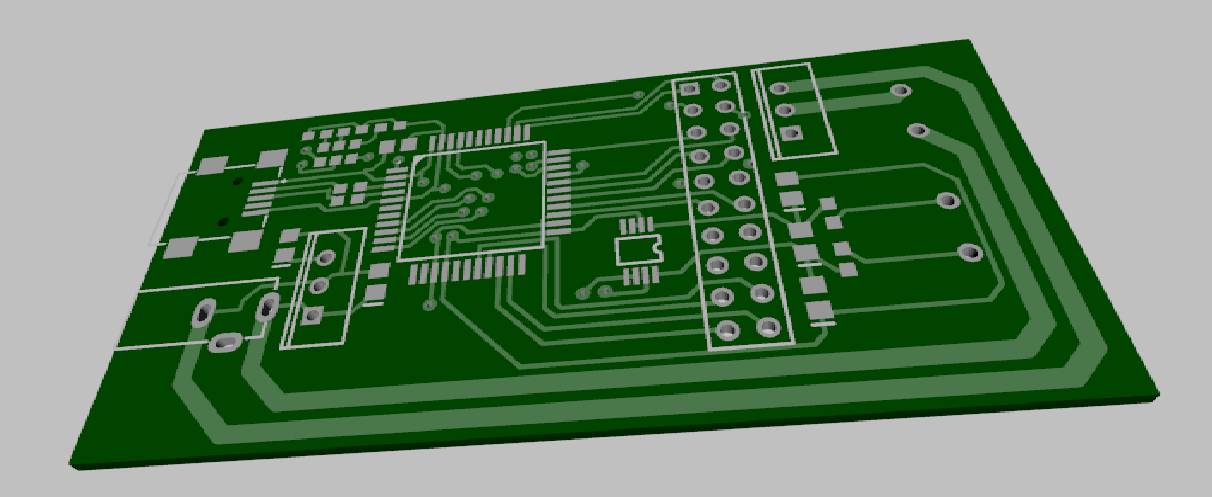

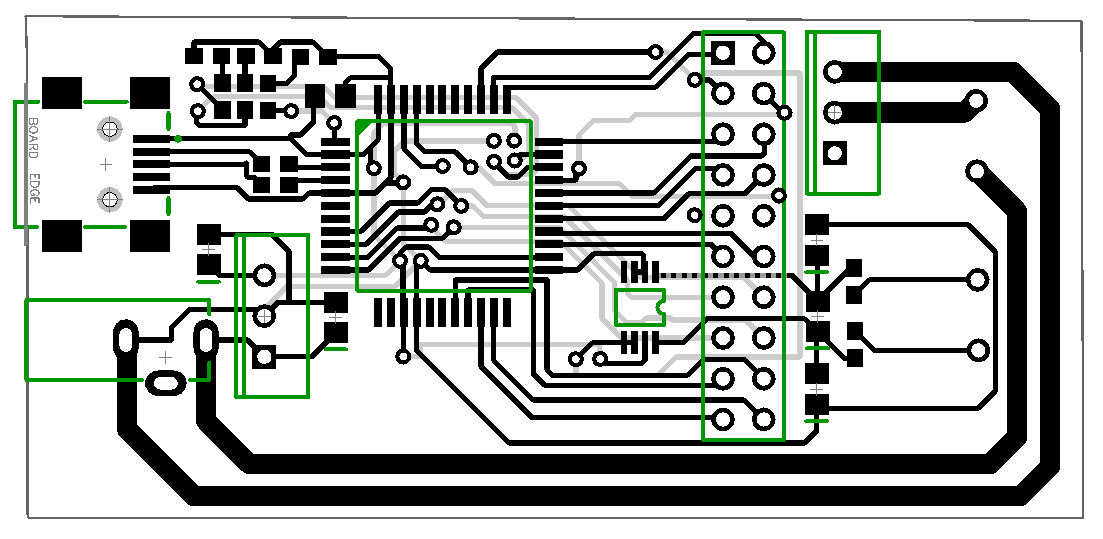

Here's some pictures, I've only got 3D renderings at this point since I still need to get my prototypes produced. But some of you might be able to make use of the CAD files to make your own, so I've added them to the end of the post. I'll make a dedicated thread for this once I've made more headway.

This board supports any DC voltage from 12 - 30V, keeping the high voltage power isolated from the low voltage circuitry. A beefy power regulator keeps the microcontroller powered, and provides up to 500mAh of extra power for additional lights, screen backlights and things of the sort. There's a 20 pin expansion header through which you can get 5V power, TX/RX serial, SPI protocol for external devices, and 6 GPIO with 4 ADC. You can also read the thermocouple state, and interact with the transistor gate. You can also read the thermocouple from USB.

The heater is modulated by a large MOSFET-style transistor, which is connected to a PWM output, allowing for either normal on/off style control or sophisticated modulation. The thermocouple input has a low-pass filter on it to prevent the thermocouple leads from acting as an antenna on longer cords, making temperature detection extremely accurate. There's also three lights for status/temperature indication.

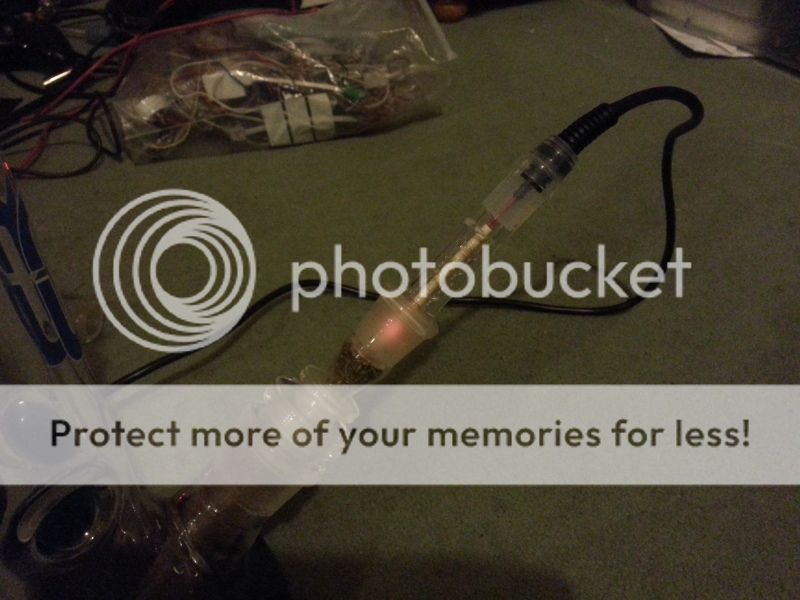

At the moment I've got it controlling a cartridge style heating element (the yihua ones @

SquidgyB posted) at 250 degrees C. The rudimentary control program I have made keeps it accurate to about +- 3 degrees Celcius, and I'm working on one that is based off of @

Hippie Dickie 's bud toaster algorithm.

Here's a pack with the CAD files, Bill of Materials, and a labelled diagram of the parts in it. I'm hoping to get some of these boards produced soon. I used DipTrace to make these files, it's free and great. I'm hoping to have this powering a vape as soon as possible.