-

SCAM WARNING! See how this scam works in Classifieds.

-

The Frolic by Limelight Giveaway is over. Congratulations to the winner: Numerous_Nothing!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Winegums' Woodcraft

- Thread starter Winegums

- Start date

I think I spoiled my Wife with this early birthday gift. She recently got into needle felting and wanted a case to hold all her supplies with her on the go. She also had some very specific requests that made for a good challenge of my wood working skills. The diagonal stripes on the sides and ends were by far the hardest part to get perfect. Making the laminated wood took the better part of a day but was ultimately worth it in spades.

Her other request was a completely symmetrical case with three storage areas for her wool, handle and needles. It was less of a challenge than working with the laminated wood but still required another rethink of the design. The solution was a pull out drawer from the middle which will store her wool and identical storage bays on either side that were modified from my vapcap holder design.

This is seriously one of the prettiest items I've created to date.

Her other request was a completely symmetrical case with three storage areas for her wool, handle and needles. It was less of a challenge than working with the laminated wood but still required another rethink of the design. The solution was a pull out drawer from the middle which will store her wool and identical storage bays on either side that were modified from my vapcap holder design.

This is seriously one of the prettiest items I've created to date.

nickdanger

Collector of Functional Art

She's one lucky lady!! That's a beautiful creation!

GreenHopper

20 going on 60

I think that's worth at least 5 free passes.

Stunning work there man.

Stunning work there man.

WakeAndVape

VapeLife X

so do the XL cases in your store have a separate herb compartment...or are there just two???

Just two for more flexibility, but I can make the version with a separate compartment for the test tube.so do the XL cases in your store have a separate herb compartment...or are there just two???

WakeAndVape

VapeLife X

do you think the current version can fit two dube-tubes?Just two for more flexibility, but I can make the version with a separate compartment for the test tube.

I think the most important thing for ME to store is the VC, herbs and maybe a couple spare parts...but I always wanted a place to store avb.

as far as the lighter... I was never married to the thought of having it in the stash, sothags not a concern...fuck I want one!

You can fit up to three tubes on the storage side in the version that is up in the store right now.do you think the current version can fit two dube-tubes?

I think the most important thing for ME to store is the VC, herbs and maybe a couple spare parts...but I always wanted a place to store avb.

as far as the lighter... I was never married to the thought of having it in the stash, sothags not a concern...fuck I want one!

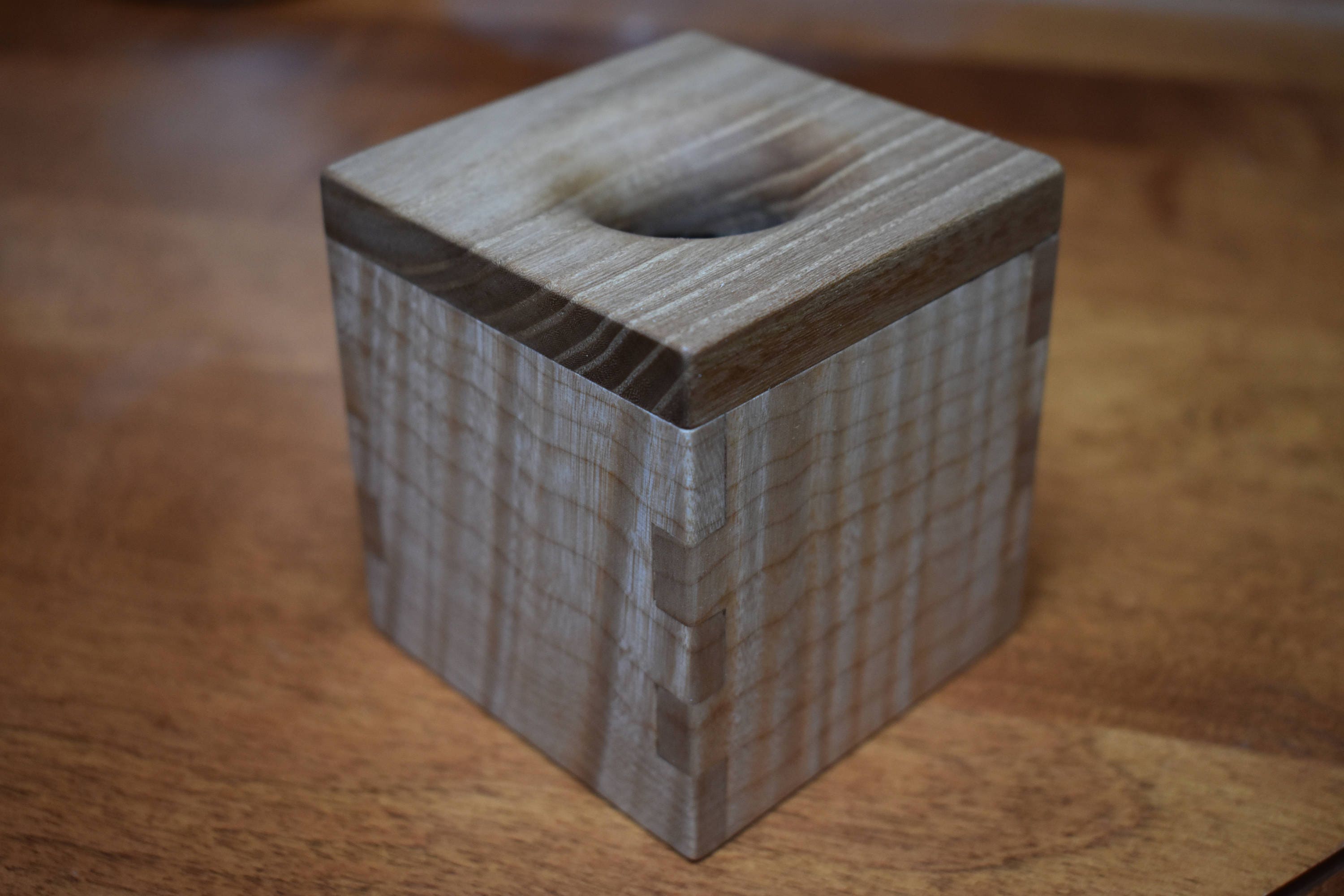

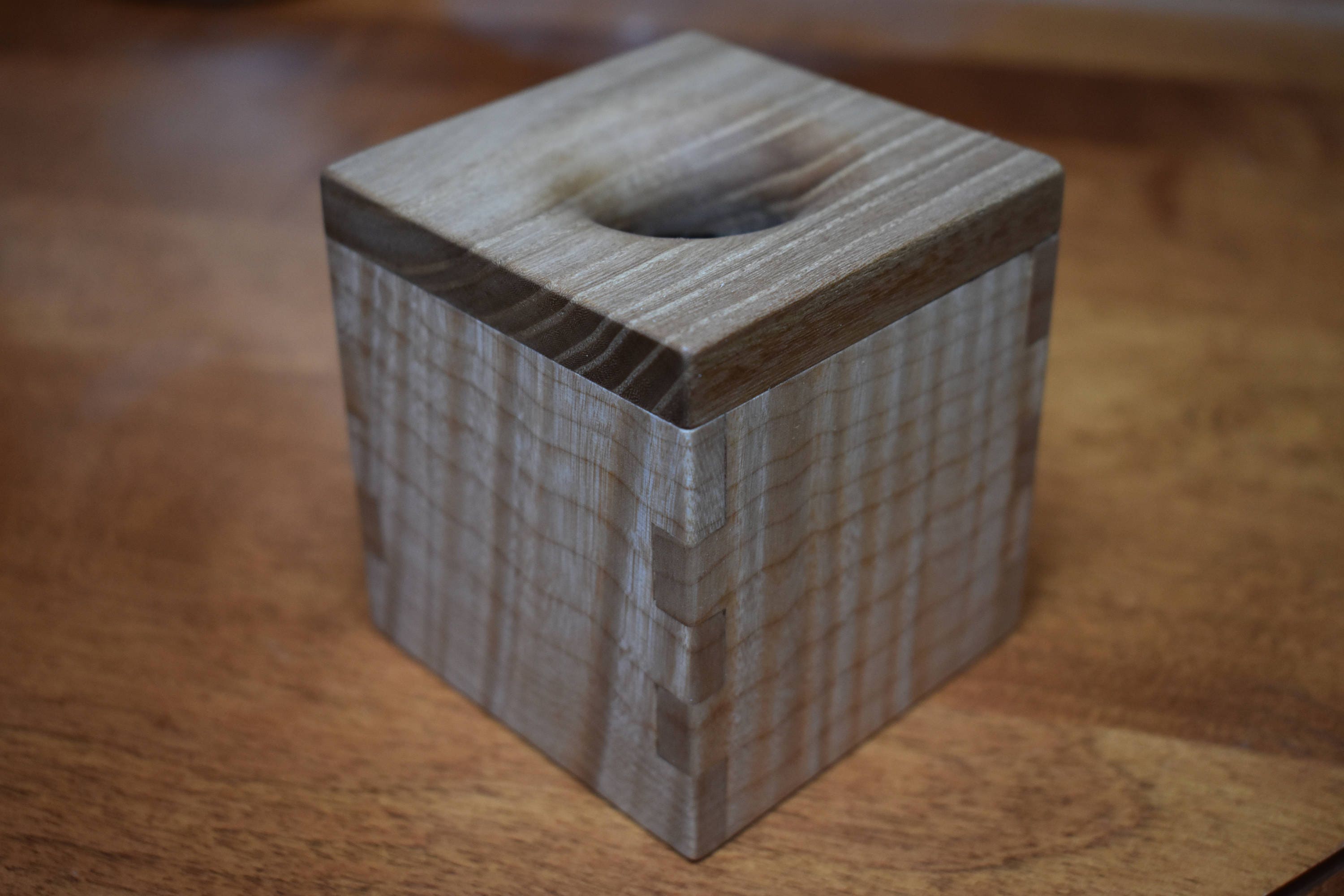

Here's a sneak peek the prototype ABV bin. By chance it lines up with my XL maple stash so that I have a magnet handy. Having a stable sturdy container that I can dump my ABV into is something I didn't even know I needed until now.

Edit: I'd also like to add that I'm in the process of reworking how I do the liner in my stems. The source of seamless stainless tubing that I was using has disappeared and I've been forced to find a suitable replacement. I have more SS tubing on the way from another supplier and also some Brass tubing which might be the better option going forward. As of right now I do not have any material that I can line the stems with besides thin wall tubing. I won't be taking on custom ordered stems until this is sorted out.

As a heads up I will gone to California from Oct 17 - 28 and my Etsy shop will be closed during that time. I will still be checking the forums and replying when I can, but I will not be able to ship items or do any work during that time.

Edit: I'd also like to add that I'm in the process of reworking how I do the liner in my stems. The source of seamless stainless tubing that I was using has disappeared and I've been forced to find a suitable replacement. I have more SS tubing on the way from another supplier and also some Brass tubing which might be the better option going forward. As of right now I do not have any material that I can line the stems with besides thin wall tubing. I won't be taking on custom ordered stems until this is sorted out.

As a heads up I will gone to California from Oct 17 - 28 and my Etsy shop will be closed during that time. I will still be checking the forums and replying when I can, but I will not be able to ship items or do any work during that time.

Last edited:

I received a custom 14mm maple stem and XL stash a few days ago. So beautiful.

The stash is really lovely, my Omni XL looks great inside it. I plan to get a Aomai lighter, which should fit in it, and there should be plenty of room for small herb and abv containers too. At that point it will be my absolute perfect stash. It is really well built, and the magnets keep the sides in well; there isn't a chance of it opening accidentally.

And the 14mm maple stem is perfect, I put an M tip with grooves filed into the top of it, and it was super satisfying to use with water.

@Winegums, you are such a wonderful craftsman, thank you so much. Enjoy your vacation.

The stash is really lovely, my Omni XL looks great inside it. I plan to get a Aomai lighter, which should fit in it, and there should be plenty of room for small herb and abv containers too. At that point it will be my absolute perfect stash. It is really well built, and the magnets keep the sides in well; there isn't a chance of it opening accidentally.

And the 14mm maple stem is perfect, I put an M tip with grooves filed into the top of it, and it was super satisfying to use with water.

@Winegums, you are such a wonderful craftsman, thank you so much. Enjoy your vacation.

The Elm trays are now drying after having their final coat of finish applied this morning.

I also spent some time on making the first of a few ABV bins. I decided against making the lid dovetailed and went for a drop in lid.

Finally, I have extruded Brass tubing on hand now that will be replacing my SS tubing. I've had to switch materials due to inaccuracies of the SS tubing causing fitment issues. I'll be taking custom orders again and also producing a few metal and burl pieces this coming week.

I also spent some time on making the first of a few ABV bins. I decided against making the lid dovetailed and went for a drop in lid.

Finally, I have extruded Brass tubing on hand now that will be replacing my SS tubing. I've had to switch materials due to inaccuracies of the SS tubing causing fitment issues. I'll be taking custom orders again and also producing a few metal and burl pieces this coming week.

The ABV containers and Trays are up in my Etsy Shop now.

https://www.etsy.com/listing/569655847/wooden-box-with-funnel-lid

https://www.etsy.com/listing/569657097/wooden-tray

https://www.etsy.com/listing/569655847/wooden-box-with-funnel-lid

https://www.etsy.com/listing/569657097/wooden-tray

Yes, I have plans to make it in oak, cherry and walnut. I can also stain them if desired.The ABV container looks very nice. Will it be available in other, more darker woods?

I'm not quite sure what you mean? You're going to have to explain it a bit more.Regarding construction perhaps a closing knob in the middle could help to empty the bowl and tighten the container. I mean something like that:

Hogni

Honi soit qui mal y pense

It's nearly the same as yours just with an additional half-ball shaped knob in the middle atttached to the downpart which is properly fitting into the hole of the upper part. There are two advantages in construction

1. the container will be closed (holding the load safer and keeps back more odor of ABV

2. the knob helps to empty your bowl because you can knock the bowl on the knob

Hope you're understanding what I mean?

1. the container will be closed (holding the load safer and keeps back more odor of ABV

2. the knob helps to empty your bowl because you can knock the bowl on the knob

Hope you're understanding what I mean?

I get what you mean now, but the actual construction of it might be a bit tricky.It's nearly the same as yours just with an additional half-ball shaped knob in the middle atttached to the downpart which is properly fitting into the hole of the upper part. There are two advantages in construction

1. the container will be closed (holding the load safer and keeps back more odor of ABV

2. the knob helps to empty your bowl because you can knock the bowl on the knob

Hope you're understanding what I mean?

It's a lot more work that's for sure, likely more work than it would be worth.Sorry, why that? More work for sure but what makes it tricky?

There's the difficulty of getting everything just right where there's enough space for stuff to fall down but also have the knob protrude. A secondary profile would need to be routed into the backside of the lid so that the knob would fit far up enough. This would involve making a routing template and doing a tedious setup to align everything perfectly.

I don't have a spherical lathing attachment which will make the production of the knob take quite a while and require each to be hand fitted to the lid

There's also the matter of attaching the knob to the lid solidly without obscuring the opening of the container too much. The thicker the supports for the knob the more likely that material will get stuck on it rather than falling down.

Lastly I would have to spend time dimensioning, lathing and producing all the pieces of wood required for the additional feature.

The amount of effort to add it and do the job properly would drive the cost up quite a bit. It would add a lot of complexity for very little functionality. I've been using my prototype bin for a week or two now and I've had no issue with tapping out my vapourizers on the edge of the hole.