-

SCAM WARNING! See how this scam works in Classifieds.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What is the whole process to make high quality BHO oil ?

- Thread starter dabboy

- Start date

-

- Tags

- bho concentrate

miguelovic

Well-Known Member

Skunkpharm. Go from there and you'll be on the right track.

Silver420Surfer

Downward spiral

A research assistant.

Why tie up the boards when a simple Google search would suffice?

Why tie up the boards when a simple Google search would suffice?

Paka-cholo

Flaccid Member

Ask Herbivore

muunch

hotboxing the cockpit

@herbivore21 does solventless. I'm not sure if he messes with solvents other than water and ice.

herbivore21

Well-Known Member

It is hard to say without knowing what kind of closed loop extractor you have. Also the kind of vac chamber and heating pad. It sounds like you have most, if not all of the things that you need, but there is much more to resolve here.I have a small passive closed loop extractor system (45gram),a vacuum chamber and vacuum pump , a heating pad . Does it enough to run the whole process , whet else equipment should I buy if I want to make high quality BHO at home ?

@muunch you are right to say that I mostly only use solventless methods these days and that even when I use water, it is not being used as a solvent. However, many will also know that I cut my teeth producing high quality solvent extracts for myself before I learned to make the true fire (ie: full melt hash). I still regularly offer assistance in this space, but am very careful about such advice as IMO most people should not be trying their hand at working with explosive/flammable solvents.

@dabboy What kind of vacuum pump do you have? Please provide make and model. Also if you could provide a link etc to the kind of chamber you are using and especially include the closed loop extractor make and model?

Also I am somewhat busy IRL at the moment so in case it takes me a little while to follow up to responses, I wonder if my friend @SamuraiSam could help here too, since he is processing large scale with CLS tek on the regular IIRC. He most assuredly knows his shit and will have good advice to provide here

In the meantime, please do not mess around with your new equipment if you are not sure how to. Butane is very, very risky shit to mess with if you're not completely sure of how to do so safely.

@dabboy if I may also ask, do you have any existing experience with butane extraction?

SamuraiSam

Extraction Technician

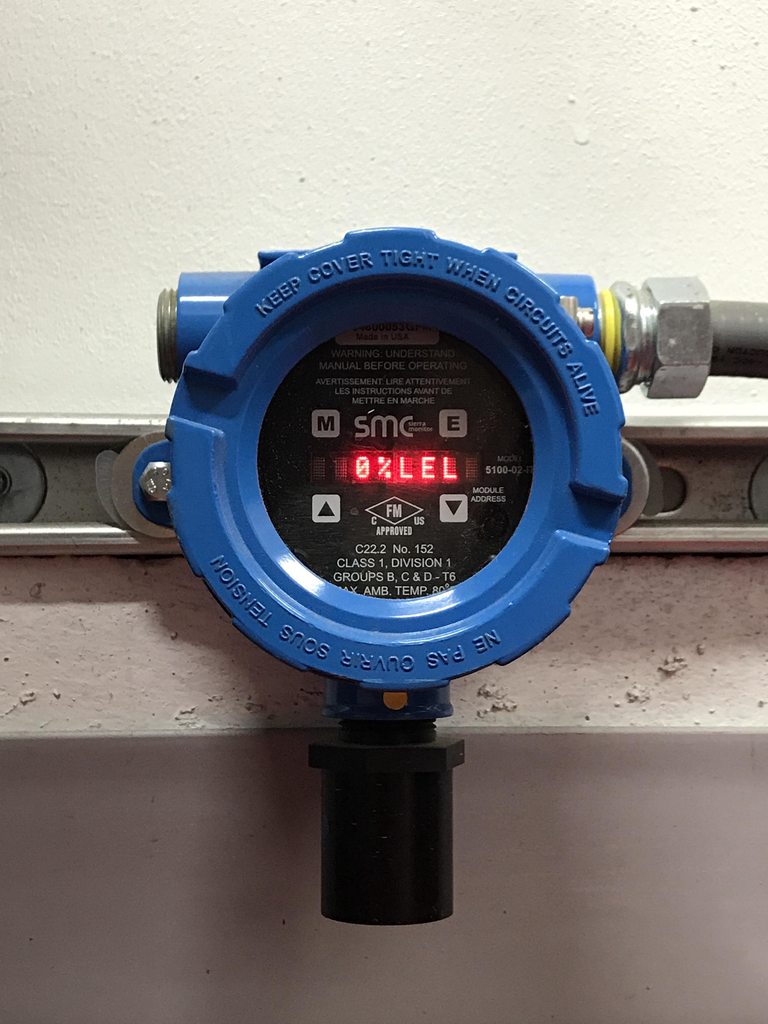

I do not advocate 'making BHO at home'. I would suggest working with solvents like butane in a Class 1, Division 2, or C1D1 room with high airflow exchange rates, top-down airflow (exhausts at floor level- imperative as these flammable gasses are heavier than air) and no ignition sources.

If you are going to take a CLS outdoors, build a proper platform far away from any buildings.. butane will fall to the ground and can cover a very large surface area, creeping back in under doors into basements or garages with pilot lights for water heaters or furnaces. 20 feet outside your house is not a safe place to discharge butane. Don't just throw a piece of wood on the ground and set a tall closed loop on top. Many small systems are too easy to tip over. Please resarch behavior of butane and spend considerable time sober thinking of safe procedures before proceeding.

I wouldn't be a good person to teach you how to make BHO start to finish, and if you have not ever done it before, I would suggest simply not doing it. There are far simpler, safer procedures to try out at home, first.

I could tell you some of the places I learned things if you want to try to help yourself. Skunkpharm, the first site posted by @miguelovic , is a fantastic starting point:

https://skunkpharmresearch.com/bho-extraction/

, and I hope you're very familiar with them by now... If any of these information sources are new-to-you as someone going out and researching how to make BHO, I'd be worried, because the type of person that makes posts asking others to spoon feed them information are usually not the kind of person that has the ability to research topics of such paramount importance as safety precautions with regards to flammable solvents.

I learned how to make BHO in 2006/7 based off Indra's original boffo-butane-PVC pipe post: https://erowid.org/plants/cannabis/cannabis_info13.shtml Things have come a very long way since then.

It's worth noting that NO ONE uses PVC pipe for this purpose anymore, and only the worst of the worst blast cans of disgusting contaminated lighter-refill butane straight out of cans- these multiple-compound cans of solvent contain a blend of gasses along with central nervous system depressants like mercaptan, machining oils from the manufacture and forming of rolling the cans... This is why obtaining pure solvent is required. (I get 99.97% pure butane and propane from gas suppliers at work, and distill that another time before adding it to the solvent tank) Stainless steel tubes are strongly suggested. If you have a small CLS, you are good to go in the materials department. Inspect your gaskets throughly and make sure they are compatible with the solvent you are using- viton seals are strongly suggested for tri-clamp gaskets.

if you are recovering passively, one of the best video series you could watch would be from Bret Maverick. Watch all of these videos: https://www.youtube.com/playlist?list=PLzvEtJyVfqQa5qm5rwAMc-frOqA1elYBu

Once you understand how the process works you should be able to determine for yourself whether you have all the requisite materials needed to proceed safely. I have all the same questions as @herbivore21 and also would like to know if your CLS has a pour-out collection pot, or valve operated dispenser, and what type of container / material you will be pouring out into, for insertion into your purging chamber? How much of the solvent can you recover out of your collection pot before pour out, i.e. will you need to 'boil off' excess solvent before you can put the oil into a vacuum chamber, or can you pull a vacuum inside your CLS' pot?

If you are going to take a CLS outdoors, build a proper platform far away from any buildings.. butane will fall to the ground and can cover a very large surface area, creeping back in under doors into basements or garages with pilot lights for water heaters or furnaces. 20 feet outside your house is not a safe place to discharge butane. Don't just throw a piece of wood on the ground and set a tall closed loop on top. Many small systems are too easy to tip over. Please resarch behavior of butane and spend considerable time sober thinking of safe procedures before proceeding.

I wouldn't be a good person to teach you how to make BHO start to finish, and if you have not ever done it before, I would suggest simply not doing it. There are far simpler, safer procedures to try out at home, first.

I could tell you some of the places I learned things if you want to try to help yourself. Skunkpharm, the first site posted by @miguelovic , is a fantastic starting point:

https://skunkpharmresearch.com/bho-extraction/

, and I hope you're very familiar with them by now... If any of these information sources are new-to-you as someone going out and researching how to make BHO, I'd be worried, because the type of person that makes posts asking others to spoon feed them information are usually not the kind of person that has the ability to research topics of such paramount importance as safety precautions with regards to flammable solvents.

I learned how to make BHO in 2006/7 based off Indra's original boffo-butane-PVC pipe post: https://erowid.org/plants/cannabis/cannabis_info13.shtml Things have come a very long way since then.

It's worth noting that NO ONE uses PVC pipe for this purpose anymore, and only the worst of the worst blast cans of disgusting contaminated lighter-refill butane straight out of cans- these multiple-compound cans of solvent contain a blend of gasses along with central nervous system depressants like mercaptan, machining oils from the manufacture and forming of rolling the cans... This is why obtaining pure solvent is required. (I get 99.97% pure butane and propane from gas suppliers at work, and distill that another time before adding it to the solvent tank) Stainless steel tubes are strongly suggested. If you have a small CLS, you are good to go in the materials department. Inspect your gaskets throughly and make sure they are compatible with the solvent you are using- viton seals are strongly suggested for tri-clamp gaskets.

if you are recovering passively, one of the best video series you could watch would be from Bret Maverick. Watch all of these videos: https://www.youtube.com/playlist?list=PLzvEtJyVfqQa5qm5rwAMc-frOqA1elYBu

Once you understand how the process works you should be able to determine for yourself whether you have all the requisite materials needed to proceed safely. I have all the same questions as @herbivore21 and also would like to know if your CLS has a pour-out collection pot, or valve operated dispenser, and what type of container / material you will be pouring out into, for insertion into your purging chamber? How much of the solvent can you recover out of your collection pot before pour out, i.e. will you need to 'boil off' excess solvent before you can put the oil into a vacuum chamber, or can you pull a vacuum inside your CLS' pot?

Last edited:

PoopMachine

Well-Known Member

Ive run my machine a couple of times. While Im not an expert, I do feel like Im being safe about it and the results have been pretty decent.

Buy a lot of dry ice and I would recommend getting a -4 hose that can pierce the cans if you plan to fill it that way. That way you dont run the risk of any butane escaping into the atmosphere. I bought a 20# cylinder from Best Val Vacs and filled mine with that. I recovered all but a very small amount of butane on my runs. If you do it right, the only time butane will be exposed is when you open the can to pour the results onto a pad to purge it.

Just be patient. Recovery takes a long time. If you have a sight glass in your unit, you can see whats going on with a flash light looking in there.

Also, be sure to pull the whole system under a vacuum before you start.

Buy a lot of dry ice and I would recommend getting a -4 hose that can pierce the cans if you plan to fill it that way. That way you dont run the risk of any butane escaping into the atmosphere. I bought a 20# cylinder from Best Val Vacs and filled mine with that. I recovered all but a very small amount of butane on my runs. If you do it right, the only time butane will be exposed is when you open the can to pour the results onto a pad to purge it.

Just be patient. Recovery takes a long time. If you have a sight glass in your unit, you can see whats going on with a flash light looking in there.

Also, be sure to pull the whole system under a vacuum before you start.

herbivore21

Well-Known Member

@dabboy This is among the most valuable advice that can be given to the would-be home extractor. As Sam says, it will be a very long road to extracting BHO safely if you do not have any experience/knowledge already.I wouldn't be a good person to teach you how to make BHO start to finish, and if you have not ever done it before, I would suggest simply not doing it. There are far simpler, safer procedures to try out at home, first.

Given that it seems that you have no experience making BHO, you would have been better off not to have already purchased equipment and instead tried rosin tek. Of course, as Sam says above, those resources can help you to start to understand the sorts of knowledge you need to start thinking about safe extraction methods with your own equipment, but you should not be attempting this without a great deal more reading and ideally, some one-to-one guidance/assistance provided in person by a qualified and experienced extractor.

What Sam says above about the specifications of a room which would provide safety for BHO extraction is sound advice, and you really should not be fucking with butane indoors if you aren't in this scenario. Any failure that vents butane into a closed space is bad, bad fucking news. Butane can cause the air in a space to become flammable at concentrations as low as 2% by volume. In the presence of any spark, flame, pilot or other source of ignition, butane will catch fire at temps as low as -76f. A small amount of ignited butane can cause an incredibly deadly explosion and fire.

I notice so many people giving up on rosin after a half-assed attempt using a hair straightener with their own body weight (basically, the poor results that they saw were due to insufficient pressure usually). These same people frequently approach people like myself and others with queries about trying BHO. Generally speaking, this needs to be understood by all: Rosin is as easy as it gets for extraction purposes. If you can't apply enough force with a sufficiently sturdy pair of solid objects that are hot enough to press oil out of your buds, then you have absolutely no business going near solvents for extracting. Solvents are far more complicated to use and entail greater safety risks to you and anyone around you.

Also if you do not have access to sufficiently clean purified butane from a gas supplier, you're also going to be hamstrung from the start in your BHO pursuits. Canned tane can bring in all kinds of problems as my friend @SamuraiSam points out. Mercaptans and mystery oil are no good in your dabs.

Please do heed the safety advice that Sam and I have provided here. We don't need anymore butane accidents or contaminated BHO in the community.

Last edited:

jane621

Unapproved commercial account.

I do not advocate 'making BHO at home'. I would suggest working with solvents like butane in a Class 1, Division 2, or C1D1 room with high airflow exchange rates, top-down airflow (exhausts at floor level- imperative as these flammable gasses are heavier than air) and no ignition sources.

If you are going to take a CLS outdoors, build a proper platform far away from any buildings.. butane will fall to the ground and can cover a very large surface area, creeping back in under doors into basements or garages with pilot lights for water heaters or furnaces. 20 feet outside your house is not a safe place to discharge butane. Don't just throw a piece of wood on the ground and set a tall closed loop on top. Many small systems are too easy to tip over. Please resarch behavior of butane and spend considerable time sober thinking of safe procedures before proceeding.

I wouldn't be a good person to teach you how to make BHO start to finish, and if you have not ever done it before, I would suggest simply not doing it. There are far simpler, safer procedures to try out at home, first.

I could tell you some of the places I learned things if you want to try to help yourself. Skunkpharm, the first site posted by @miguelovic , is a fantastic starting point:

https://skunkpharmresearch.com/bho-extraction/

, and I hope you're very familiar with them by now... If any of these information sources are new-to-you as someone going out and researching how to make BHO, I'd be worried, because the type of person that makes posts asking others to spoon feed them information are usually not the kind of person that has the ability to research topics of such paramount importance as safety precautions with regards to flammable solvents.

I learned how to make BHO in 2006/7 based off Indra's original boffo-butane-PVC pipe post: https://erowid.org/plants/cannabis/cannabis_info13.shtml Things have come a very long way since then.

It's worth noting that NO ONE uses PVC pipe for this purpose anymore, and only the worst of the worst blast cans of disgusting contaminated lighter-refill butane straight out of cans- these multiple-compound cans of solvent contain a blend of gasses along with central nervous system depressants like mercaptan, machining oils from the manufacture and forming of rolling the cans... This is why obtaining pure solvent is required. (I get 99.97% pure butane and propane from gas suppliers at work, and distill that another time before adding it to the solvent tank) Stainless steel tubes are strongly suggested. If you have a small CLS, you are good to go in the materials department. Inspect your gaskets throughly and make sure they are compatible with the solvent you are using- viton seals are strongly suggested for tri-clamp gaskets.

if you are recovering passively, one of the best video series you could watch would be from Bret Maverick. Watch all of these videos: https://www.youtube.com/playlist?list=PLzvEtJyVfqQa5qm5rwAMc-frOqA1elYBu

Once you understand how the process works you should be able to determine for yourself whether you have all the requisite materials needed to proceed safely. I have all the same questions as @herbivore21 and also would like to know if your CLS has a pour-out collection pot, or valve operated dispenser, and what type of container / material you will be pouring out into, for insertion into your purging chamber? How much of the solvent can you recover out of your collection pot before pour out, i.e. will you need to 'boil off' excess solvent before you can put the oil into a vacuum chamber, or can you pull a vacuum inside your CLS' pot?

Really helpful for me, thanks a lot!

SamuraiSam

Extraction Technician

You are most welcome!Really helpful for me, thanks a lot!

Thought I'd share one of my favorite things, in the lab I work at.