I felt like I spent the day in a miniature world...

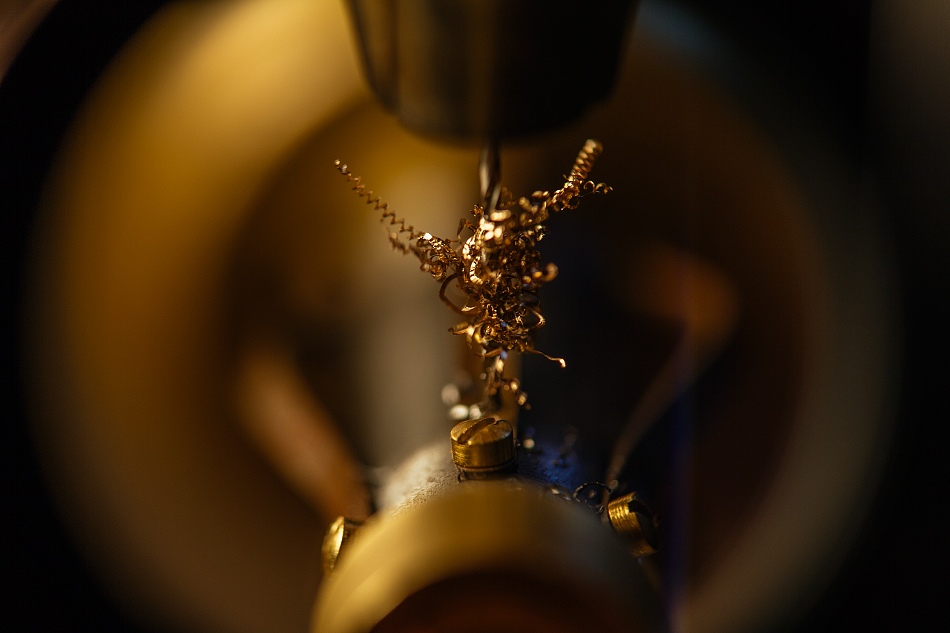

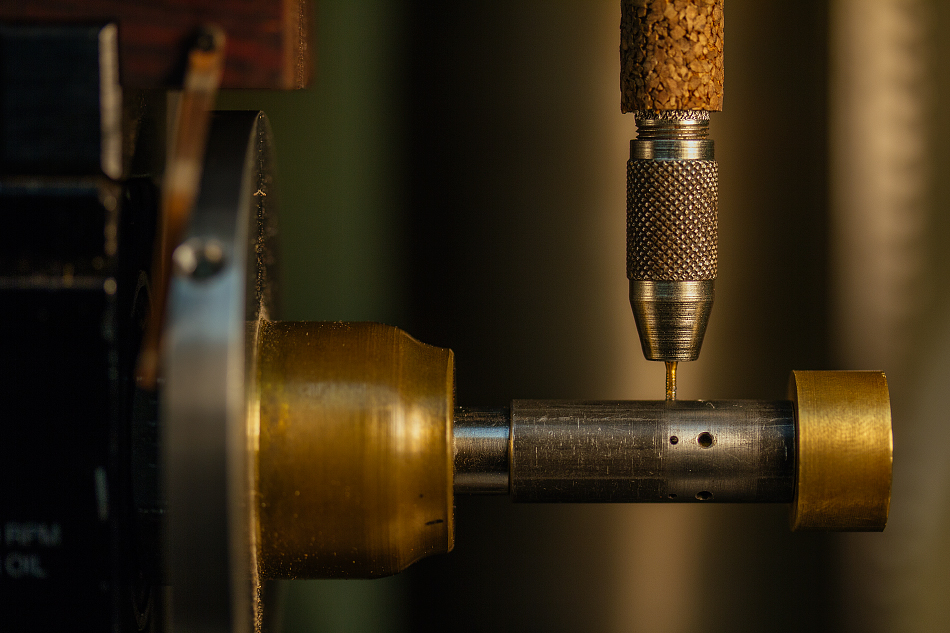

First drilling the holes for the 00-90 screws. The hole is drilled through the bronze spring and the steel at the same time so that when everything goes back together again both holes will line up perfectly.

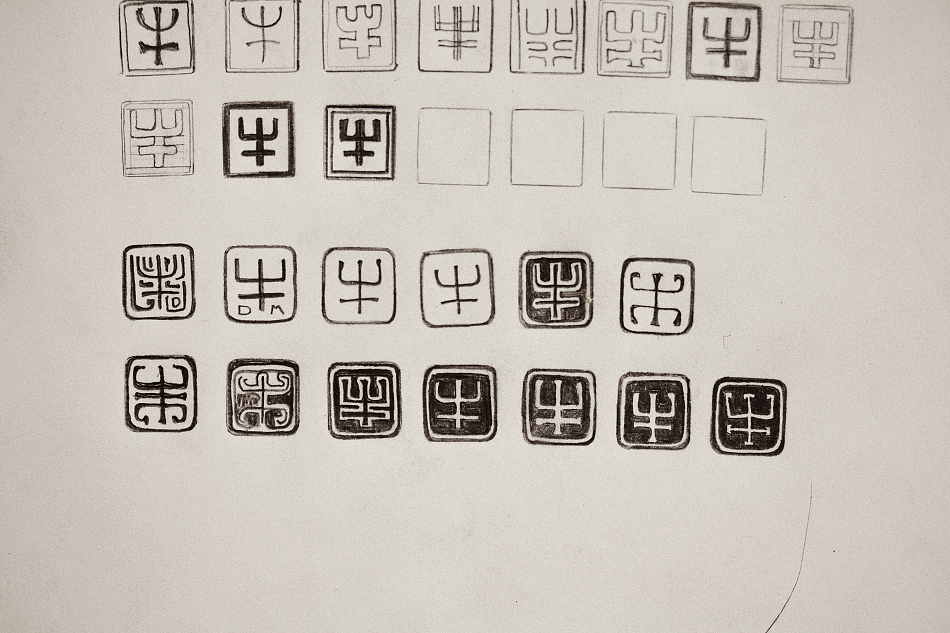

All of the springs are matched to a single pair of holes on the steel tips. So I use this numbered grid to keep track of where they go. Dropping this pad of paper on the floor at this point would be a huge pain in the ass! I set it aside

very carefully. hahah.

Each one of those tiny holes were enlarged with a custom reamer to the perfect clearance hole size for the 00-90 screw.

And here is the tap that I use to cut the screw threads. Of course, this $50 tap broke on me..not even half way through the job.

But, luckily I have this tool-post grinder and was able to re-grind a new point on the tap. I swear it was cutting better than new after that!

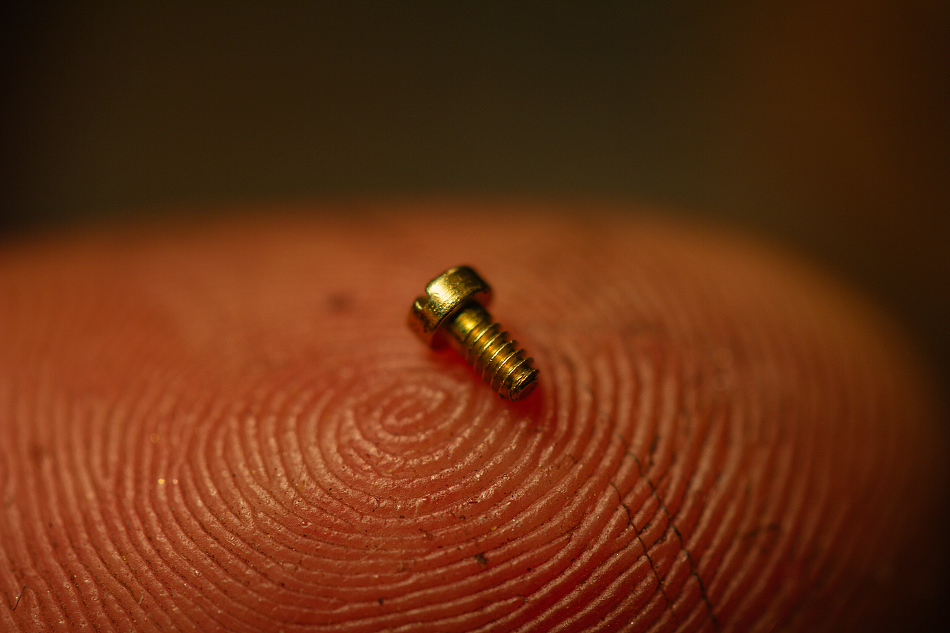

Now that's a small screw!

The cork wrapped pin-vice is spun between the fingers while applying downward pressure. With a tap this small in hard steel, you're always riding the line between success and failure, ha.

The all important cutting fluid.

Anyhow. Next step is to re-assemble the pieces, apply the final finish to the steel and then it's onto the stems! Which shouldn't take too long at all.