Calm before the storm.

I do check this thread daily however, so if anyone has any questions, I'm really happy to answer them!

I've spent a little over a month with the production model now, and there are no changes that I would want to make to it, the design feels complete.

Some further observations based on my use...

I have not had to clean it yet, and it tastes/smells very pleasant, faintly like caramel. Though, I have been vaping a lot of tobacco that is "buttered rum" flavored.. so that may have something to do with it, ha.

The verawood inlay that I added to the bamboo stem has turned a darker green now, and looks very nice! Still smells like lemons... a very cool feature of verawood!

The case is great!

The mouthpiece holds up really well, no dents from my teeth thanks to the extreme hardness of african blackwood.

A note about the power source:

There needs to be a decent seal between the charcoal and the metal tip... it doesn't have to be perfect, but there should be no large air gaps.

Many charcoals will fit just fine right into the tip without modification, but since bamboo is rarely perfectly round, and there will be a slight deviation in diameter between each charcoal.. some pieces will need to be shaped to make a good seal against the end of the metal tip. This involves holding a piece of sandpaper between your fingers, and spinning the charcoal between it, takes a few seconds per charcoal. I thought about adding a little cone shaped pencil sharpener...thing, lined with sandpaper, to shape the tips of the charcoals... but in practice, the sandpaper-only method is so quick and easy that it doesn't seem necessary. A tiny piece of sandpaper should last a very long time.

The next step in preparing the charcoal is to poke air holes into the sides with the poker tool that will come with each okin. If you're vaping indoors, I find that two rows of holes are best, for maximum airflow around the burning ember. If you are vaping outdoors without wind, one row of holes.. and if it's windy, you may not want to poke any holes into the charcoal at all. The holes allow the charcoals to burn more evenly on the outside surface.

You can see the holes that I have poked into the charcoals in this photo,

These holes tend to make the charcoals burn more evenly and completely, and help to customize your experience based on wind conditions and burn preferences.

In practice it's less than 15 seconds of prep time per charcoal, and of course, the best thing to do is prepare all of your charcoals before loading the case with them, so they are ready to go. I actually like prepping the charcoals.. you can play around with the hole pattern, and when you've got that perfect charcoal loaded, it definitely gives you that satisfied feeling that you may get from rolling.

So that's that. Hope it gives you a better idea of what to expect!

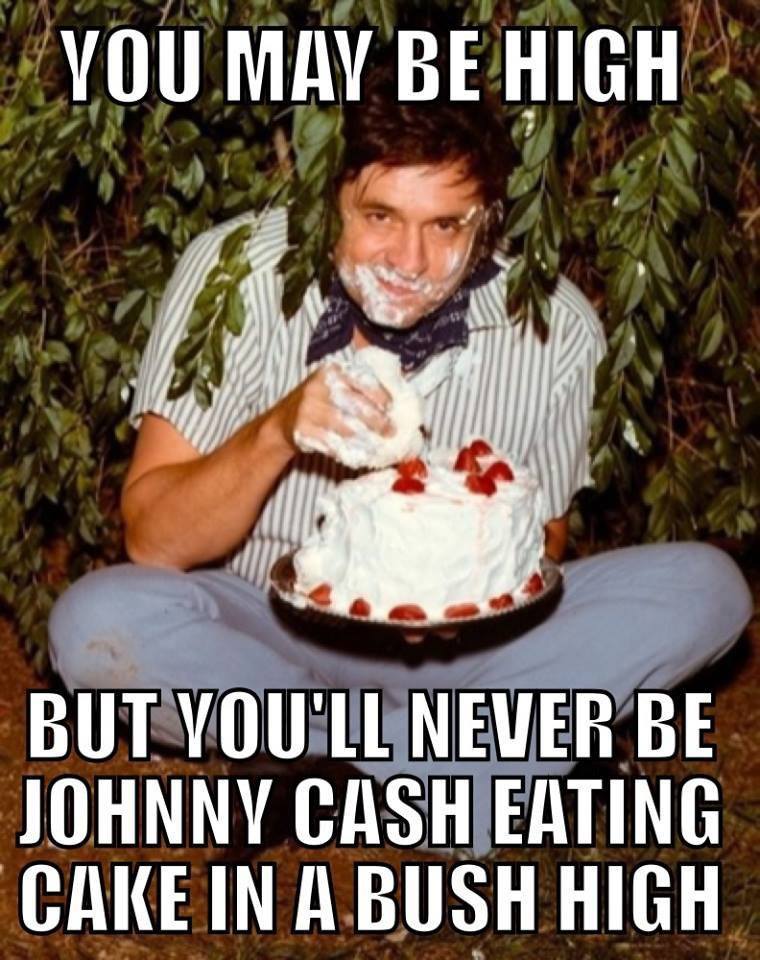

Reminds me of this classic:

Reminds me of this classic:

Both do funny things to my pants

Both do funny things to my pants

Wha hey!

Wha hey!