fubar

Ancient and opiniated inhaler

tl;dr People's opinions about the importance of conduction vs convection in various vaporisers tend to be strongly held although I know of almost no empirical data. I've set up my own simple test bed for measuring temperature in my air/solo stems to help figure out what is really going on as best I can in an empirical, reproducible and scientific way.

Starting with an older model Solo with a power adapter to minimise variation between runs from battery state, running at heat setting #4. Plan to test my Air and EQ as time permits.

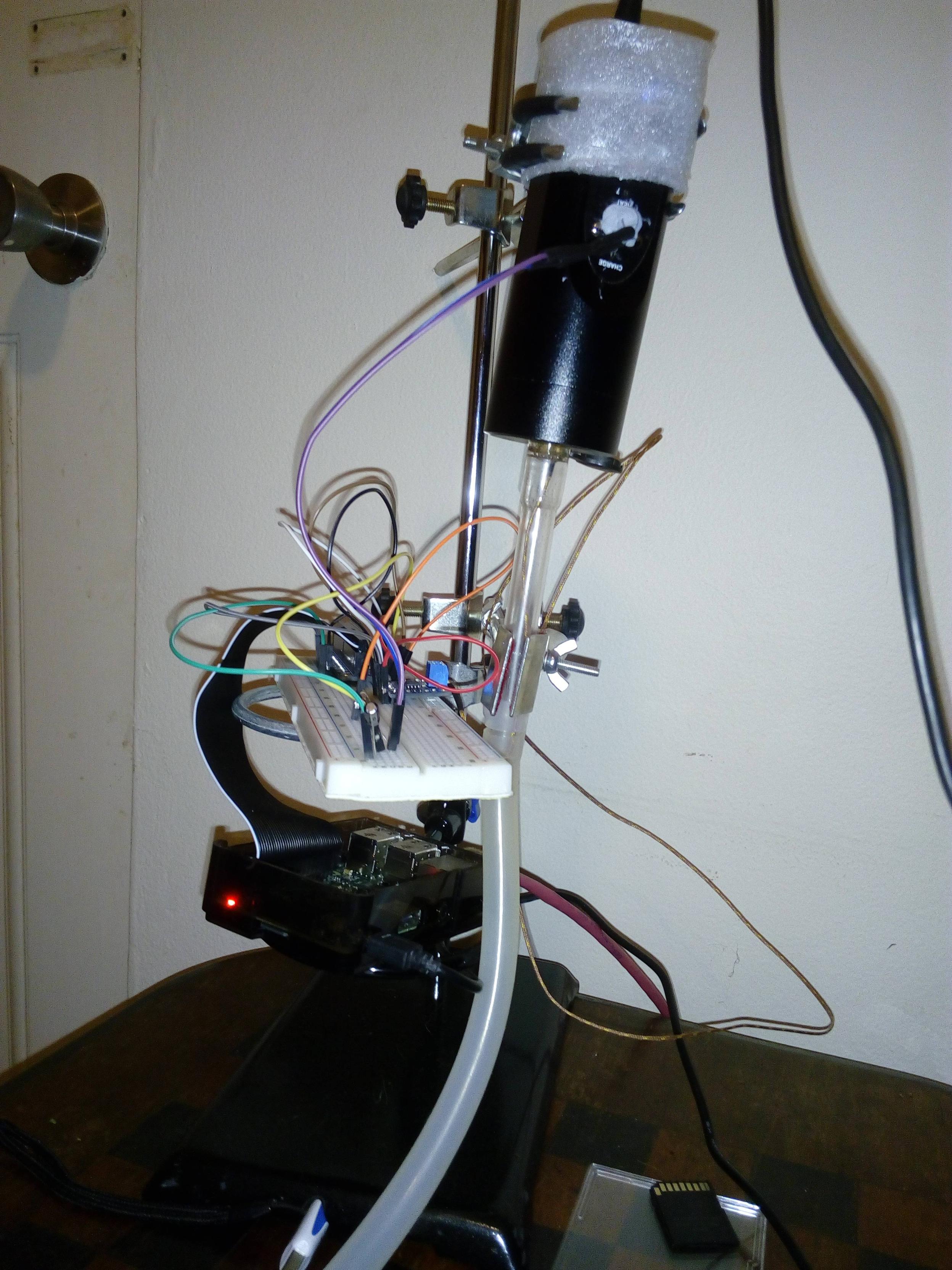

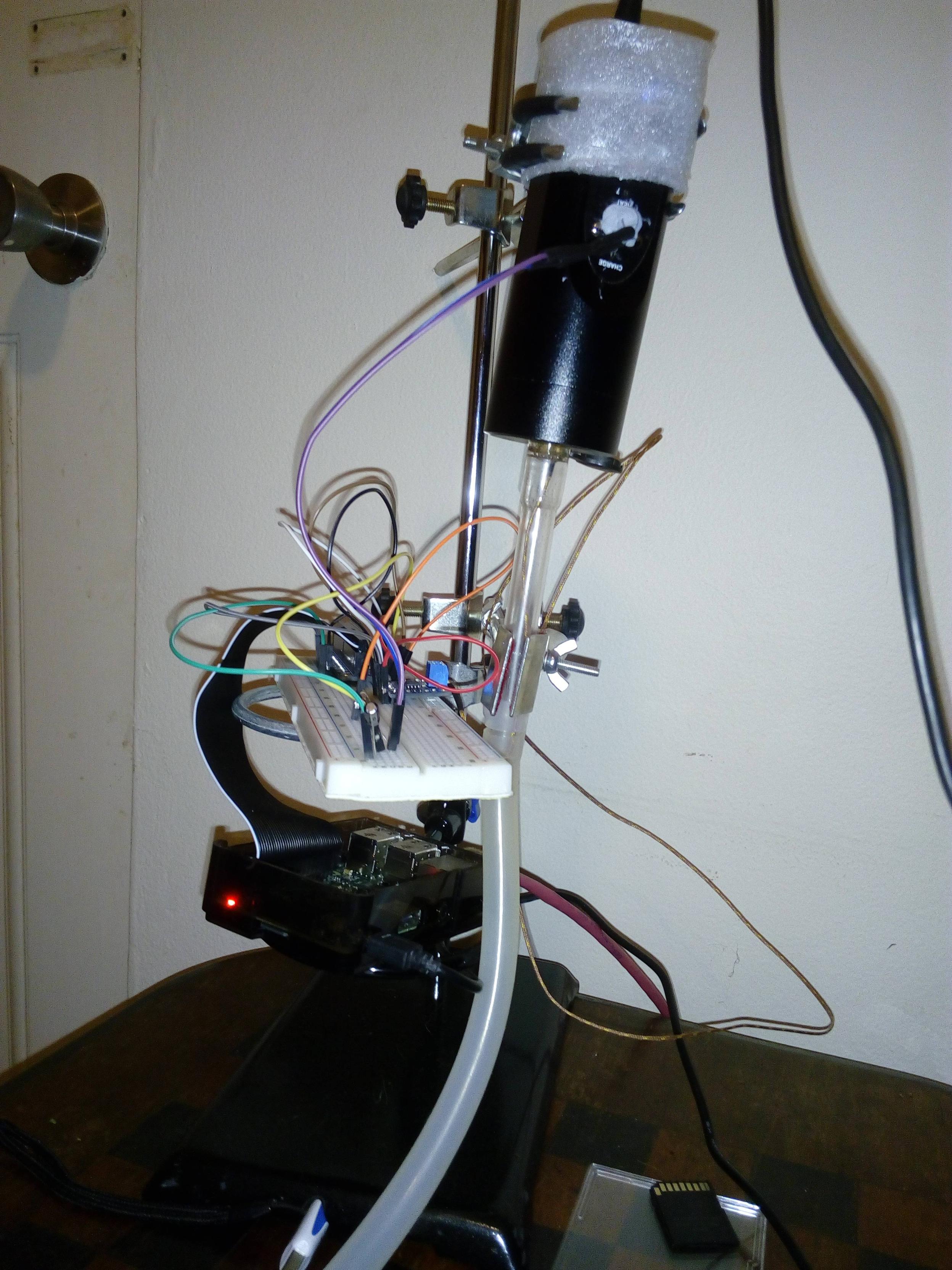

Sensors are a cheap thermocouple in the middle of a stem packed with ABV to measure load temperature as best I can, and a photoresistor to record heater light activity in real time interfaced to the GPIO of a raspberry pi where data are plotted and saved. Program is python interfaced through the adafruit_gpio library and setup as shown in the examples if you look at the photoresistor and k3 thermocouple in the shop on the adafruit site. (no, I'm not affiliated - just a happy customer)

Goal is to empirically distinguish the effects of convection from radiation/conduction without convection by recording temperatures in some ABV over time, using inhalation to add convection to the heat flow to see how the temperature changes...

The pi is at the bottom with the GPIO bus connected to the breadboard where the photoresistor and thermocouple are set up. The Solo (or air) is mounted UPSIDE DOWN to minimise convection so unless someone's inhaling on the silicone tube, heat gets to the thermocouple in the ABV inside the stem mostly via radiation and conduction. The stem is about half way in - see below for the effect stem depth appears to have.

A photoresistor is mounted over the heater light using blu-tac (!) which works pretty well. The thermocouple is up in the stem packed with ABV and the delicate cable runs down the inside of the stem to a loop at the bottom held in place with a silicon sleeve so the cable doesn't wiggle - the sleeve is just above the whip and the cable is looped from inside the stem out and up behind.

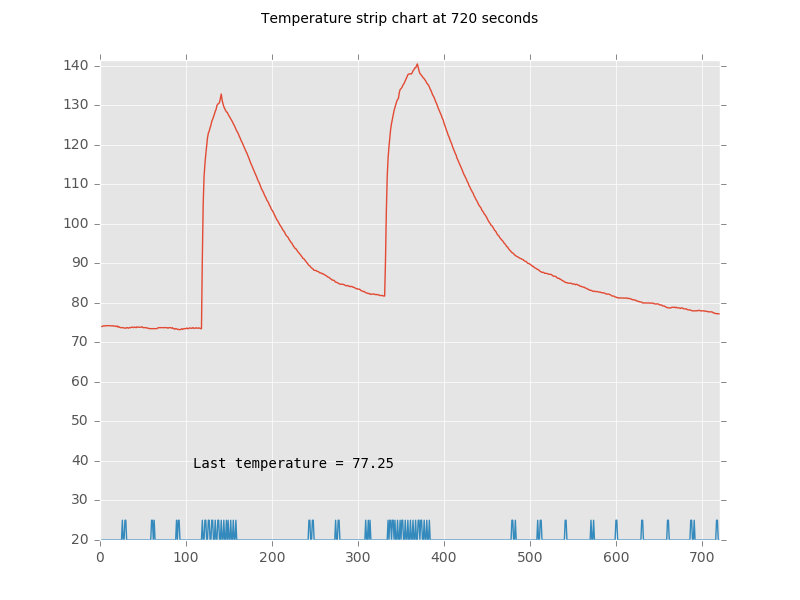

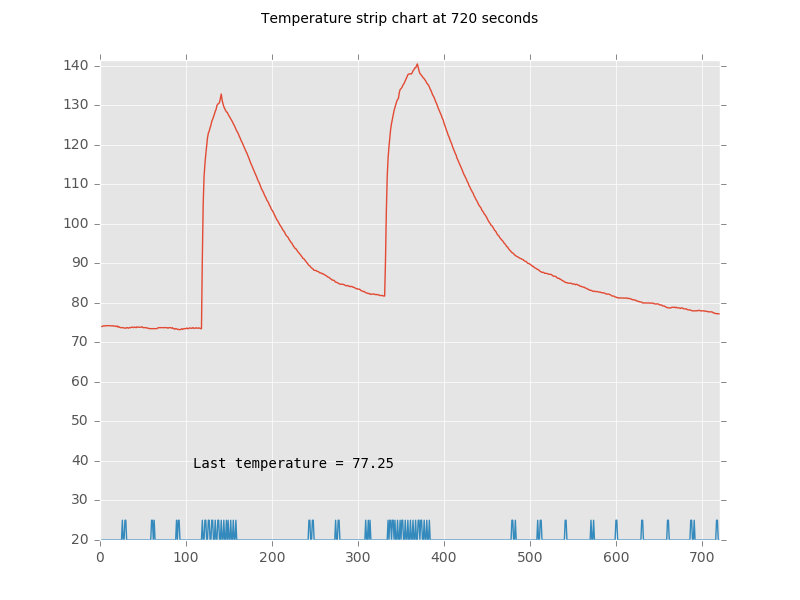

Here's a sample output temperature strip chart.

For the record, I've tested three stem insertion depths and it seems to make a huge difference to the steady state (radiation/conduction heat in vs heat loss) temperature in the load when you are "heat soaking". It's *much* hotter at steady state when pushed right in close to the oven (about 150C) and much cooler when almost out (60-65).

In the above run, the stem was about half way between falling out and pushed in as far as it will go and steady state temperature had more or less already been reached earlier before I restarted a run - it was about 75C.

Heater cycling is illustrated crudely in the bottom blue lines - where it's 20, that means no blinking. You can see how the heater seems to be relaxed and cycling without the temperature moving much at the start when as a result of a previous run, the setup was pretty much heat soaked and at a reasonably steady state, probably well below the Solo oven set point temperature.

It's easy to see where the 2 inhalations happened. The temperature immediately starts rising rapidly and the heater starts cycling as expected to try to keep up.

Interesting to see how fast and how much the temperature rises above "heat soak" conduction/radiation vs heat loss steady state immediately the inhalation starts and convection (heat transfer in hot air from the oven) kicks in.

Aside from Solo temperature setting (4 above) it seems that the effect of heat soaking (ie the steady state temperature achieved when you leave a loaded stem in while the solo is running) depends largely on stem insertion depth.

Mid insertion will reach a more or less steady state around 80C so very little material will vaporise when only radiation and conduction can heat the load. Once convection kicks in, the temperature rises quickly to more effective levels to help release volatiles.

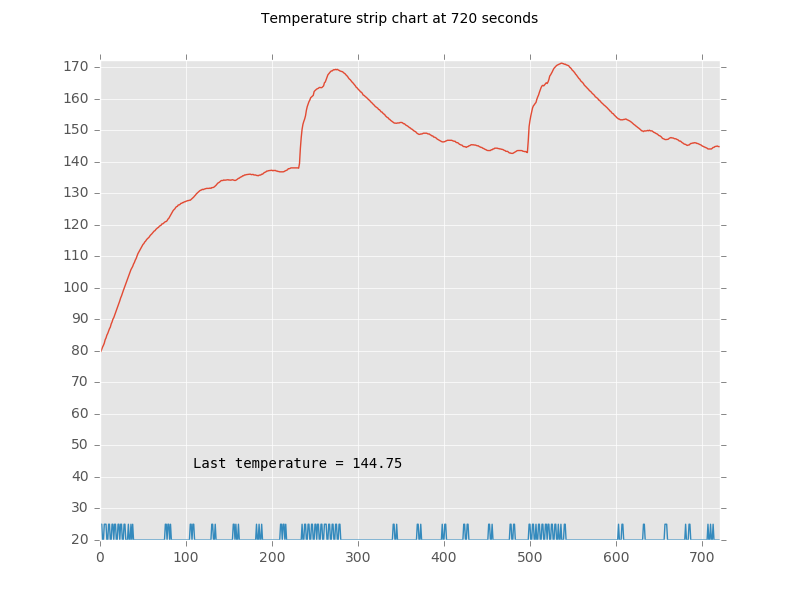

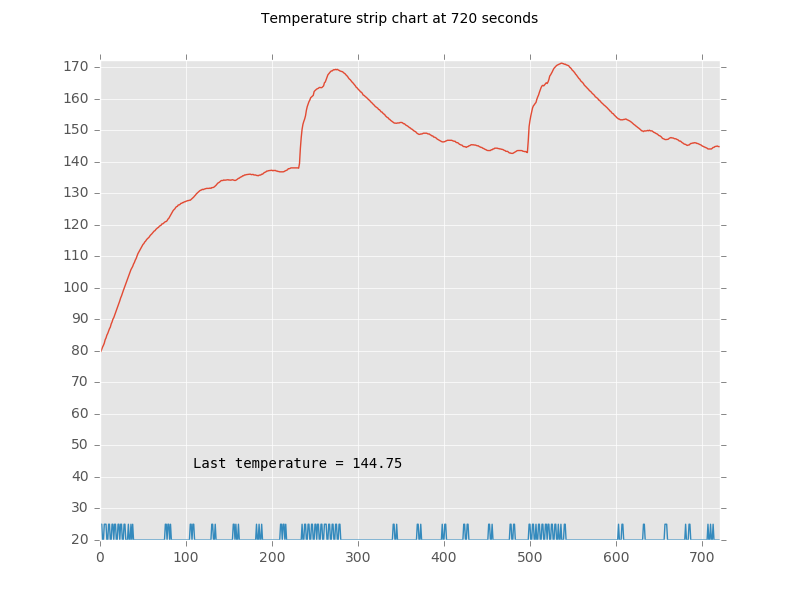

Pushing the stem right down and backing off a fraction of a mm to avoid blocking the oven holes) results in much higher temperatures than shallow or mid insertion as shown in the plot below with the stem right in which settles at nearly 140C at the same Solo setting of 4 as above! Looks like much less heat loss at steady state probably because much more of the load and the thermocouple itself is down inside the Solo, so not losing as much heat to room air as when the stem is raised half way out like above.

More to come! Meanwhile, feel free to draw your own conclusion about whether it makes sense to call the solo a mostly conduction or convection vaporiser - clearly both happen but without convection, the load doesn't seem to get hot enough to vaporise much without inhalation (convection) unless the stem has been pushed deep in so the load is right near the oven so radiation from hot stainless steel will be an effective heat transfer mechanism. More to follow - I'll post other experiments as I go.

Starting with an older model Solo with a power adapter to minimise variation between runs from battery state, running at heat setting #4. Plan to test my Air and EQ as time permits.

Sensors are a cheap thermocouple in the middle of a stem packed with ABV to measure load temperature as best I can, and a photoresistor to record heater light activity in real time interfaced to the GPIO of a raspberry pi where data are plotted and saved. Program is python interfaced through the adafruit_gpio library and setup as shown in the examples if you look at the photoresistor and k3 thermocouple in the shop on the adafruit site. (no, I'm not affiliated - just a happy customer)

Goal is to empirically distinguish the effects of convection from radiation/conduction without convection by recording temperatures in some ABV over time, using inhalation to add convection to the heat flow to see how the temperature changes...

The pi is at the bottom with the GPIO bus connected to the breadboard where the photoresistor and thermocouple are set up. The Solo (or air) is mounted UPSIDE DOWN to minimise convection so unless someone's inhaling on the silicone tube, heat gets to the thermocouple in the ABV inside the stem mostly via radiation and conduction. The stem is about half way in - see below for the effect stem depth appears to have.

A photoresistor is mounted over the heater light using blu-tac (!) which works pretty well. The thermocouple is up in the stem packed with ABV and the delicate cable runs down the inside of the stem to a loop at the bottom held in place with a silicon sleeve so the cable doesn't wiggle - the sleeve is just above the whip and the cable is looped from inside the stem out and up behind.

Here's a sample output temperature strip chart.

For the record, I've tested three stem insertion depths and it seems to make a huge difference to the steady state (radiation/conduction heat in vs heat loss) temperature in the load when you are "heat soaking". It's *much* hotter at steady state when pushed right in close to the oven (about 150C) and much cooler when almost out (60-65).

In the above run, the stem was about half way between falling out and pushed in as far as it will go and steady state temperature had more or less already been reached earlier before I restarted a run - it was about 75C.

Heater cycling is illustrated crudely in the bottom blue lines - where it's 20, that means no blinking. You can see how the heater seems to be relaxed and cycling without the temperature moving much at the start when as a result of a previous run, the setup was pretty much heat soaked and at a reasonably steady state, probably well below the Solo oven set point temperature.

It's easy to see where the 2 inhalations happened. The temperature immediately starts rising rapidly and the heater starts cycling as expected to try to keep up.

Interesting to see how fast and how much the temperature rises above "heat soak" conduction/radiation vs heat loss steady state immediately the inhalation starts and convection (heat transfer in hot air from the oven) kicks in.

Aside from Solo temperature setting (4 above) it seems that the effect of heat soaking (ie the steady state temperature achieved when you leave a loaded stem in while the solo is running) depends largely on stem insertion depth.

Mid insertion will reach a more or less steady state around 80C so very little material will vaporise when only radiation and conduction can heat the load. Once convection kicks in, the temperature rises quickly to more effective levels to help release volatiles.

Pushing the stem right down and backing off a fraction of a mm to avoid blocking the oven holes) results in much higher temperatures than shallow or mid insertion as shown in the plot below with the stem right in which settles at nearly 140C at the same Solo setting of 4 as above! Looks like much less heat loss at steady state probably because much more of the load and the thermocouple itself is down inside the Solo, so not losing as much heat to room air as when the stem is raised half way out like above.

More to come! Meanwhile, feel free to draw your own conclusion about whether it makes sense to call the solo a mostly conduction or convection vaporiser - clearly both happen but without convection, the load doesn't seem to get hot enough to vaporise much without inhalation (convection) unless the stem has been pushed deep in so the load is right near the oven so radiation from hot stainless steel will be an effective heat transfer mechanism. More to follow - I'll post other experiments as I go.

Last edited: