I had some screens that were just a tiny bit small in diameter. I thought if I hammered it flatter, it would also get bigger in diameter. It worked great. The fit was very nice. The screen is a lot stiffer.

The surface of the screen was now very shiny and more of a weave than a screen. The holes between the wires are still the same size so the airflow is not affected. I also noticed that plant material wasn't sticking to the shiny screen and it stays very clean all the time.

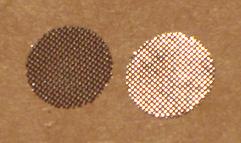

The two screens in the photo are identical. The one on the right has been hammered smooth.

A smooth anvil would be ideal for making them, but 2 hammers will also work. Just use one of the hammers as an anvil.

Has anyone else ever tried this?

The surface of the screen was now very shiny and more of a weave than a screen. The holes between the wires are still the same size so the airflow is not affected. I also noticed that plant material wasn't sticking to the shiny screen and it stays very clean all the time.

The two screens in the photo are identical. The one on the right has been hammered smooth.

A smooth anvil would be ideal for making them, but 2 hammers will also work. Just use one of the hammers as an anvil.

Has anyone else ever tried this?

we do it to our heads all the time..

we do it to our heads all the time..