On the subject of restoring air flow through the screen at the bottom of the chamber, here's what DOESN'T work.

Even though my airflow wasn't all that bad, it had slowed some and I really wanted to avoid taking it apart. It occurred to me that if I:

(1) block off (with tape) all the air intake holes except the holes on one side;

(2) turn the unit upside down and repeatedly hit the chamber screen with an ISO-drenched qtip (for like a full minute) in the hopes of liquifying the debris;

(3) turn it right side up (to encourage the ISO to pass to the other side of the screen) and apply a damp (not dripping) qtip;

(4) then while it's wet, blow really hard through the air intake holes to sort of backflush the reside on the screen (both using just my mouth and then with compressed computer-cleaning air,

--- then, maybe this would blast out the tiny holes and all would be good without disassembly!

Well, as it turned out, this just made it WORSE! It seems the excess ISO probably turned the screen debris into sticky goo. I turned on the heat with an empty bowl and sucked for all my might, and this actually helped a little, but all-in-all this was a bad idea. Hopefully you can learn from my mistake!

On a slightly different point, I had earlier suggested running a needle into the holes to open them up. I can see now why this doesn't work: the holes are so tiny that even a needle won't fit! I suspect anything fine enough to fit (like super fine wire) would probably be so fine that it would bend with the slightest resistance. So it looks like I'll be taking this sucker apart after all

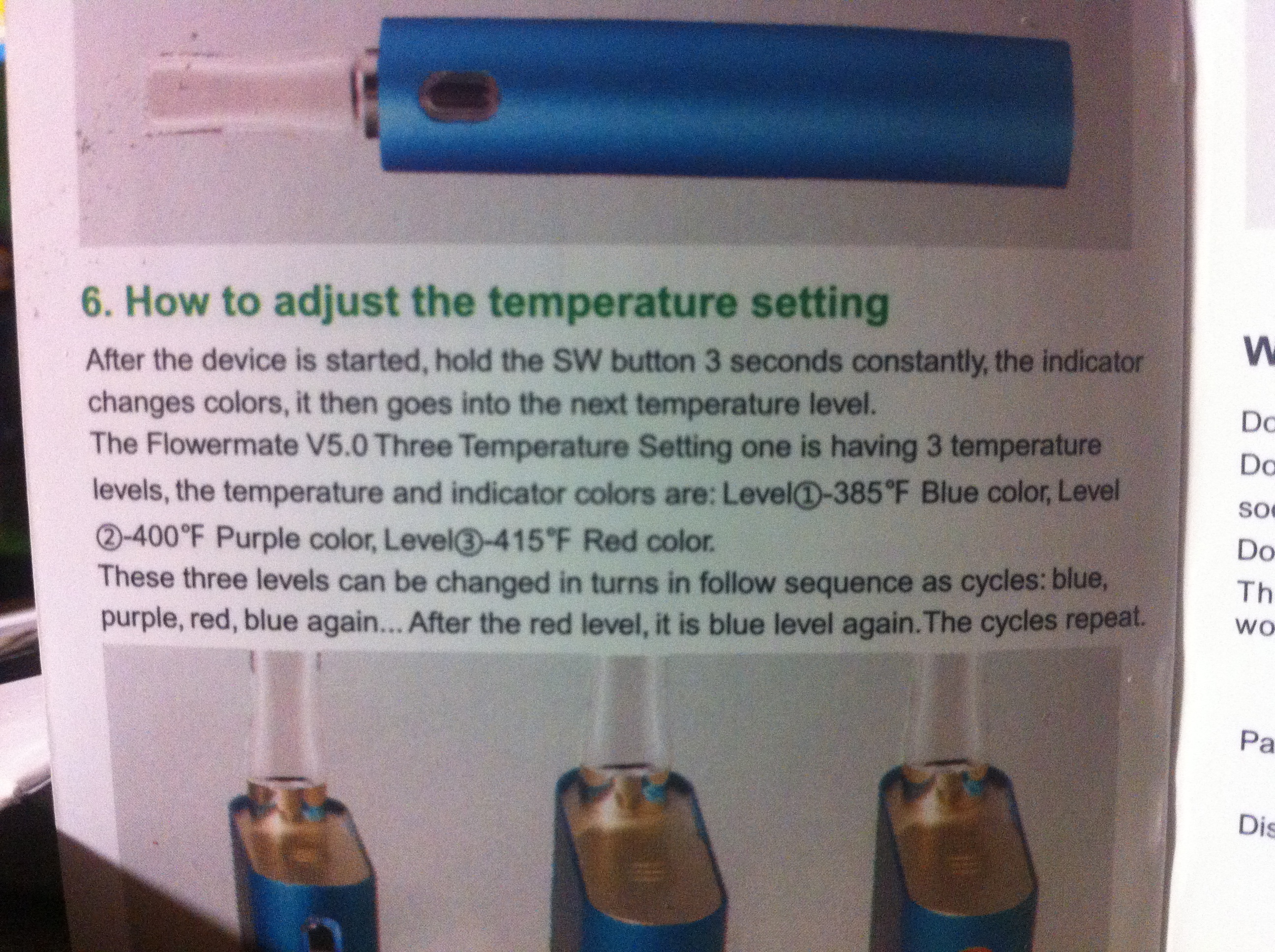

) to have one 3 temp version (current full sized model) with an 'S' and the 3 temp mini without it. As Kero has stated more than once, Smiss is very much willing to listen to feedback and make changes, so that's a plus.

) to have one 3 temp version (current full sized model) with an 'S' and the 3 temp mini without it. As Kero has stated more than once, Smiss is very much willing to listen to feedback and make changes, so that's a plus.