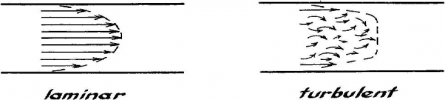

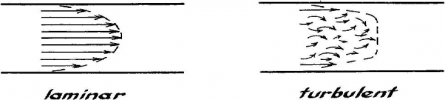

It's important to make some definitions clear. Laminar and turbulent are both ways of characterizing flow regimes/patterns.

Laminar Flow: This is flow that is characterized by smooth streamlines with fluid flowing in parallel layers

Turbulent Flow: This is flow that is characterized by irregular streamlines with fluid layers mixing and chaotic changes in the pressure and flow velocity

The flow type is going to be different in different parts of the vaporizer. You can have turbulent flow through the heater section, but by the time it reaches the herb chamber it could be laminar.

The reason turbulence is often desired in the

heater section is because turbulence causes more contact between the wall of the heater and the air passing through it. This leads to increased heat being transferred from the heater to the air.

In the

herb chamber, I have a suspicion that turbulent flow might be beneficial for even extraction, because with laminar flow the center of the pipe has a higher velocity than the edges, versus turbulent flow leads to a more even velocity profile through the pipe. As shown in this figure depicting the average velocity profile in a pipe's cross section:

There is a layer of air surrounding the walls called the

boundary layer. As

@west-elec points out, with laminar flow the velocity at the boundary is zero due to the "no slip boundary condition". Turbulent flow is able to overcome this condition, which is the reason there is more contact with the walls with turbulent flow, and also the reason the average velocity profile is more even with turbulent flow (shown in above figure).

To your point about statement

"the Elev8r has a similar 'laminar flow' number, as the Supreme..." I think this is a major oversimplification. The number I imagine they are referring to here is the Reynold's number. But this is only useful for comparing different parts of the vaporizer, since any vaporizer will have a different Reynold's numbers at different places along the airflow. So in reality comparing the Reynold's numbers between vaporizers provides no real useful data, since every design is different. Even if you compare the Reynold's number within the heaters of two vaporizers, that number will vary widely at different positions in the heater.

The red circle with blue dots is also an incredibly misleading figure, that is of very little value. The reason this is of little value is because airflow does not behave like that, in fact it almost behaves the opposite way with laminar flow. Air heated at the walls of the pipe does not stay at the walls. If you were to heat a straight pipe and draw air through it (while maintaining laminar flow), the center of the pipe would have the hot air, not the edges. In fact, since this is supposed to be representative of laminar flow, it would probably be the edges where the air was the least hot due to the no slip condition.

I agree with idea that turbulent flow is beneficial in the heater section to maximize efficiency, but this way of presenting the information seems poor.

To claim that a certain flow type is unique to one vaporizer seems to me to be an obvious oversimplification for the sake of marketing. There are certainly unique benefits of the Supreme's heat exchanger, but it is definitely not the only vaporizer to take advantage of this principle.

]

]