iScrtAznMan

New Member

I had a discussion thread that stopped being a discussion, so I'm restarting as DIY:

If there's interest I don't mind to share my code, however it's still pretty rough and I would like to clean it up a bit more before sharing. I believe making it public is the best way for it to improve (a lot of you know more than I do), but I don't want to be associated with the mess it is now. It's also not too hard to build it from scratch if you know what you're doing. It just ends up taking me forever because I'm normally doing some manually verification testing, if you know what I mean.

The way I have it setup currently is with the Adafruit Max 31856 TC amplifier, 2 IRLZ44s, a TC4428 to drive the mosfet for the log, and a bunch of pull down resistors. I'm using a K-type thermocouple that you can also get off Adafruit shoved against the heater, but I'm trying to get something better. I coded everything in Python, but will probably make a pretty webapp for the client once I finish the controller logic. Currently the client is also in python and it's all over UDP. It's not super complicated but I spent a lot of time reading about why my mosfets got hot (just spend the $1 on an IC to do . . . ). I'm running the mosfets right now at 50kHz and have no issues at 35V which pulls 1.745A or 61.59W. If I got rid of the terrible Circuit Python libraries, I could probably go higher but there's not much point. At idle it pulls around 4W.

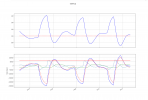

The biggest limit right now is the TC lag (the amplifier takes somewhere around 50ms-100ms to do the analog conversion) and the fact that my TC is touching the heater and outer wall. The Omega TC I got are unsheathed and I need to figure out how to insulate them (most likely switch to a glass heater). It currently has about 5-10s of lag. 5 seconds during a hit with Tu around 13s (distance between oscillations at Ku for Ziegler-Nichols tuning). This makes Kd pretty important to help kickstart and stop the heater. At my draw rate, I notice a 20C temp swing that seems pretty constant. Without preheating, it drops 20C. It also will overshoot 20C once you stop drawing if you are at the setpoint. It's probably possible to find a pattern and implement a stead state error when idle, but just increasing the airpath distance on the heater is better. Maybe just steal an old volcano heater if you can find one cheap. I want to DIY something smaller though. Maybe a U-pipe.

Is it cost effective? Probably not, but if you only buy the parts you need you could probably do it for $50 if you already have a variable DC Power Supply (or if you have a laptop power supply). Lower if you feel comfortable building your own TC amplifier. Or you could just go buy a box mod . . . Is it safe? Probably not but I'm trying to get it as safe as possible. I don't feel comfortable leaving it on unattended but it also takes like 30s to heat up. However, I do see a lot of room to play and improve the system. The biggest reason I'm doing this is so I can customize however I want because I have the code and most vapes have shit code that can't really be modified or it's all closed sourced and you have no way to trust it. Pretty sure some of you out there are smarter than me and could make improvements.

Anyone try adding thermometers to log vapes?

Just curious if anyone else has done or thought of doing this? I feel like it wouldn't be too hard to add a temp probe to the basket screens to get temps of outcoming vapor to add another variable to manipulate. I've been looking at thermocouples used for ovens, but those probably have too much...

fuckcombustion.com

If there's interest I don't mind to share my code, however it's still pretty rough and I would like to clean it up a bit more before sharing. I believe making it public is the best way for it to improve (a lot of you know more than I do), but I don't want to be associated with the mess it is now. It's also not too hard to build it from scratch if you know what you're doing. It just ends up taking me forever because I'm normally doing some manually verification testing, if you know what I mean.

The way I have it setup currently is with the Adafruit Max 31856 TC amplifier, 2 IRLZ44s, a TC4428 to drive the mosfet for the log, and a bunch of pull down resistors. I'm using a K-type thermocouple that you can also get off Adafruit shoved against the heater, but I'm trying to get something better. I coded everything in Python, but will probably make a pretty webapp for the client once I finish the controller logic. Currently the client is also in python and it's all over UDP. It's not super complicated but I spent a lot of time reading about why my mosfets got hot (just spend the $1 on an IC to do . . . ). I'm running the mosfets right now at 50kHz and have no issues at 35V which pulls 1.745A or 61.59W. If I got rid of the terrible Circuit Python libraries, I could probably go higher but there's not much point. At idle it pulls around 4W.

The biggest limit right now is the TC lag (the amplifier takes somewhere around 50ms-100ms to do the analog conversion) and the fact that my TC is touching the heater and outer wall. The Omega TC I got are unsheathed and I need to figure out how to insulate them (most likely switch to a glass heater). It currently has about 5-10s of lag. 5 seconds during a hit with Tu around 13s (distance between oscillations at Ku for Ziegler-Nichols tuning). This makes Kd pretty important to help kickstart and stop the heater. At my draw rate, I notice a 20C temp swing that seems pretty constant. Without preheating, it drops 20C. It also will overshoot 20C once you stop drawing if you are at the setpoint. It's probably possible to find a pattern and implement a stead state error when idle, but just increasing the airpath distance on the heater is better. Maybe just steal an old volcano heater if you can find one cheap. I want to DIY something smaller though. Maybe a U-pipe.

Is it cost effective? Probably not, but if you only buy the parts you need you could probably do it for $50 if you already have a variable DC Power Supply (or if you have a laptop power supply). Lower if you feel comfortable building your own TC amplifier. Or you could just go buy a box mod . . . Is it safe? Probably not but I'm trying to get it as safe as possible. I don't feel comfortable leaving it on unattended but it also takes like 30s to heat up. However, I do see a lot of room to play and improve the system. The biggest reason I'm doing this is so I can customize however I want because I have the code and most vapes have shit code that can't really be modified or it's all closed sourced and you have no way to trust it. Pretty sure some of you out there are smarter than me and could make improvements.

Last edited:

, i suggest you take a look at those,but IMO ,in some builds it would be batter to control the temp based on resistance curve (Check RTD temp sensors). Another great source would be the Bud Toaster thread,now Herb Cube by

, i suggest you take a look at those,but IMO ,in some builds it would be batter to control the temp based on resistance curve (Check RTD temp sensors). Another great source would be the Bud Toaster thread,now Herb Cube by