HI everyone, someone else recently posted their home made concentrates dabber, and that is what brought me here. I've been putting in some work to make my own dabber after purchasing a few wax/oil carts that have failed. First one I bought was the Micro G-pen Vape and after a bunch of wasted oil i never was able to get any really good hits from it. I then found the gentlemens V2 cart for 510 and wow it worked, but only for a few days then caput! In taking apart the V2 I found that (In my opinion) the solderless design implemented was the failing point of the system. The Kanthal wire was also weak IMO.. and was "hooked" to their solid core wire, and if the connection wasn't tight, you'd lose the ability to get current through. I went through 5 Gentlmens V2 carts in less than 2 weeks. 4 of them were done in just a few days, and the last miracle one I barely used trying to keep it alive until it died. There were also a few other issues i didnt' like, such as filling. I hated how you had to be so precise with the loading.. if you got it onto the inner walls you'd have to heat it up and drip it down. Then it would hit the Nickel mesh and never really get much onto the coils. So with all this is mind, I modeled my project after the V2 with a few personal twists.

So on the hunt I began for ceramic cups and Kanthal wire. After some research I decided on 32AWG Kanthal, and I was re-using 3 of the ceramic cups from the V2 until I found the last of some ceramic cups online. (If anyone knows where to get ceramic cups please pm me)

My first 1-2 versions worked great. I was testing between 5-8 wraps of different diameter into these cups. One of my versions lasted over 1 month before I killed it with harsh cleaning (burnt oil caked onto the coils).

I then started to try and innovate a dual coil system, where 2 coils were connected both on the power and ground sides but separated inside the cup in the shape of a circle. So when it was lit, it looked like a car cig lighter. I could then scrape oils onto the inner side of the SS sleeve, and then melt it down the sides directly on the coils, not the nickel mesh. Here's a vid of the ONLY time this cart worked. It then crapped out on me and I was never able to get it working again.

As you can see, the coils are lit up along the inner circle of the SS Sleeve. But after numerous attempts to finish a working version i finally gave up and went back to a single coil.

My latest cart, has been working for 4 days. I've used about .5G of oil so far in it. Its showing small signs of burnt oil. I use a Lavatube and have been using it on 4.5V. I havent needed to keep pressing the on button once on this cart. The hits are big enough to make you cough, and its so easy to load, you just dab right into the ceramic cup which houses the coil. I snapped a few pics of my last build. I built 4 of these in 2 hours. I'm not that good at write ups, or explaining things.. I'm no electrician so I'm probably doing plenty wrong.

Starting off with: 2 SS Sleeves and 510 bettery connectors taken off my Ecig Cartomizer (I cut one shorter for testing), 32AWG Kanthal, 2 ceramic cups. And of course a soldering iron with solder, and jewelers screwdrivers to make the coils.

Pic with ceramic cups reversed

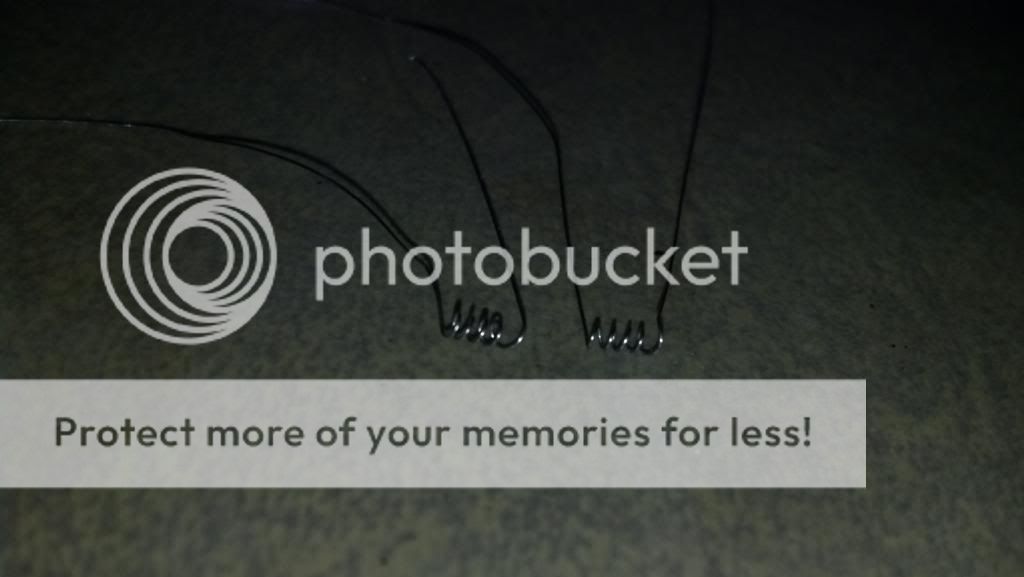

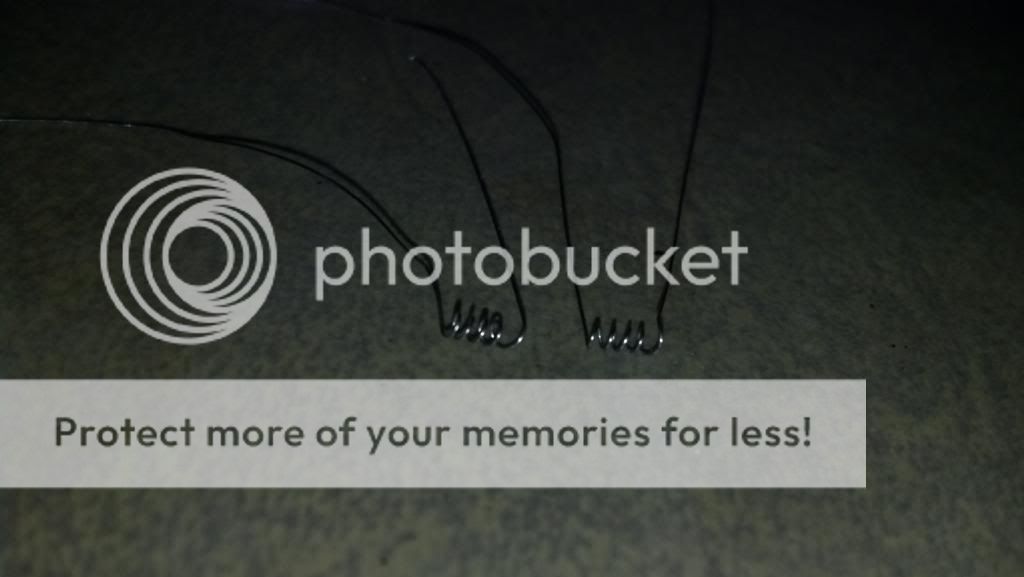

Then I twisted my Kanthal wire around my smallest jewelers SD 5 wraps each. I left one side shorter then the other (Explanation later)

I then folded up some Alum foil to use as insulation for the ceramic cups, and to provide a wedge for the ceramic cups to side inside without flopping around. I pre-wrapped the alum foil then removed it just so its coiled right. I didnt want to have to wrap it around afterwrards when everything is connected in fears that the excess movement would damage something. You have to play with the right amount of alum foil to properly fit the inside of the SS sleeve. Too little and the cup and wires will wiggle and probably fail early, too much and it wont fit.

You cant see from the pix, but theres 2 small holes inside the cup where the coils fit through, here's that it looks like from the front with the coils in. Sorry for the blurry pic

Now i have no pix of the rest of the build, but i Soldered the short side of the coil to the inner post of the battery connector. Then wrapped the alum foil around the cup again tight. I didnt solder the side that goes to ground because i couldnt get it to stick right. So i just left it hanging down the outside of the battery connecter, then slid the sleeve over everything and then pinched the ground wire into place between the sleeve and the grooved parts of the battery connector. I then cut away the excess. The result looks like this. Sorry blurry pix (it was at night in the darkness w/ headlamp as not to wake up the wifey)

And here is the vid of the cart in action

Now, all i need to do is heat drop a small dab directly into the cup, onto the coil. Its so close to the top of the car that its hard to miss and get along the sides/waste. One drop = .05-.1Gram and gives me about 4-5 hits. 2-3 hits before the taste changes, then a new drop for a fresh hit and taste.

**NO.. i am NOT selling these. I'm posting just to help others out**

Looking for constructive feedback please. Also, looking for a good source for inexpensive nickel mesh foil. Also looking for a source of ceramic cups like these or other styles that might work.

Thanks for reading!

-J

So on the hunt I began for ceramic cups and Kanthal wire. After some research I decided on 32AWG Kanthal, and I was re-using 3 of the ceramic cups from the V2 until I found the last of some ceramic cups online. (If anyone knows where to get ceramic cups please pm me)

My first 1-2 versions worked great. I was testing between 5-8 wraps of different diameter into these cups. One of my versions lasted over 1 month before I killed it with harsh cleaning (burnt oil caked onto the coils).

I then started to try and innovate a dual coil system, where 2 coils were connected both on the power and ground sides but separated inside the cup in the shape of a circle. So when it was lit, it looked like a car cig lighter. I could then scrape oils onto the inner side of the SS sleeve, and then melt it down the sides directly on the coils, not the nickel mesh. Here's a vid of the ONLY time this cart worked. It then crapped out on me and I was never able to get it working again.

As you can see, the coils are lit up along the inner circle of the SS Sleeve. But after numerous attempts to finish a working version i finally gave up and went back to a single coil.

My latest cart, has been working for 4 days. I've used about .5G of oil so far in it. Its showing small signs of burnt oil. I use a Lavatube and have been using it on 4.5V. I havent needed to keep pressing the on button once on this cart. The hits are big enough to make you cough, and its so easy to load, you just dab right into the ceramic cup which houses the coil. I snapped a few pics of my last build. I built 4 of these in 2 hours. I'm not that good at write ups, or explaining things.. I'm no electrician so I'm probably doing plenty wrong.

Starting off with: 2 SS Sleeves and 510 bettery connectors taken off my Ecig Cartomizer (I cut one shorter for testing), 32AWG Kanthal, 2 ceramic cups. And of course a soldering iron with solder, and jewelers screwdrivers to make the coils.

Pic with ceramic cups reversed

Then I twisted my Kanthal wire around my smallest jewelers SD 5 wraps each. I left one side shorter then the other (Explanation later)

I then folded up some Alum foil to use as insulation for the ceramic cups, and to provide a wedge for the ceramic cups to side inside without flopping around. I pre-wrapped the alum foil then removed it just so its coiled right. I didnt want to have to wrap it around afterwrards when everything is connected in fears that the excess movement would damage something. You have to play with the right amount of alum foil to properly fit the inside of the SS sleeve. Too little and the cup and wires will wiggle and probably fail early, too much and it wont fit.

You cant see from the pix, but theres 2 small holes inside the cup where the coils fit through, here's that it looks like from the front with the coils in. Sorry for the blurry pic

Now i have no pix of the rest of the build, but i Soldered the short side of the coil to the inner post of the battery connector. Then wrapped the alum foil around the cup again tight. I didnt solder the side that goes to ground because i couldnt get it to stick right. So i just left it hanging down the outside of the battery connecter, then slid the sleeve over everything and then pinched the ground wire into place between the sleeve and the grooved parts of the battery connector. I then cut away the excess. The result looks like this. Sorry blurry pix (it was at night in the darkness w/ headlamp as not to wake up the wifey)

And here is the vid of the cart in action

Now, all i need to do is heat drop a small dab directly into the cup, onto the coil. Its so close to the top of the car that its hard to miss and get along the sides/waste. One drop = .05-.1Gram and gives me about 4-5 hits. 2-3 hits before the taste changes, then a new drop for a fresh hit and taste.

**NO.. i am NOT selling these. I'm posting just to help others out**

Looking for constructive feedback please. Also, looking for a good source for inexpensive nickel mesh foil. Also looking for a source of ceramic cups like these or other styles that might work.

Thanks for reading!

-J

It's very unsafe, man !

It's very unsafe, man !