hi pipes, hi fc

i felt to give some feedback as the bulli really is a game changer for me.

i used to be a log vape user for 2 years, since the beginning of vaping. i always wanted a portable vape to take covection hits, but never saw smth useable. since feb 2016 the bulli got my daily driver, even at home.

i use the v coil setup, now with 0.526 ohm. its really near the limit of what i can put into the heating chamber. for intial "burn" i begin at 100c and increase by 10c until wished temp. these steps in heating avoid an initial red lighting and the coil keeps having nice colors and a nice clean surface. i find the more even the coil is made and the more metal in the heating chamber - the more even the plant matter is heated. no need to stir and in three 15 sec hits a bowl is wasted. w00t!

i used to order the original drip tip adapter, and put a round metal plate with a small 1,2 mm hole just before it. this spray makes the vapor smooth, due to breaking bigger particles into smaller ones - so far the theory. already did this in log vape times.

but i found a better thing. just order a metal vape-liquid tank (edelstahl leerdepot), and cut just before the end,. like seen in the second picture. with two air-intakes sitting opposite to each other, its not only doing the job of smoothening the vapor, it cools it really noticeable - for whatever reason.

here what i order for a full bulli setup, with original order numbers. for the mouth piece take either the orignal drip tip adaptder i used with spray

108 = Drip-Tip Adapter V2 =

or the tank cut until the end

111 = Edelstahl Leerdepot A2 =

and the rest of the bulli

109 = Kanülensockel = Material:Edelstahl

73 > Ersatzsockel A2 Edelstahl <

63 =Bulli-Smoker A2-TM Downgrade -> Klassik= Material:Edelstahl

to hold the mesh i made some swinged form with the awg22 316l we all have around like seen in the third pic. so no gum or silicone parts needed, all plain metal in the vapour path.

i use a fine mesh in above the heating elementl and a wider one for the bulli corpus to hold plant matter.

regarding air inflow, i find 5 holes with 1 mm works best for me. more small holes seem to distribute the heat more even, and sure are the reason for less noise compared to one or two holes for reaching the same diameter.

as software i use the myevic firmware. realy nice to have it open source.

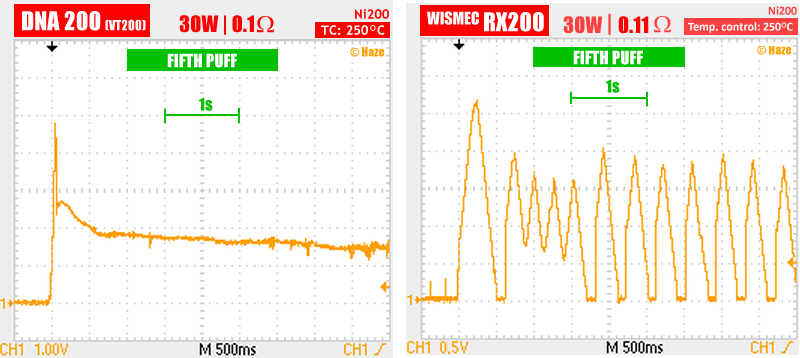

i only use 35w to take care of batteries, and in the default algorithm for not overshooting to much. with more watts the overshoot time and overheat temp is higher.. smaller watts trigger more frequent changes between in-temp and over-temp phases, resulting in less hot spots.

but really the pid algo is what i use, as i see over or under-shoots of only 2 to 3 degrees. i use 1600 as p, 80 as i and d is 0. with the 35 wats it takes 2 to 3 seks to reach temp, but no overshooting and only small changes as mentioned. if you use more watts increase the i value for less overshooting, which will result also in reaching temp faster. the default algo overshoots some times about 20 to 30 degree and even more. also when i use a 0.48 ohm coil i used that pid numbers with good results.

i see some comments and now even in the project faq about the wish to adjust a temperature referring to the bowl temp and not the coil temp. people do that by adjusting the coil ohms and tcr values manually.

i already did a patch for an older myevic firmware, and now for a recent one. all coil readings and the internals work the same, just whenever the temp is shown in the display it is shifted by the offyset which is set in the expert menu. i use it since days without problems, having increased the shift possibility just today to 99. use this firmware on your own risk and responsability, no warranty given.

http://ge.tt/6QNIwEi2

this is really the mobile log vape i was waiting for. thanks pipes for sharing your ideas.

i even dont miss it when i travel. since all is metal, just clean in an iso bath and good to go.

#bullilife (c:

regards

moqua

Very nice work!

Very nice work! but they rolled up a piece of SS mesh, and used that roll to form a coil. Did anybody experiment with this?

but they rolled up a piece of SS mesh, and used that roll to form a coil. Did anybody experiment with this?