AWistfulNihilist

Well-Known Member

Hey Everyone,

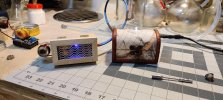

Finally decided to make an account and post, been lurking around here for a bit! A lot of inspiration for this device came from these threads. I'd like to walk you all through the current version of an induction powered vaporizer made from easily (hopefully) sourced parts. I wanted it to also function as a stand alone IH for a vapcap as well, multi-purpose is always better.

Parts list:

Sorry about the Imgur imbed, was having trouble figuring out how to imbed images directly in here. The final picture is probably .3, maybe .4g of herb with some concentrate. Heat up is around 1 minute, full extraction took around 4 minutes.

I have a video walk through including a full session using it, it's currently loading up on the ol' youtube, so for now you can check out this video for the body pre-box and the old glass set up:

Problems that need solving:

Finally decided to make an account and post, been lurking around here for a bit! A lot of inspiration for this device came from these threads. I'd like to walk you all through the current version of an induction powered vaporizer made from easily (hopefully) sourced parts. I wanted it to also function as a stand alone IH for a vapcap as well, multi-purpose is always better.

Parts list:

- Standard 5-12v zvs induction driver w/coil (amazon, ebay, alibaba, whatevs)

- 14mm female to 18mm male long glass adapter (not the single piece, the stacked piece with a donut shaped connector between)

- vapcap you are willing to cut the top and tab off of (I had a couple of broke ones)

- 3mm steel balls, I'm using 440c, but no reason you can't use 316. 10 or 15 is plenty.

- Some type of glass bead or pearl to fill to void. Borosilicate, ruby, quartz, sic, whatever works. I'm arriving at 3-4mm borosilicate beads, cheaper and no danger of getting so hot you would break or melt them.

- 12v 8amp power supply

- Button trigger. I'm using just a high capacity button wired directly to the power supply right now, I'm upgrading this to a mosfet protected momentary button with a 12v relay/delay to trigger a 30-60 second pulse. I'll wire the output to the led on the button so it's on while the induction heater is working, giving you an integrated indicator without having to wire an extra led.

- Wiring components, female barrel connector, 16-20awg wire, wire nuts or wago connectors

- 2x ss 14mm basket screens, 2x ss 18mm basket screens. 1 or 2 1/2" SS pipe screens to block the beads from the weed at the beginning of the 18mm male joint.

Sorry about the Imgur imbed, was having trouble figuring out how to imbed images directly in here. The final picture is probably .3, maybe .4g of herb with some concentrate. Heat up is around 1 minute, full extraction took around 4 minutes.

I have a video walk through including a full session using it, it's currently loading up on the ol' youtube, so for now you can check out this video for the body pre-box and the old glass set up:

Problems that need solving:

- I'm exceeding the duty cycle on this IH, but what does that mean for the unit, failure or chance of dangerous failure?

- Current button set-up needs work, no mosfet, have to hold the momentary down for a while

- possible fix: latching momentary or relay/delay to create timed cutoff (what I'm doing)

- Having to cut a vapcap sucks, but it's so fucking perfect. I have some 316 solderless ss tubing coming in a couple sizes, hoping to find something cheap and easy to get/cut.

- Corrosion? All the SS is getting heating to somewhere around 600f. No coating left after that.

- Anything else you can think of!