Available later this week (Assuming it passes my tests)

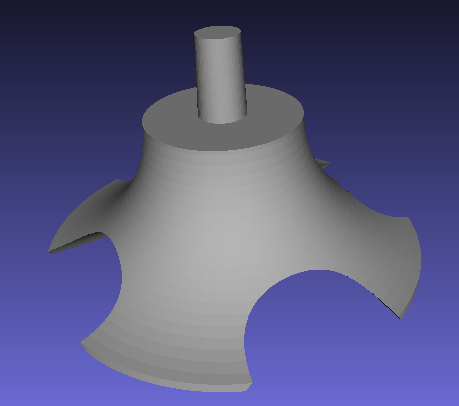

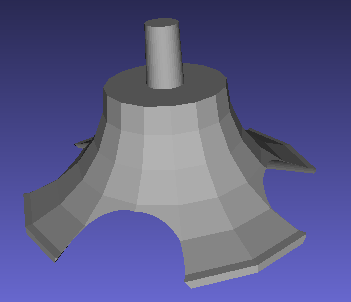

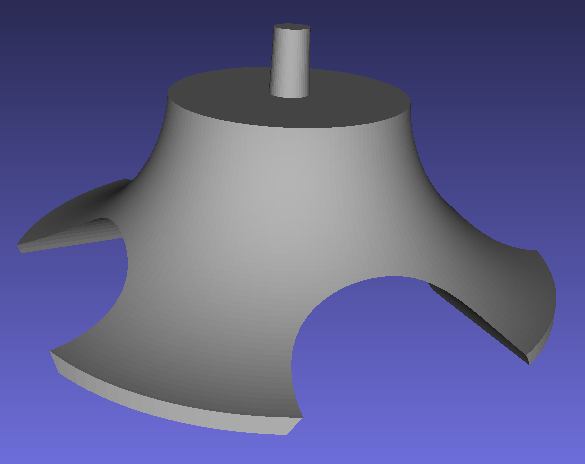

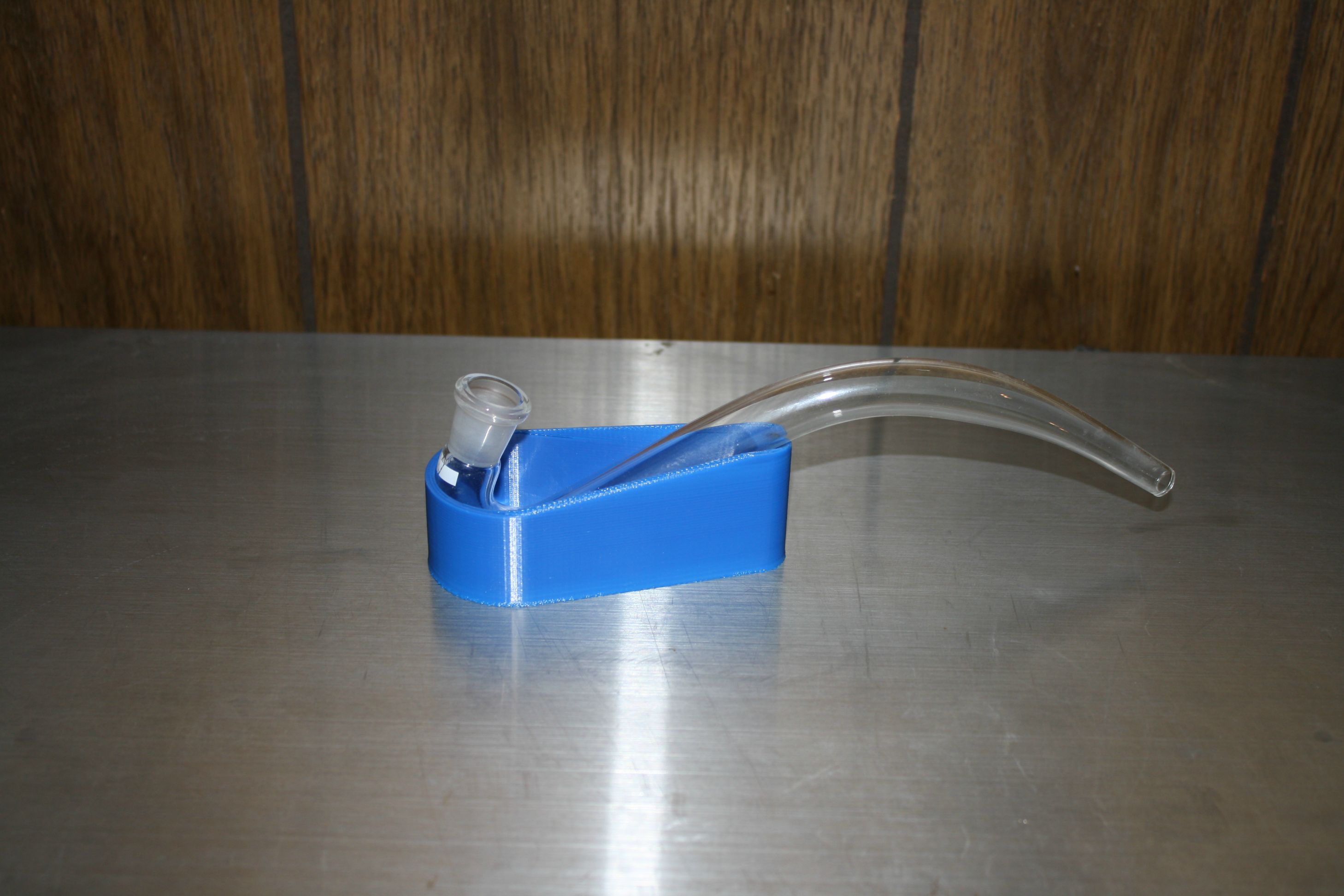

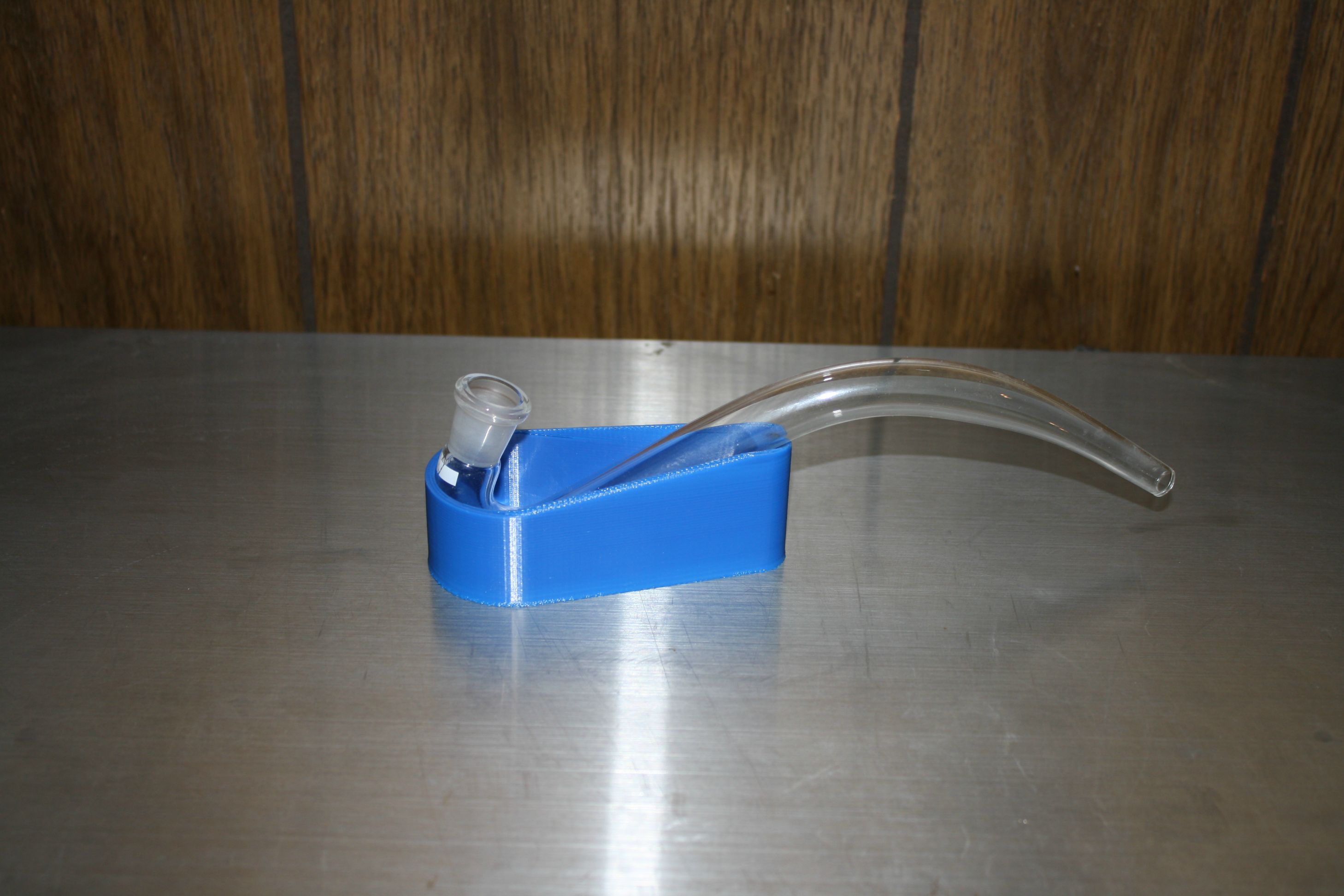

Teardrop J-Hook Stand (Parameter based, can adjust every aspect of this design as needed - I've actually already made several changes since this design)

Coming Soon:

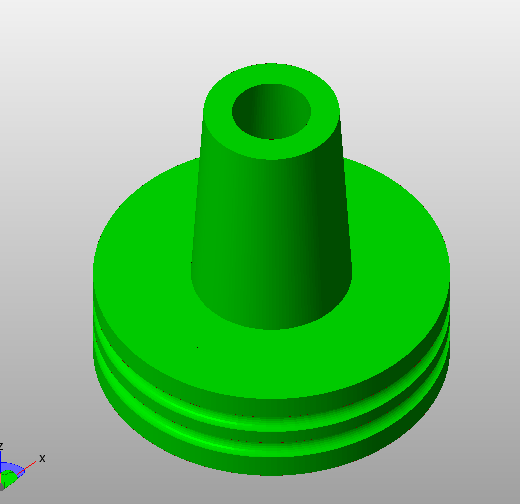

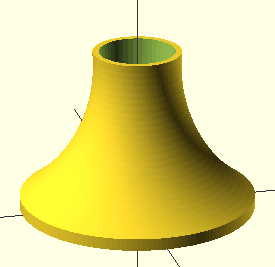

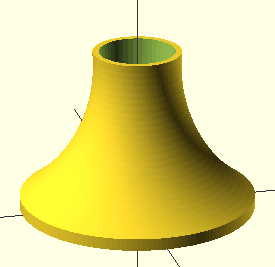

14mm and 18mm Male GONG stands

--------------

On another note, I have decided that your support has inspired me to purchase my next 3D printer (4th one) - this one should hopefully keep up with my creative spirit and prove to be more reliable than my other home-built machines. If all goes well, I should have that printer up and running 24/7 before August!

Teardrop J-Hook Stand (Parameter based, can adjust every aspect of this design as needed - I've actually already made several changes since this design)

Coming Soon:

14mm and 18mm Male GONG stands

--------------

On another note, I have decided that your support has inspired me to purchase my next 3D printer (4th one) - this one should hopefully keep up with my creative spirit and prove to be more reliable than my other home-built machines. If all goes well, I should have that printer up and running 24/7 before August!

Last edited by a moderator: