Hackerman

User

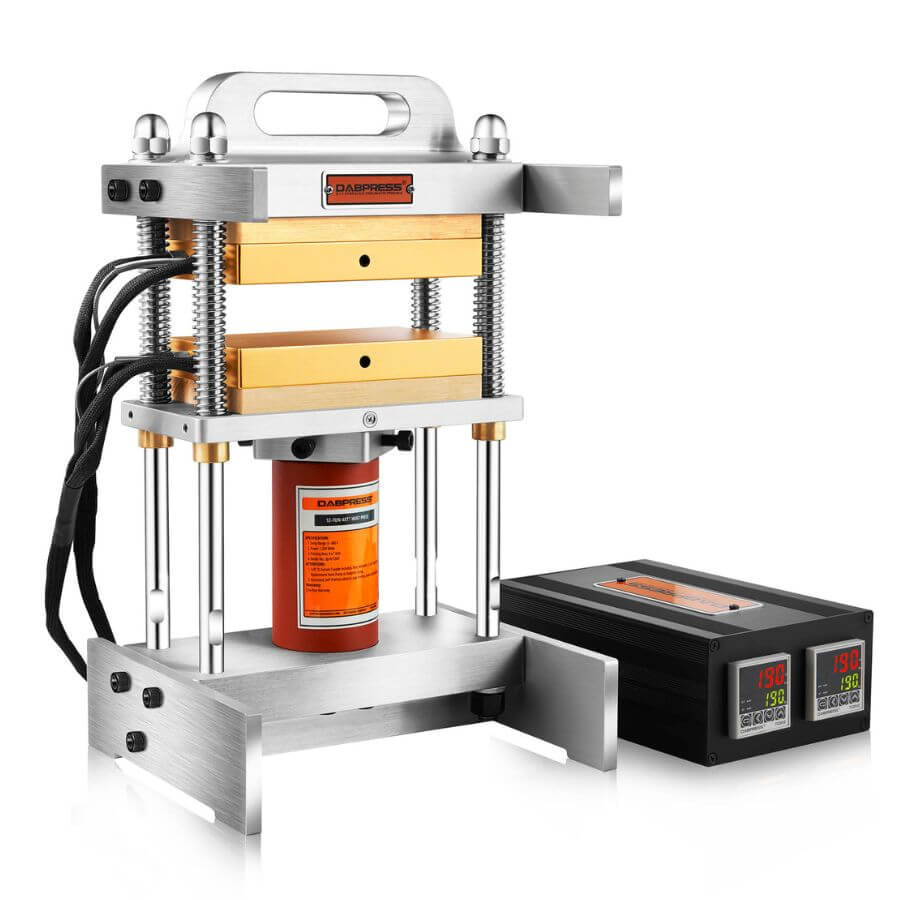

@somerandomguy1 Are you sure it has oil? If a bottle jack is shipped on it's side, sometimes it will leak out the oil.

If you are sure it has oil, very often bottle jacks have 1 or 2 screws at the base near the pump action that adjust the flow in and out. They need to be balanced or the jack won't stay tight.

Pump it up all the way and start adjusting one of the screws as you pump. One of the screws will adjust the flow so it's balanced.

If you are sure it has oil, very often bottle jacks have 1 or 2 screws at the base near the pump action that adjust the flow in and out. They need to be balanced or the jack won't stay tight.

Pump it up all the way and start adjusting one of the screws as you pump. One of the screws will adjust the flow so it's balanced.