Well,although @Pipes has made an awesome thread about IH ,

I thought ,oh well ,multiple brains are better than a single one

when it comes to the evolution of an idea .

So here we are !

At this thread all sorts of trivia about IH can be posted .

Helpful information ,tips'n' tricks ,mods ,alternative designs ,microcontroller hardware and software ,etc.

So ,let's start .

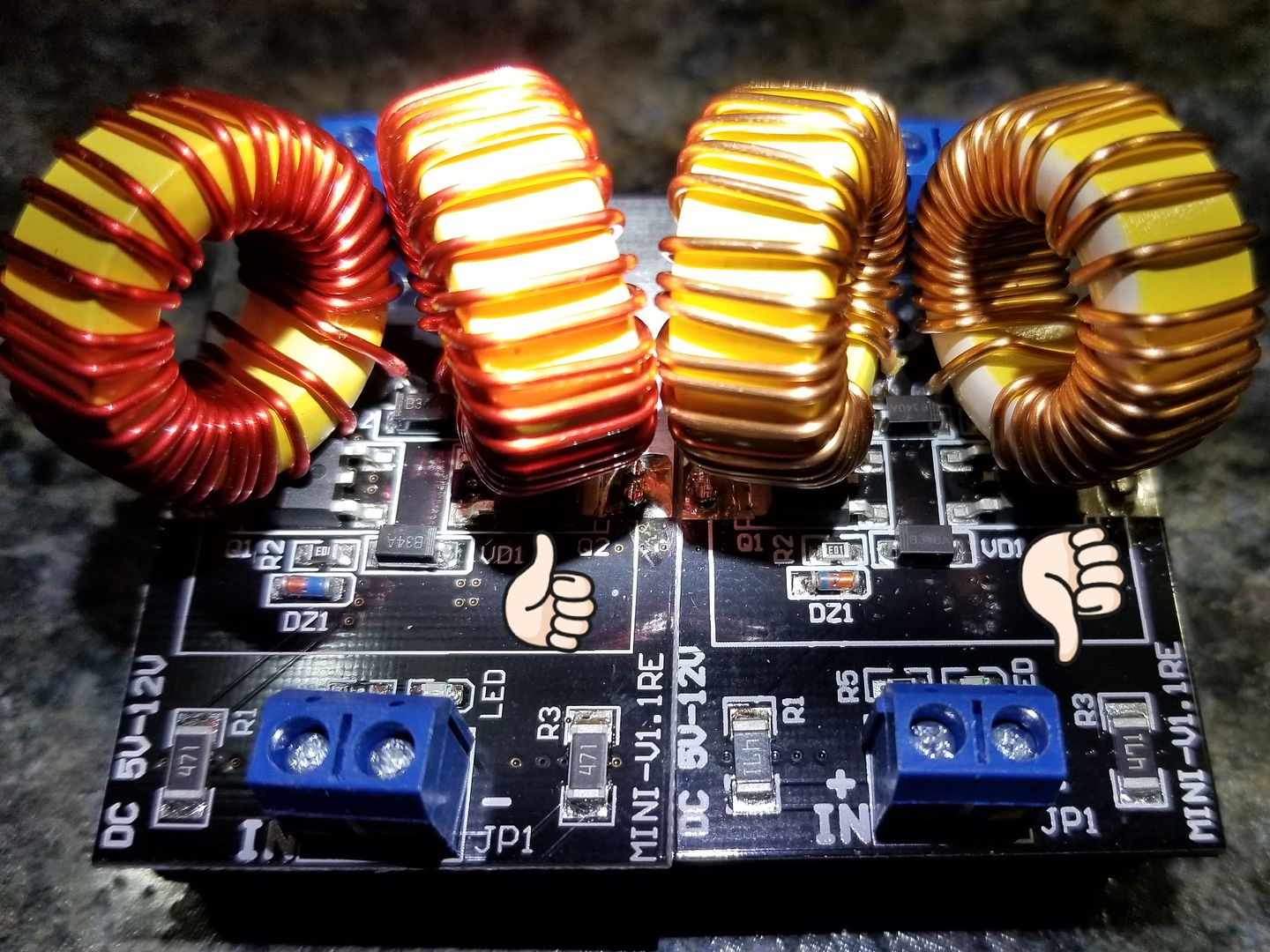

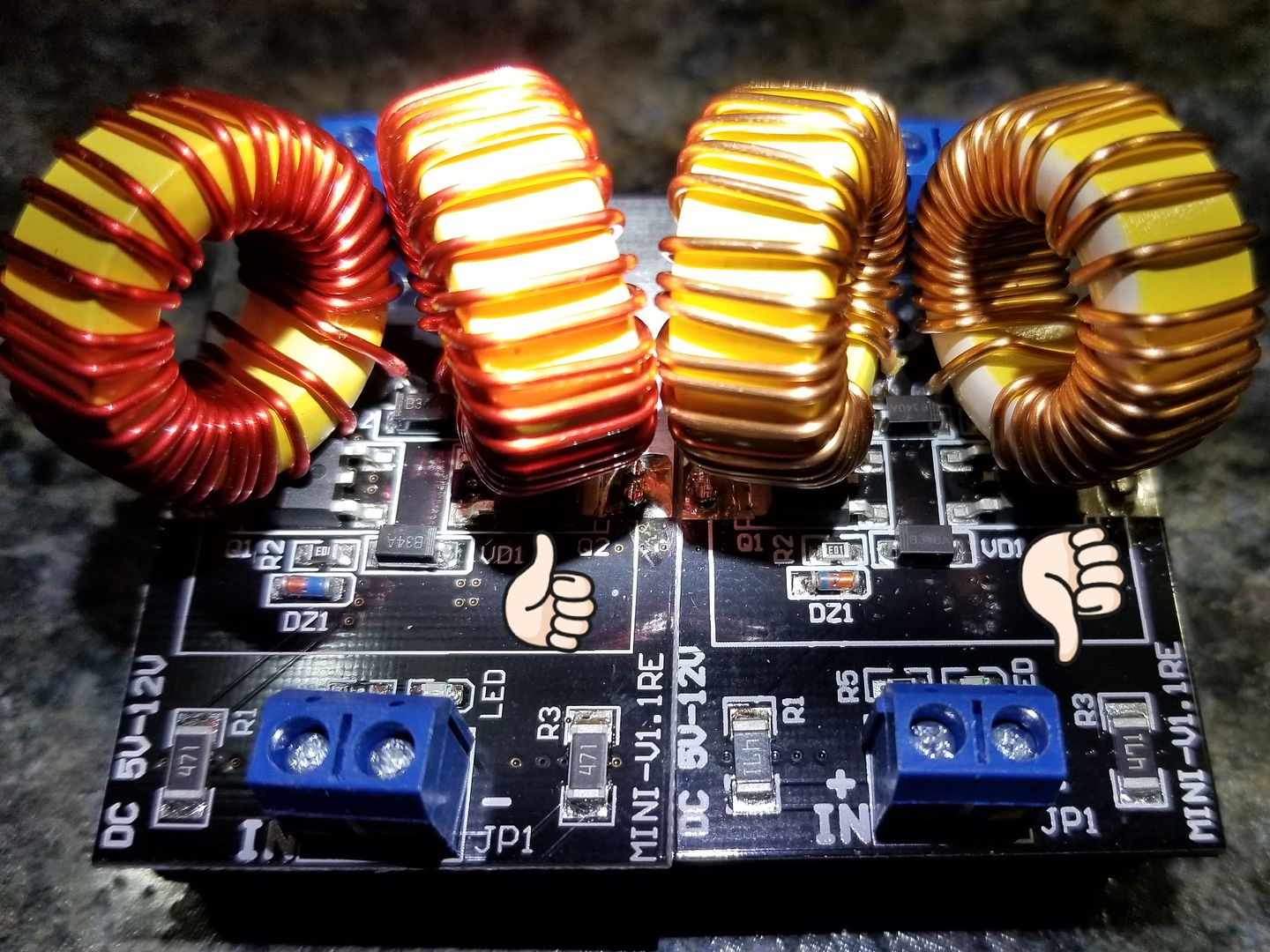

The 5~12v ZVS Induction Heating Power Supply Module ,

is the cheapest ,simplest and easiest to obtain IH driver .

It can be found on E-bay ,Bang-Good ,Fastech ,Aliexpress,Amazon ,Sainsmart,Walmart

and at quite few other web -markets .

First thing for the brave DIYer is to check the polarity of the diodes VD1 & VD2 ,as

also the polarity of the two Zener diodes DZ1 & DZ2 .

Some of these drivers have not been under QC ,thus you should check the polarity

of these four diodes ,before assembling & powering the IH device .

DZ1 & DZ2 have a blue line indicating the cathode

( aka "minus side/pole " aka " to ground " or " to GND " aka " to 0V " ) .

Same with VD1 & VD2 ,which have a grey/white line .

At DZ1 & DV1 the cathode side should be facing towards the "JP1 " power connection post .

At DZ2 & VD2 the cathode is inverted ,facing the " +IN " power connection post .

--------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

These drivers can fry their two MOSFETS quite easily ,

due to low battery voltage ,bad coil installation ,rapid ON/OFF cycles ,etc .

The original MOSFET is the 30N06 ( 32 A ,60 V ) N-channel power MOSFET.

Datasheet :

https://cdn.sparkfun.com/datasheets/Components/General/FQP30N06L.pdf

http://www.unisonic.com.tw/datasheet/30N06.pdf

https://gr.mouser.com/datasheet/2/196/Infineon-IPD30N06S2L_13-DS-v01_00-en-1226066.pdf

Source :

https://gr.mouser.com/ProductDetail/Infineon-Technologies/IPD30N06S2L13ATMA4?qs=sGAEpiMZZMshyDBzk1/Wi%2bcEGIVrBqg7d7tRVdUCWI3CHJrx/iMcrg==

But other N-channel power FETs can be used instead of the 30N06 .

Some replacement examples :

IRF540N ( 33 A ,100 V ) A really "tough" FET ! :

https://www.infineon.com/dgdl/irf540n.pdf?fileId=5546d462533600a4015355e396cb199f

IRFP260N ( 50A ,200V ) Most probably the best alternative.A real work-horse ! :

https://www.infineon.com/dgdl/irfp260n.pdf?fileId=5546d462533600a4015356289dcf1fe2

https://www.vishay.com/docs/91215/91215.pdf

IRFZ44 ( 50A ,60 V ) Very close specs to the 30N06,

but somewhat a better FET than the latter :

https://www.vishay.com/docs/91291/91291.pdf

@Pipes uses the NTD4806N ( 76 A , 30 V ) with great results ! :

https://www.onsemi.com/pub/Collateral/NTD4806N-D.PDF

I thought ,oh well ,multiple brains are better than a single one

when it comes to the evolution of an idea .

So here we are !

At this thread all sorts of trivia about IH can be posted .

Helpful information ,tips'n' tricks ,mods ,alternative designs ,microcontroller hardware and software ,etc.

So ,let's start .

The 5~12v ZVS Induction Heating Power Supply Module ,

is the cheapest ,simplest and easiest to obtain IH driver .

It can be found on E-bay ,Bang-Good ,Fastech ,Aliexpress,Amazon ,Sainsmart,Walmart

and at quite few other web -markets .

First thing for the brave DIYer is to check the polarity of the diodes VD1 & VD2 ,as

also the polarity of the two Zener diodes DZ1 & DZ2 .

Some of these drivers have not been under QC ,thus you should check the polarity

of these four diodes ,before assembling & powering the IH device .

DZ1 & DZ2 have a blue line indicating the cathode

( aka "minus side/pole " aka " to ground " or " to GND " aka " to 0V " ) .

Same with VD1 & VD2 ,which have a grey/white line .

At DZ1 & DV1 the cathode side should be facing towards the "JP1 " power connection post .

At DZ2 & VD2 the cathode is inverted ,facing the " +IN " power connection post .

--------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

These drivers can fry their two MOSFETS quite easily ,

due to low battery voltage ,bad coil installation ,rapid ON/OFF cycles ,etc .

The original MOSFET is the 30N06 ( 32 A ,60 V ) N-channel power MOSFET.

Datasheet :

https://cdn.sparkfun.com/datasheets/Components/General/FQP30N06L.pdf

http://www.unisonic.com.tw/datasheet/30N06.pdf

https://gr.mouser.com/datasheet/2/196/Infineon-IPD30N06S2L_13-DS-v01_00-en-1226066.pdf

Source :

https://gr.mouser.com/ProductDetail/Infineon-Technologies/IPD30N06S2L13ATMA4?qs=sGAEpiMZZMshyDBzk1/Wi%2bcEGIVrBqg7d7tRVdUCWI3CHJrx/iMcrg==

But other N-channel power FETs can be used instead of the 30N06 .

Some replacement examples :

IRF540N ( 33 A ,100 V ) A really "tough" FET ! :

https://www.infineon.com/dgdl/irf540n.pdf?fileId=5546d462533600a4015355e396cb199f

IRFP260N ( 50A ,200V ) Most probably the best alternative.A real work-horse ! :

https://www.infineon.com/dgdl/irfp260n.pdf?fileId=5546d462533600a4015356289dcf1fe2

https://www.vishay.com/docs/91215/91215.pdf

IRFZ44 ( 50A ,60 V ) Very close specs to the 30N06,

but somewhat a better FET than the latter :

https://www.vishay.com/docs/91291/91291.pdf

@Pipes uses the NTD4806N ( 76 A , 30 V ) with great results ! :

https://www.onsemi.com/pub/Collateral/NTD4806N-D.PDF

Last edited:

So much great info

So much great info