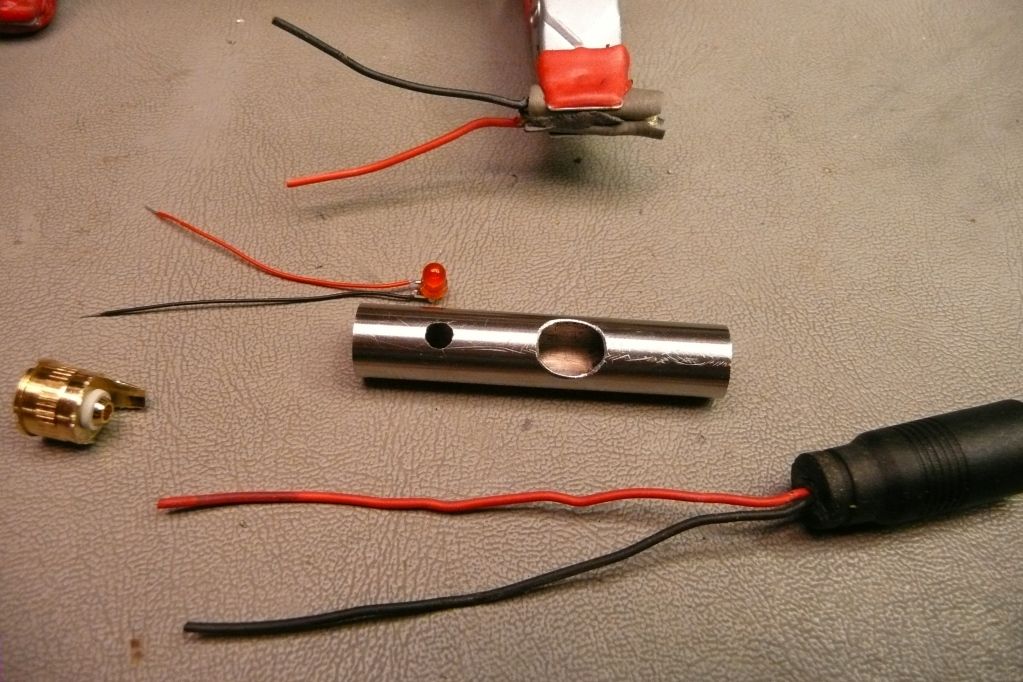

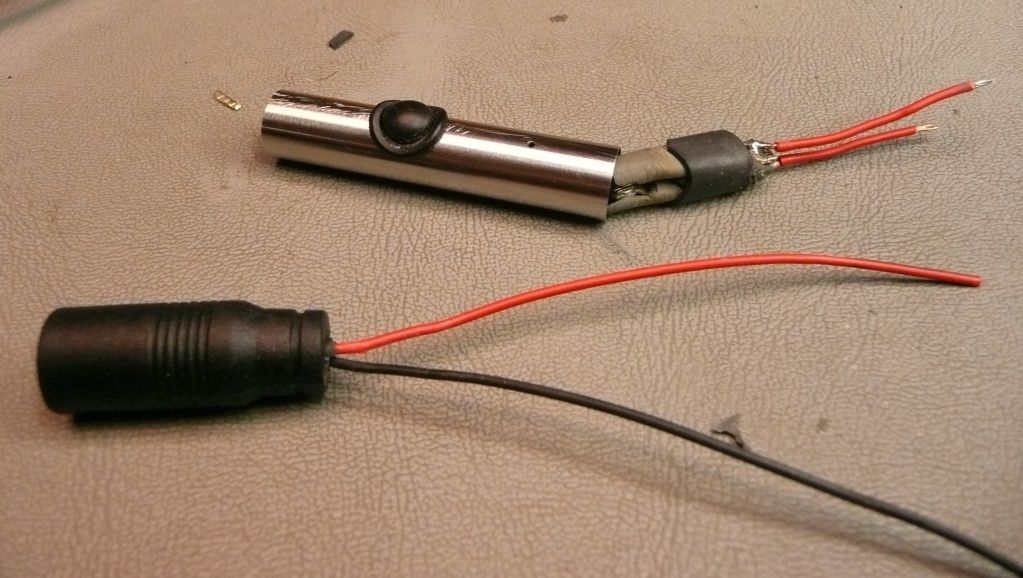

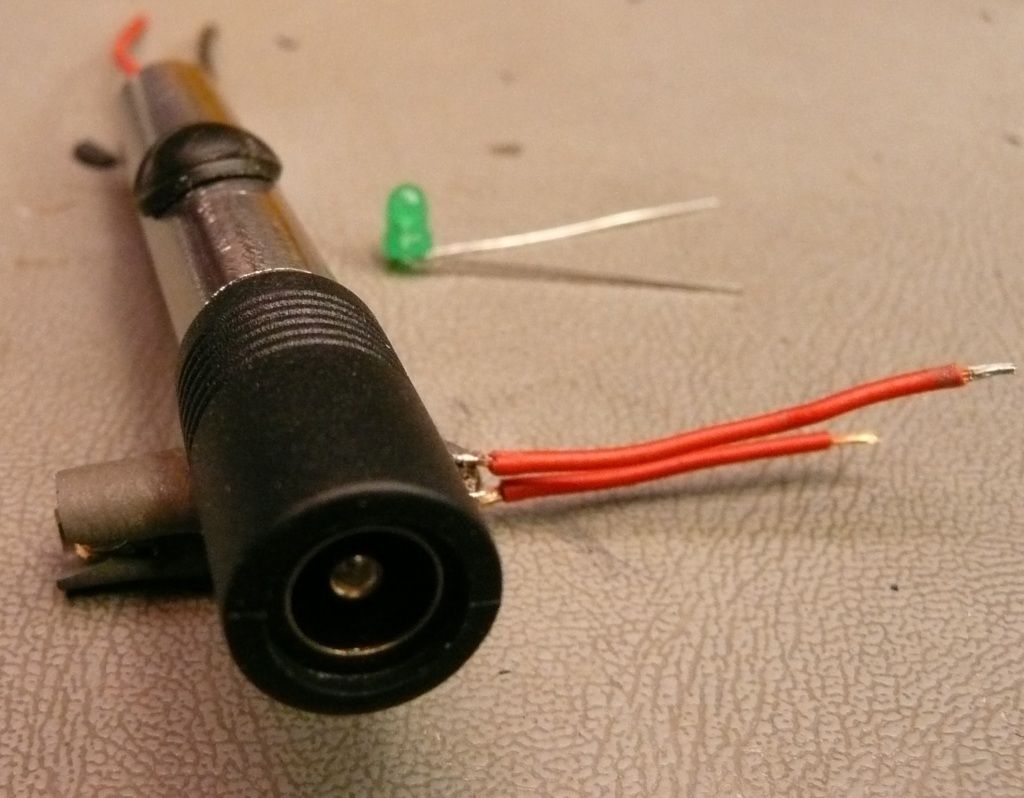

I have been thinking about a spare power handle for my 510 devices. I currently have a TV and a KnightRider handles which the TV takes priority for various reasons. Since I use an external power supply as much as possible I thought this mod would do the job. And cheap, cheap, cheap. At first I just through together a unit with no switch but was a quick and dirty way to get power to the device. It is basically a long 510 extender peice with a DC plug mounted on one end.

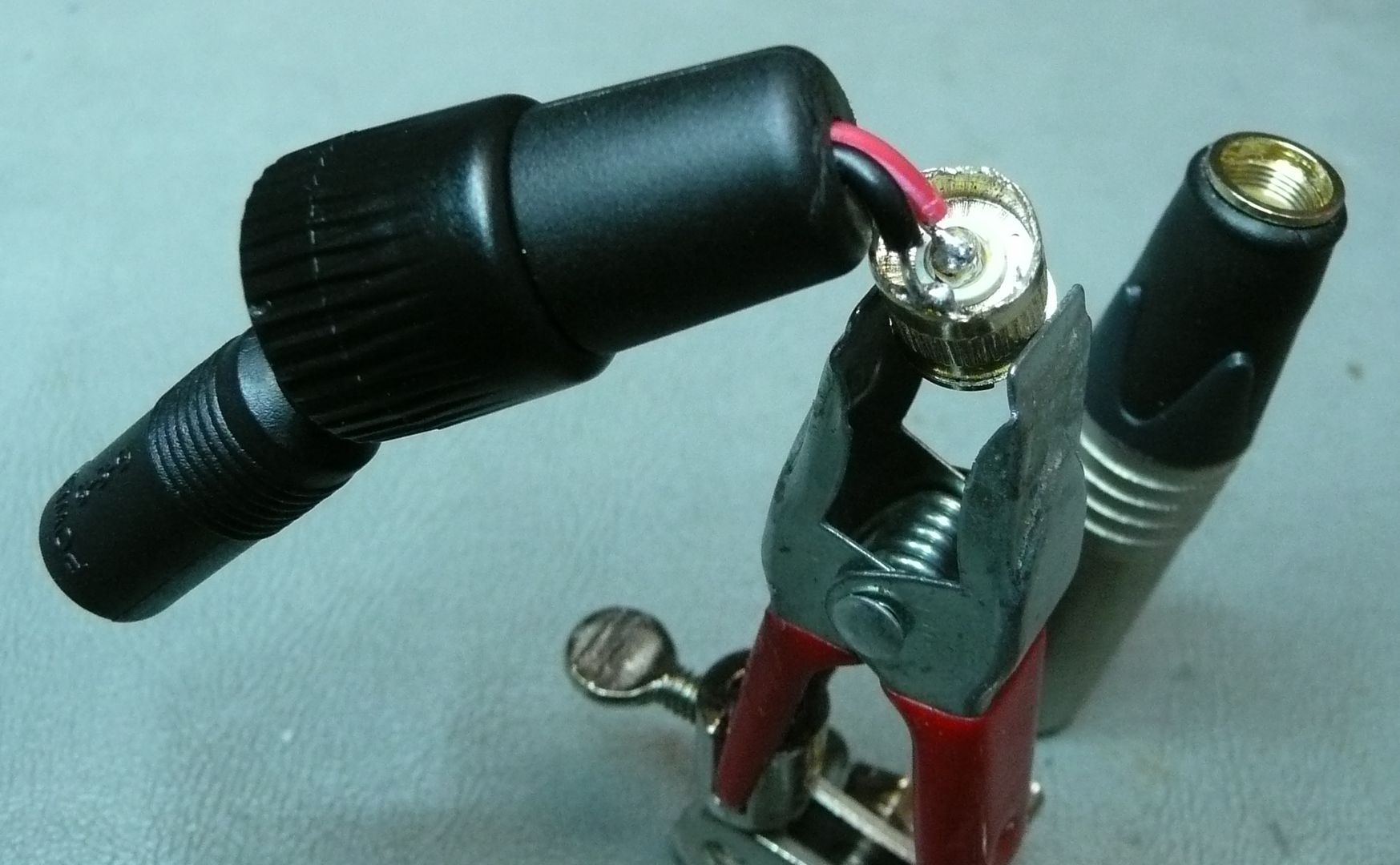

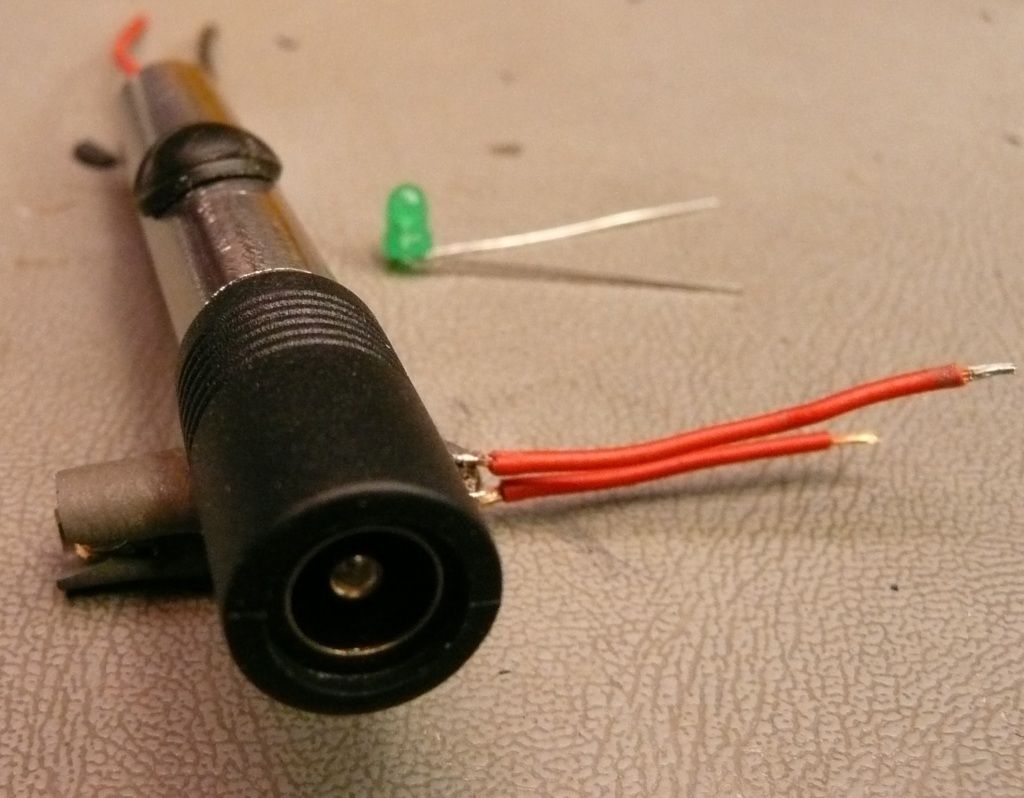

Tried it and worked like a charm. Put some thought into it and started putting some parts together. Found a button plug from an old industrial camera lens (Canon). This would make for a cosmically good button.

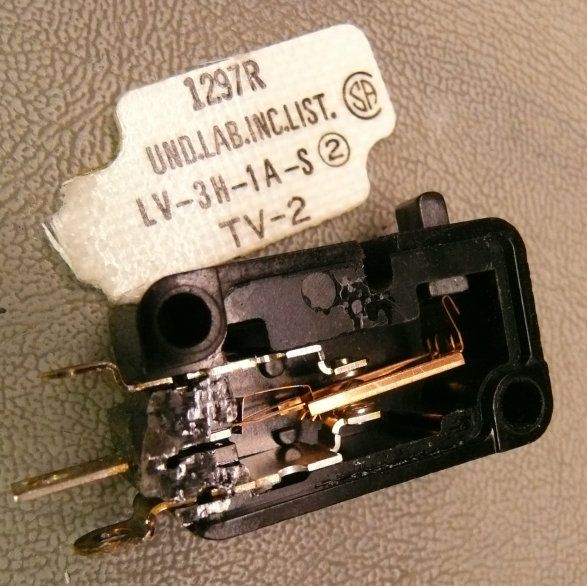

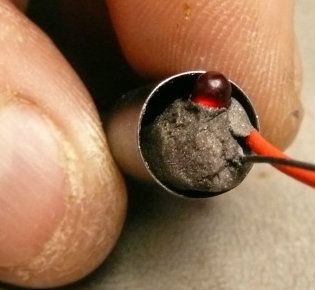

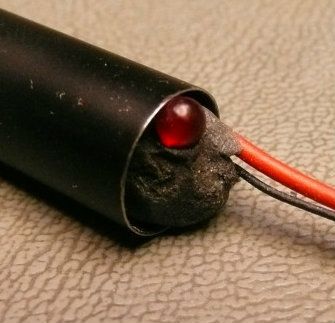

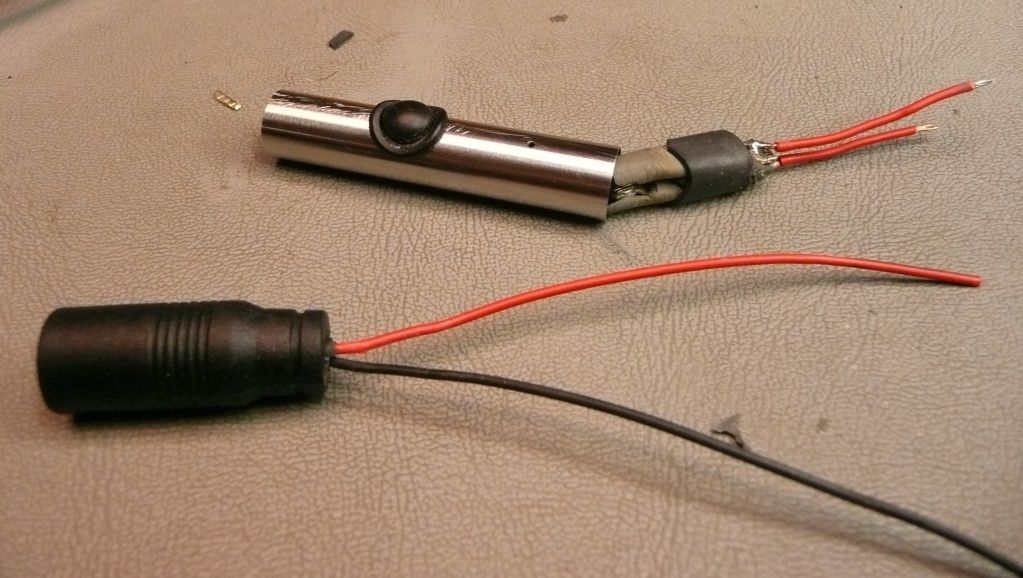

Then I took apart an end sensor type switch. A relay would have worked as well. Removed the contacts and arranged in such a way that pushing down on it will make contact. I used JB weld and shrink wrap to have it stay in the configured position.

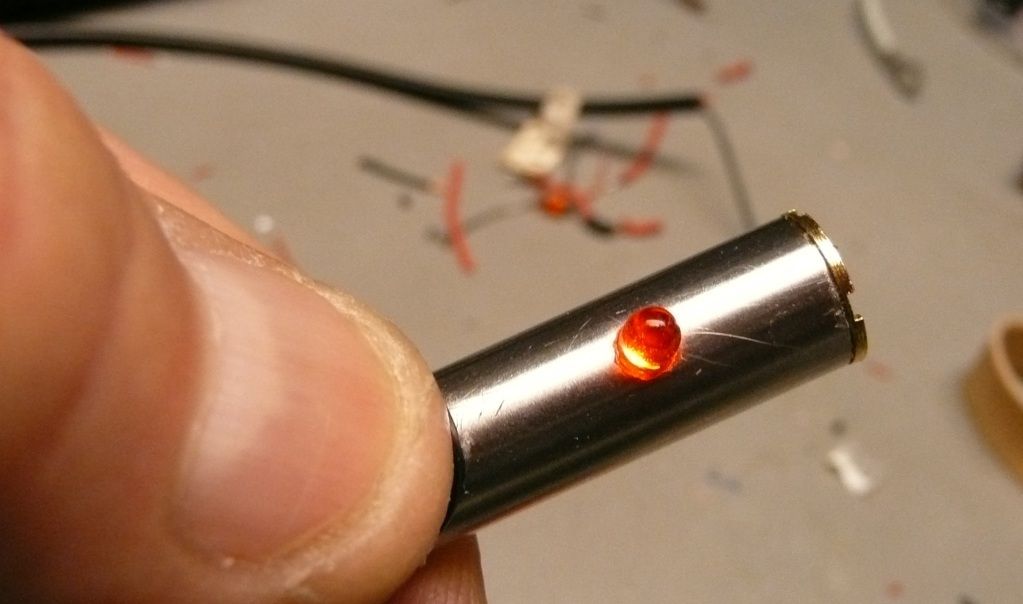

I also thought I'd throw in an LED as well for an indicator.

I have not completed this mod yet but have no doubt it will work. This is where I have left it off and will continue tonight with it.

Seems like a cool back-up unit and very discreet. Extenders can be added if heat is a problem. Or just for the heck of it.

I will follow up after complete.

Cheers,

Pipes

Tried it and worked like a charm. Put some thought into it and started putting some parts together. Found a button plug from an old industrial camera lens (Canon). This would make for a cosmically good button.

Then I took apart an end sensor type switch. A relay would have worked as well. Removed the contacts and arranged in such a way that pushing down on it will make contact. I used JB weld and shrink wrap to have it stay in the configured position.

I also thought I'd throw in an LED as well for an indicator.

I have not completed this mod yet but have no doubt it will work. This is where I have left it off and will continue tonight with it.

Seems like a cool back-up unit and very discreet. Extenders can be added if heat is a problem. Or just for the heck of it.

I will follow up after complete.

Cheers,

Pipes