smokeliss

New Member

Hi everyone,

New here, but thought you would all like to have a look at what I’m starting to put together.

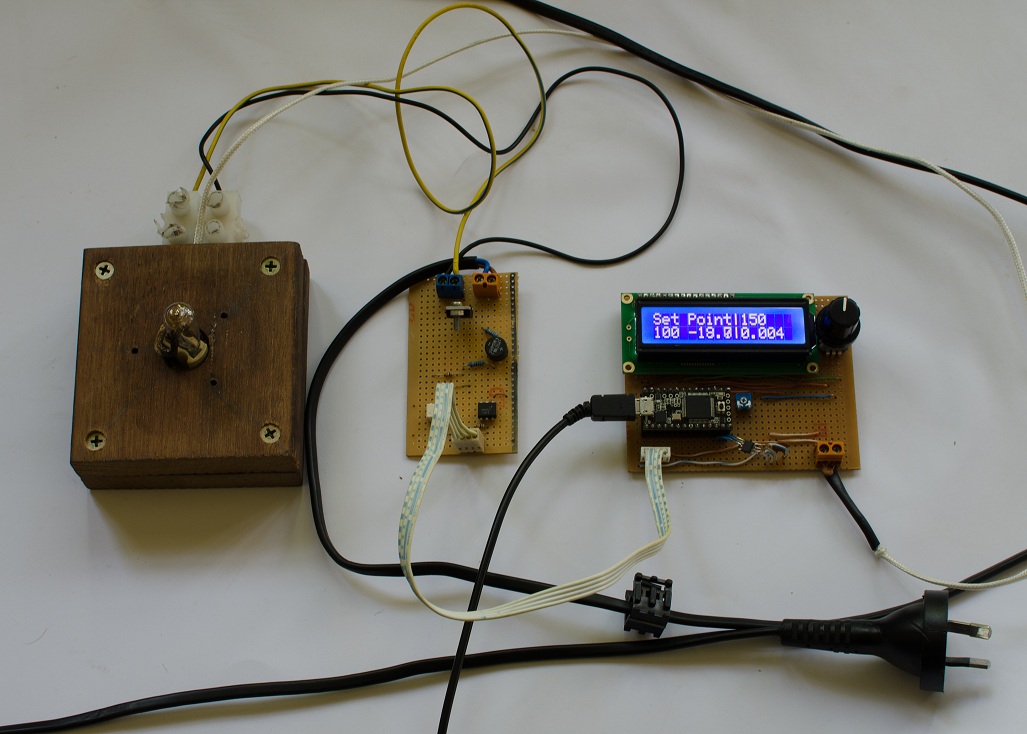

This is the current test bed.

Left to right:

Test stand, currently using a single 100W 240v halogen bulb. Planning on upping it to 3x 150W halogen tubes. Thermocoulpe is sitting next to the bulb here.

Middle: Heater driver, TRIAC controlled, took heat sink off temporary, may be needed if upping it to 450W

Right: Controller board, running a teensy 3.0, rotary encoder for input and a 12x2 LCD. The temperature is read by a K thermocouple and picked up by a max31855. This chip is designed for K types and is digitally read by the microcontroller.

My goal for this is to be a quality unit. Durable, fast heat up, large capacity, be able to leave it on safely and not look like drug paraphernalia.

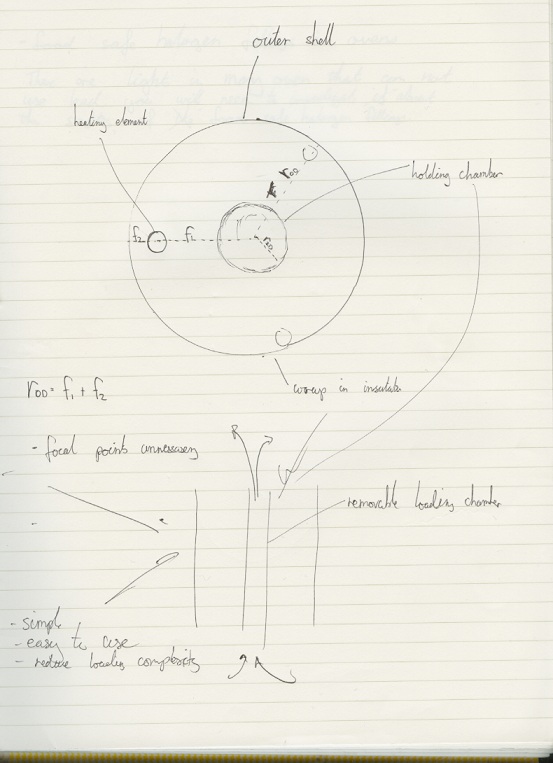

Now that the basic controller is sorted, the next step will be to prototype the holding chamber and house the high voltage circuit (and fuse it). Currently working on a better interface, it will not have a LCD or LED segment read out, but analog display while still retaining high precision (+/- 2.5deg of the 31855).

Jason

New here, but thought you would all like to have a look at what I’m starting to put together.

This is the current test bed.

Left to right:

Test stand, currently using a single 100W 240v halogen bulb. Planning on upping it to 3x 150W halogen tubes. Thermocoulpe is sitting next to the bulb here.

Middle: Heater driver, TRIAC controlled, took heat sink off temporary, may be needed if upping it to 450W

Right: Controller board, running a teensy 3.0, rotary encoder for input and a 12x2 LCD. The temperature is read by a K thermocouple and picked up by a max31855. This chip is designed for K types and is digitally read by the microcontroller.

My goal for this is to be a quality unit. Durable, fast heat up, large capacity, be able to leave it on safely and not look like drug paraphernalia.

Now that the basic controller is sorted, the next step will be to prototype the holding chamber and house the high voltage circuit (and fuse it). Currently working on a better interface, it will not have a LCD or LED segment read out, but analog display while still retaining high precision (+/- 2.5deg of the 31855).

Jason