You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Dabpress Rosin Plates

- Thread starter dabpress.com

- Start date

Jblizz

Well-Known Member

Thanks brother. Appreciate you taking care of me. Very happy with 26% yield (Watermelon Zkittlz).

There are a few places in Oz that reach that temperature fairly regularly (airconditioning is great)not supposed to be operated when they are over 105F.

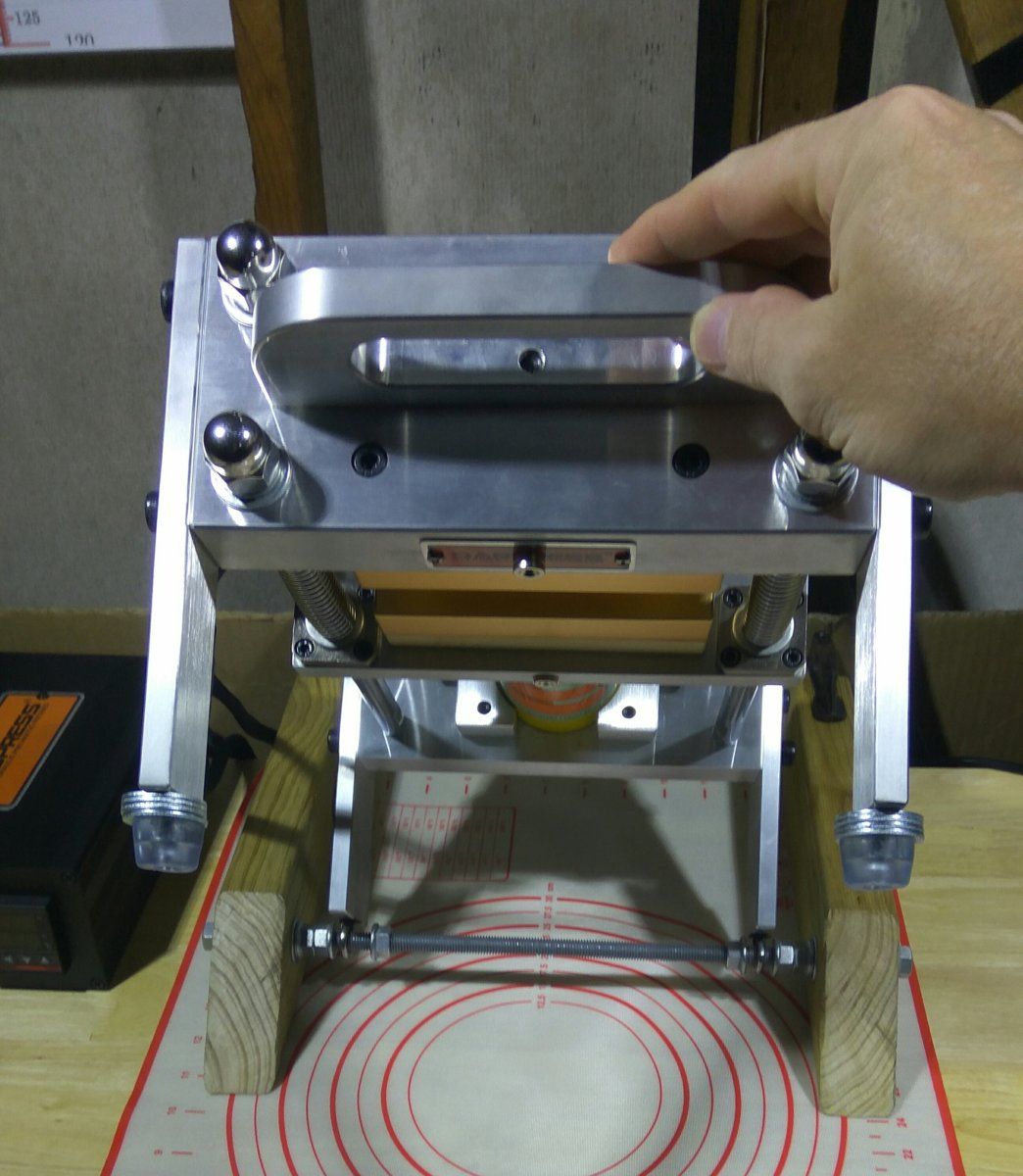

Added an axel(10mm threaded rod) to the bottom of my HR10t35v by removing the rubber feet and replacing with M4 eyebolts(10mm ID, direct swap, no mods needed). A few nuts to suit and now I can tilt for driptech with a couple of fingers;

superdang9000

Flameo Hotman!

There are a few places in Oz that reach that temperature fairly regularly (airconditioning is great)

Added an axel(10mm threaded rod) to the bottom of my HR10t35v by removing the rubber feet and replacing with M4 eyebolts(10mm ID, direct swap, no mods needed). A few nuts to suit and now I can tilt for driptech with a couple of fingers;

Man, I love the ingenuity here!

I'm going to try rigging up something similar!

I'm going to try rigging up something similar!Don't you like treated pine and hot-dip galvanized hardware?the same and matched nicely

This is still prototyping for me, I have stainless steel hardware coming and have a cousin(I am Tasmanian, we are all related)who is a first-class machinist that might make me a couple of legs that the now 4 spare rubber feet will attach to (once I finalize the height I want the axel at).

pxl_jockey

Just a dude

This is really cool @LesPlenty love seeing practical innovations! This prototype of yours is fucking brilliant and besides everybody uses cheap materials during these phases, you save the quality for the final GA product. I’ve always been convinced that you’re waaay smarter than you let on, with that self-deprecating Tasmanian demeanour, this invention just proves it beyond a doubt. Turns out Les is plenty intelligent! Deny it if you can!

As far as Tasmanians all being related that must be really cool to have all those connections. But if they were anything like my family, that’s a whole lotta nosiness and judgement. Hell I had to leave the US entirely and move my family halfway around the world just to get some peace! I’d love to have cool relatives...

As far as Tasmanians all being related that must be really cool to have all those connections. But if they were anything like my family, that’s a whole lotta nosiness and judgement. Hell I had to leave the US entirely and move my family halfway around the world just to get some peace! I’d love to have cool relatives...

Hackerman

User

Hey @psychonaut , did I remember you saying that the PIDs for the e-nail and the sauce plate are (or are going to be) interchangeable?

Would be nice to get a package with 1 PID and 1 sauce plate, 1 nail and whatever other options and accessories may be available later.

Thought I remembered you mentioning that.

Would be nice to get a package with 1 PID and 1 sauce plate, 1 nail and whatever other options and accessories may be available later.

Thought I remembered you mentioning that.

Hey @psychonaut , did I remember you saying that the PIDs for the e-nail and the sauce plate are (or are going to be) interchangeable?

Would be nice to get a package with 1 PID and 1 sauce plate, 1 nail and whatever other options and accessories may be available later.

Thought I remembered you mentioning that.

The PID is the same model but it powers a different wattage heater with different settings on the PID menu. You wouldn't be able to move a PID module from the e-nail and into the sauce plate PID, or vice versa, without making the necessary changes.

The heating rods on the sauce plate run at 300W each like our dp-rp37 3x7" caged plates. The heater coil for our e-nail unit runs at 150W and the PID can run as hot as 1000F.

There are a few places in Oz that reach that temperature fairly regularly (airconditioning is great)

Added an axel(10mm threaded rod) to the bottom of my HR10t35v by removing the rubber feet and replacing with M4 eyebolts(10mm ID, direct swap, no mods needed). A few nuts to suit and now I can tilt for driptech with a couple of fingers;

I think you should throw a set of wheels on that fucker and call it carry on luggage

Hackerman

User

The PID is the same model but it powers a different wattage heater with different settings on the PID menu. You wouldn't be able to move a PID module from the e-nail and into the sauce plate PID, or vice versa, without making the necessary changes.

The heating rods on the sauce plate run at 300W each like our dp-rp37 3x7" caged plates. The heater coil for our e-nail unit runs at 150W and the PID can run as hot as 1000F.

Thanks bud. Guess I remembered incorrectly. LOL

Really loving that sauce plate. It seems perfect for decarbing rosin and cooking terps for edibles. I use a hotplate now but real temperature control would be great. Going to grab one of those soon. Just thought it would be cool to swap the plate and the nail. Too bad. Thanks again.

CR250M

Ontario, CA

@psychonaut, using 90u bags hand filled 5g per bottle tech style, depending on product anywhere from 16% - 25% return

dron19

Well-Known Member

How does anyone check the temp on each plate compared to what the pid shows? I was thinking it may be good to double check just to be sure I’m within a few degrees... without spending $$$ on a flir gun.. lol.

There isn’t an auto tune on this pid is there?

There isn’t an auto tune on this pid is there?

Last edited:

Jblizz

Well-Known Member

How does anyone check the temp on each plate compared to what the pid shows? I was thinking it may be good to double check just to be sure I’m within a few degrees... without spending $$$ on a flir gun.. lol.

There isn’t an auto tune on this pid is there?

I bought a thermometer gun on amazon. Was an inexpensive investment (approximately $15).

FlyingLow

Team NO SLEEP!

My IR gun showed the control unit measurement was within 1-2* based on where on the plate I hit the laser... I trust the control unit is reading spot on, as its measured from the center of each plate.

My actual temp reading tends to be spot on, but the set temp and the actual temp can vary.

My actual temp reading tends to be spot on, but the set temp and the actual temp can vary.

@dron19 there is a recalibrate function but we don't recommend to use it unless your plates are well outside of the temp reading. We use independent thermocouples with our PID which is more accurate than heating rods with integrated TC.

I personally like using a k-type thermocouple for external readings and the IR thermometer as backup as mine is not as accurate I've found. I have a javelin meat probe thermometer which is very accurate, just have to be careful not to scratch the plates.

I personally like using a k-type thermocouple for external readings and the IR thermometer as backup as mine is not as accurate I've found. I have a javelin meat probe thermometer which is very accurate, just have to be careful not to scratch the plates.

dron19

Well-Known Member

@psychonaut ok thank you!..

DogBoy

know fear

...I turned on my ID condolers for the first time and noted a difference in the reading for the top and bottom plates...

...the top one read 76 F and the lower 72 F...is this normal...???...

...I am heating them now...how long should that take....???....

...should the plates be together...???....

...the top one read 76 F and the lower 72 F...is this normal...???...

...I am heating them now...how long should that take....???....

...should the plates be together...???....

I usually turn mine on first, then start weighing out and setting up, so 7 to 10 minutes at the most for me....I am heating them now...how long should that take....???....

...should the plates be together...???....

I always leave my plates open except for actually pressing, some other presses do not have heating rods in both plates so they need to be together to get both plates warm.

DogBoy

know fear

...I did my first and last press and it was a disaster...

...I feel I pretty much just wasted 5 grams of weed, never mind hundreds of $$$...

...I ran at 190F for two minutes and got no real flow and ruptured paper, with most of the stuff stuck to the upper plate...

...the bag didn't blow...

...I am packing this up and if I cannot return it, will try to sell it...

...if I don't grt to return it I have to get the pump sorted out before I can sell it, but I am not willing to feed it any more primo expensive bud...

...I did everything just like all the videos and got hosed...

...I feel I pretty much just wasted 5 grams of weed, never mind hundreds of $$$...

...I ran at 190F for two minutes and got no real flow and ruptured paper, with most of the stuff stuck to the upper plate...

...the bag didn't blow...

...I am packing this up and if I cannot return it, will try to sell it...

...if I don't grt to return it I have to get the pump sorted out before I can sell it, but I am not willing to feed it any more primo expensive bud...

...I did everything just like all the videos and got hosed...

...I did my first and last press and it was a disaster...

...I feel I pretty much just wasted 5 grams of weed, never mind hundreds of $$$...

...I ran at 190F for two minutes and got no real flow and ruptured paper, with most of the stuff stuck to the upper plate...

...the bag didn't blow...

...I am packing this up and if I cannot return it, will try to sell it...

...if I don't grt to return it I have to get the pump sorted out before I can sell it, but I am not willing to feed it any more primo expensive bud...

...I did everything just like all the videos and got hosed...

I'm sorry for your frustrations and I don't mean this the wrong way but man, if you're done after one press this was never for you. Nobody in here will tell you that they mastered rosin in one go. I've pressed a few pounds and still learning all the time. I could kinda tell from your posts that you should have done more research and reading of this thread before diving into this.

The truth is you used too much pressure and your flower was probably not as good as you thought it was. Also your temp was pretty low to encourage flow...

Sorry.

DogBoy

know fear

...I believe you may be correct on all counts...

...I was going by what I have learned here and the thing came set @ 190 which was supposed to be a good starting point...I was careful and slow with the pressure and never exceeded 2000 lbs...

...I did it just like I saw a bunch of guys on you tube do it...

...I could have lived with a less than optimal yield but most of it is stuck to the top plate and cooked to shit...

...I can't even get at it to clean...it's like I have to take the thing apart...

...I can't afford this kind of leaning curve...5 grams was a lot of weed to me...

...it was tested @ 28% THC FWIW....

...I was going by what I have learned here and the thing came set @ 190 which was supposed to be a good starting point...I was careful and slow with the pressure and never exceeded 2000 lbs...

...I did it just like I saw a bunch of guys on you tube do it...

...I could have lived with a less than optimal yield but most of it is stuck to the top plate and cooked to shit...

...I can't even get at it to clean...it's like I have to take the thing apart...

...I can't afford this kind of leaning curve...5 grams was a lot of weed to me...

...it was tested @ 28% THC FWIW....

Last edited: