You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Custom CARBLESS VapCap Ti stems

- Thread starter stardustsailor

- Start date

Well-well...

You know that I've turned an old crappy bench -drill (with which I had drilled the last carb holes on my first stem making attempts ) into a rather nice -ehm..guh..- stem working lathe (well it makes my job whola lotta easier .That's something ) .

And now I've just discovered this !

http://www.shobha-india.com/lathe-tools/lathe-tools-d9.html

A hand tool for knurling ?

But then :

https://www.mscdirect.com/browse/tn...ls/Knurl-Holders/Hand-Knurlers?navid=12105917

http://specialtytooling.eaglerockonline.com/category/hand-knurling-tools

Pretty expensive tool.

Did not expect that ,have to say !

You know that I've turned an old crappy bench -drill (with which I had drilled the last carb holes on my first stem making attempts ) into a rather nice -ehm..guh..- stem working lathe (well it makes my job whola lotta easier .That's something ) .

And now I've just discovered this !

http://www.shobha-india.com/lathe-tools/lathe-tools-d9.html

A hand tool for knurling ?

But then :

https://www.mscdirect.com/browse/tn...ls/Knurl-Holders/Hand-Knurlers?navid=12105917

http://specialtytooling.eaglerockonline.com/category/hand-knurling-tools

Pretty expensive tool.

Did not expect that ,have to say !

That’s frustrating! I suppose it’s such a niche tool that it’d be hard to find a second hand one also.

How much do your stems tend to cost?

The standard length ( 62 mm ) stems start at 25 Euros and can reach up to 45 euros.

The XL (79 mm )stems start at 30 Euros and can reach up to 50 Euros.

IPrice depends on the :

a ) Type of texture or finish and

percentage of textured surface and/or number of bands

("band" = a textured area wider than 5 mm defined by thin grooves )

b ) number of rings ( two thin grooves defining a -textured or not- band from 3 to 5 mm wide = "ring " )

c ) type of "corona" ( tip end ) and type of moutpiece ( cigarillo ,lip groove ,other )

d) anodising hues and the difficulty of achieving any possible hue combinations.

Last edited:

Those of you that wish to practice your stem designing skills here's your chance :

Use this template and a simple paint or photo editing software

and express that hidden artistic urge and design your own VC titanium stem.

Draw coronas ,rings ,grooves ,design mouthpieces,apply hues .

Note down textures or even apply texture layers .

Feel free to post your work back here.

You never know ...

You might see your design becoming reality !

Many brains can produce far more -and possibly better -ideas

than a single brain,ain't that right ?

Myself I start like this ,also:

Cheers.

Use this template and a simple paint or photo editing software

and express that hidden artistic urge and design your own VC titanium stem.

Draw coronas ,rings ,grooves ,design mouthpieces,apply hues .

Note down textures or even apply texture layers .

Feel free to post your work back here.

You never know ...

You might see your design becoming reality !

Many brains can produce far more -and possibly better -ideas

than a single brain,ain't that right ?

Myself I start like this ,also:

Cheers.

Last edited:

Here is the color chart with most of the hues ( interference colors ) that can be achieved with Ti anodising .

Inside the rectangle are the hues I work with .

https://www.researchgate.net/figure...entation-of-interference-colour-as-a-function

Interference color orders stop at purples,so the chosen hues

belong to either the second or third order. With layer thickness ranging from

~ 145 nm (gold ) to ~ 215 nm ( lime green ) .

I have seen some medical implants anodised up to the fourth order hues -actually that 4th order " melon green" -,but I've never seen the hues of the fifth order (i.e. never seen that apricot -orange hue ).

http://www.dot-coatingusa.com/images/pdf/Titanium-anodizing.pdf

https://www.researchgate.net/figure...or-use-of-1-lambda-and-14-lambda-plates-added

I 've stop offering the first order hues (bronze to purple ) as also the pale first hues of the second order

(dark blue to pale yellow ),due to their limited durability (= thin oxide layer ).

I'm also using a proprietary two-stage anodising method for achieving the highest possible color saturation ( "chroma" )and a long lasting oxide layer ,as also I'm using a special formulated electrolyte for the same exact reasons .

Anodising forms an amorphous crystallic oxide layer ( called " titania " ,which actually is a mineral ) ,

which acts as thermal insulator ,

gives titanium a corrosion resistance similar to that of Platinum

and acts as a kind of "luster" over any texture

(you can feel that something-a layer of some sort - is covering the metal surface ) .

Inside the rectangle are the hues I work with .

https://www.researchgate.net/figure...entation-of-interference-colour-as-a-function

Interference color orders stop at purples,so the chosen hues

belong to either the second or third order. With layer thickness ranging from

~ 145 nm (gold ) to ~ 215 nm ( lime green ) .

I have seen some medical implants anodised up to the fourth order hues -actually that 4th order " melon green" -,but I've never seen the hues of the fifth order (i.e. never seen that apricot -orange hue ).

http://www.dot-coatingusa.com/images/pdf/Titanium-anodizing.pdf

https://www.researchgate.net/figure...or-use-of-1-lambda-and-14-lambda-plates-added

I 've stop offering the first order hues (bronze to purple ) as also the pale first hues of the second order

(dark blue to pale yellow ),due to their limited durability (= thin oxide layer ).

I'm also using a proprietary two-stage anodising method for achieving the highest possible color saturation ( "chroma" )and a long lasting oxide layer ,as also I'm using a special formulated electrolyte for the same exact reasons .

Anodising forms an amorphous crystallic oxide layer ( called " titania " ,which actually is a mineral ) ,

which acts as thermal insulator ,

gives titanium a corrosion resistance similar to that of Platinum

and acts as a kind of "luster" over any texture

(you can feel that something-a layer of some sort - is covering the metal surface ) .

Last edited:

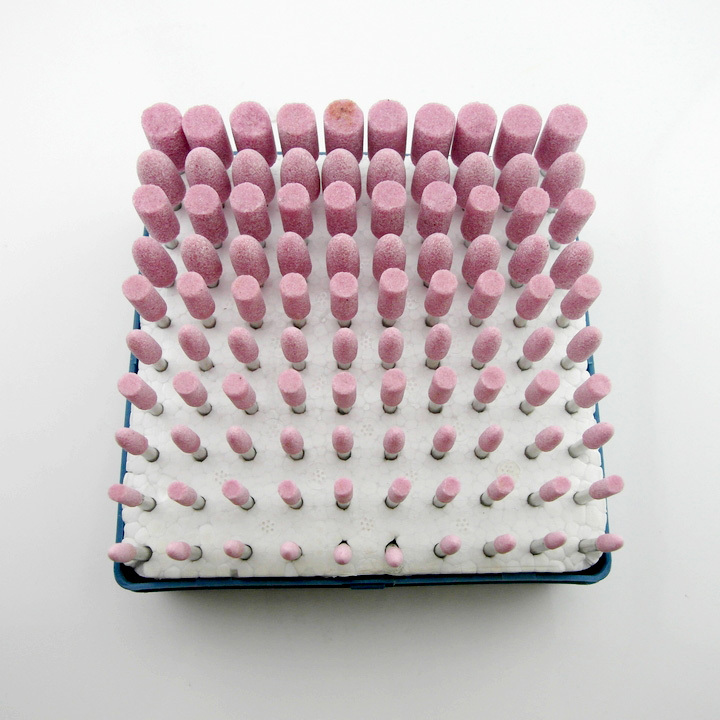

Lately I've been playing with corundum on Titanium.

Corundum is a cheap crystallic mineral also called "ruby" when is deep red colored or

"sapphire " when it has other colors like blue or green.Both the latter forms are not cheap.

For aesthetic reasons mainly.

It's a very hard material,with a hardness value close to diamond .

It comes in " ruby "stone wheels also !

Titanium is very prone to galling .

When a -high speed-rotating corundum stone wheel touches the surface of titanium,

the surface melts locally (due to the poor thermal conductance of titanium ) and titanium

particles / speckles are friction welded nearby.

If the wheel is worked in order to produce a texture between "hammered" and "tree-bark" ,

along with the friction welded particles (due to galling ) it produces a surface that resembles a rock.Limestone or some sort of granite.

Anodising that texture into emerald green - lime green ,it reminded me the Kryptonite.

That fictional green mineral /crystal that can kill superman .

Thus I've named it Kryptonite.

Thing is that while it has quite vibrant iridescent blue-aqua-emerald green-lime green and maybe a bit

of third order yellow ,I can't say that I liked it that much.

Maybe I did not like the first specimen made.

Something about the texture design needs to be revisited.

Or it's just my personal taste .

Anyway,the lad who owns the stem ,seems to like it very much.

I kinda like the idea of a "band" (or a "ring " ) with an "organic" texture .

Hammered ( yes it's quite organic if mirror polished -It resembles a 3D cellular matrix of some sort ),

Tree-bark (no need for further explanation here ),

and now this "rock" texture ,which I'm still not quite sure about ,if it's a keepers.

Particularly on Titanium ,a wide range of such "organic" textures can be achieved.

Thing is that one can not find much info and literature about such work on titanium

(most of Titanium jewellery makers have not gone there ,yet ).

So,I guess I've to experiment further and improvise in order to explore the vast

decorative possibilities that Titanium has to offer.

Corundum is a cheap crystallic mineral also called "ruby" when is deep red colored or

"sapphire " when it has other colors like blue or green.Both the latter forms are not cheap.

For aesthetic reasons mainly.

It's a very hard material,with a hardness value close to diamond .

It comes in " ruby "stone wheels also !

Titanium is very prone to galling .

When a -high speed-rotating corundum stone wheel touches the surface of titanium,

the surface melts locally (due to the poor thermal conductance of titanium ) and titanium

particles / speckles are friction welded nearby.

If the wheel is worked in order to produce a texture between "hammered" and "tree-bark" ,

along with the friction welded particles (due to galling ) it produces a surface that resembles a rock.Limestone or some sort of granite.

Anodising that texture into emerald green - lime green ,it reminded me the Kryptonite.

That fictional green mineral /crystal that can kill superman .

Thus I've named it Kryptonite.

Thing is that while it has quite vibrant iridescent blue-aqua-emerald green-lime green and maybe a bit

of third order yellow ,I can't say that I liked it that much.

Maybe I did not like the first specimen made.

Something about the texture design needs to be revisited.

Or it's just my personal taste .

Anyway,the lad who owns the stem ,seems to like it very much.

I kinda like the idea of a "band" (or a "ring " ) with an "organic" texture .

Hammered ( yes it's quite organic if mirror polished -It resembles a 3D cellular matrix of some sort ),

Tree-bark (no need for further explanation here ),

and now this "rock" texture ,which I'm still not quite sure about ,if it's a keepers.

Particularly on Titanium ,a wide range of such "organic" textures can be achieved.

Thing is that one can not find much info and literature about such work on titanium

(most of Titanium jewellery makers have not gone there ,yet ).

So,I guess I've to experiment further and improvise in order to explore the vast

decorative possibilities that Titanium has to offer.

Last edited:

AtomicPB

Well-Known Member

Just came across your thread by accident (was reading around in the VC thread) and was so impressed by your work that I read the complete thread and admired the posted pictures.

Nice to have some great accessorys for the VapCap coming from Europe. So much easier with customs.

At some point I will most definitely order from you (VAS stripped me of my money this month already). I bet my girlfriend would love your stems as well. I just can't tell her about it yet to surprise her with one.

And I probably would find something I like for myself as well.

Looking forward to your announcement about the new designs and everything. Great stuff.

Nice to have some great accessorys for the VapCap coming from Europe. So much easier with customs.

At some point I will most definitely order from you (VAS stripped me of my money this month already). I bet my girlfriend would love your stems as well. I just can't tell her about it yet to surprise her with one.

And I probably would find something I like for myself as well.

Looking forward to your announcement about the new designs and everything. Great stuff.

Yes,if the stem is going to be used with an OMNI XL condenser it also needs couple of modifications:Does the 62 m9m fit the OMNIVAP XL?

1) No mouthpiece taper ."MP" end has to have "square cut " end /corner ,as the OMNI XL condenser has it's own mp.

2) A carbhole needs to be drilled at the stem.OMNI models operate in accordance with a carbhole.

And before you ask ,yes, I can drill a carbhole ( despicable me ! ) -with a finger notch ,if desired - at different hole diameters ( 1mm / 1,5 mm / 2 mm / 2,5 mm / 3 mm / 3,2 mm / 3,5 mm ).

Cheers.

SuperD

Super

Yes,if the stem is going to be used with an OMNI XL condenser it also needs couple of modifications:

1) No mouthpiece taper ."MP" end has to have "square cut " end /corner ,as the OMNI XL condenser has it's own mp.

2) A carbhole needs to be drilled at the stem.OMNI models operate in accordance with a carbhole.

And before you ask ,yes, I can drill a carbhole ( despicable me ! ) -with a finger notch ,if desired - at different hole diameters ( 1mm / 1,5 mm / 2 mm / 2,5 mm / 3 mm / 3,2 mm / 3,5 mm ).

Cheers.

Thanks I actually am trying to make one like yours but in blue. Thought this one looked great.

Is that the hammered texture with green anodized on it?

Thanks I actually am trying to make one like yours but in blue. Thought this one looked great.

Is that the hammered texture with green anodized on it?

No it's the "rock" texture anodised green = "Kryptonite "

It needs corundum ( usually pink colored ) grinding wheels on a dremel ,to be replicated.

Last edited:

SuperD

Super

So I just went through this whole thread. And I really liked that crosshatch one. I'm also amazed by your anodized paintings really cool work. I'm just learning about the vapcaps and I like the custom stems people have got through here. Is it hard to put one together? Know i need to make a custom mouth peice but does the condenser still get put in? Sorry for all the questions but I really appreciate the help. I want to make sure I have everything for when I order the stem.

So I just went through this whole thread. And I really liked that crosshatch one. I'm also amazed by your anodized paintings really cool work. I'm just learning about the vapcaps and I like the custom stems people have got through here. Is it hard to put one together? Know i need to make a custom mouth peice but does the condenser still get put in? Sorry for all the questions but I really appreciate the help. I want to make sure I have everything for when I order the stem.

I can't give a real answer to that.

For me making a stem is challenging and fun .

Yet ,it is relatively easy for me to shape,sculpt and anodise titanium stems.

I can only answer for myself .

In general ,Titanium is not the easiest and safest material to work with.

Thank you !Beautiful work! Very nice.

Added to my shopping list.

Ahhhh,those shopping lists ...Mine contains other things .

And ain't that cheap ,unforrtunately.

But I'm always hopping to make more of you happy

and maybe at a moment my whishes will be fulfilled too .

And yet they are related to evolving further my craftmanship into creating custom stems ...

My current - 1000 € worth - biggest wish is this austrian beauty :

Cheers.

Last edited:

Yes i think so too.You gonna need it S. if more people find your gorgeous stems!(sounds a bit strange no?)

I 've plenty of ideas in my mind ,more than just the knurled stems .

Titanium stash / storage tubes ,just for an example.

Squiby

Well-Known Member

I 've plenty of ideas in my mind ,more than just the knurled stems .

Titanium stash / storage tubes ,just for an example.

Can't wait!!!! When are planning to reveal some of your new offerings

SuperD

Super

I'm not sure about what's your asking me.@stardustsailor

What did u use for your mouthpiece?

I suppose you're asking about which tools were used to make the mp " radius edge " ?

Rough with ordinary files (medium and fine grit ) and then finish with Silicon Carbide sandpapers

( EU fine grits 400 & 600 and EU extra fine 2500 grit ) .

Cheers.

As promised .

Can somebody take careful (as precise as possible ) measurements of a 14 mm male bong joint ?

Can these numbers below at the red highlighted area be verified as correct ?

Something new came up in my mind .

Thanx in advance .

Cheers.

http://www.technicalglass.com/product_pages/fused_quartz_labware/joints/standard_taper_joints.html

http://www.bacto.com.au/glass-conical-joint-sizes/

Can these numbers below at the red highlighted area be verified as correct ?

Something new came up in my mind .

Thanx in advance .

Cheers.

http://www.technicalglass.com/product_pages/fused_quartz_labware/joints/standard_taper_joints.html

http://www.bacto.com.au/glass-conical-joint-sizes/

Last edited:

snackmaster

Well-Known Member

Can somebody take careful (as precise as possible ) measurements of a 14 mm male bong joint ?

Can these numbers below at the red highlighted area be verified as correct ?

Something new came up in my mind .

Thanx in advance .

Cheers.

http://www.technicalglass.com/product_pages/fused_quartz_labware/joints/standard_taper_joints.html

http://www.bacto.com.au/glass-conical-joint-sizes/

I have some that match the 14/23 dims, but others 14/20.